- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shenglin

-

Liquid Flow Rate:

-

3m/s

-

Maximum Working Pressure:

-

4MPa

-

Weight:

-

80 KG

-

Dimension(L*W*H):

-

1000*450*520mm

-

Warranty:

-

12month

-

Working Temperature Range:

-

-5-50

-

tube material:

-

copper, aluminum, SS304, SS316L

-

type:

-

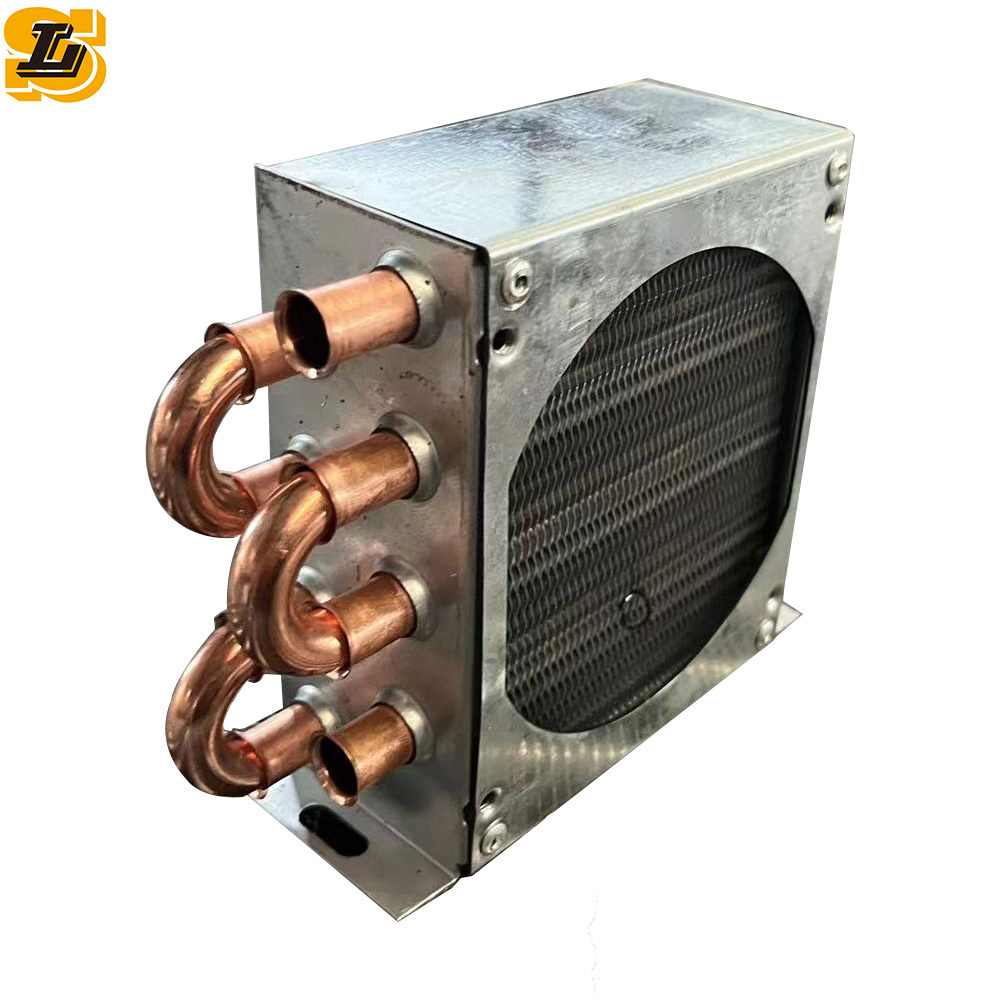

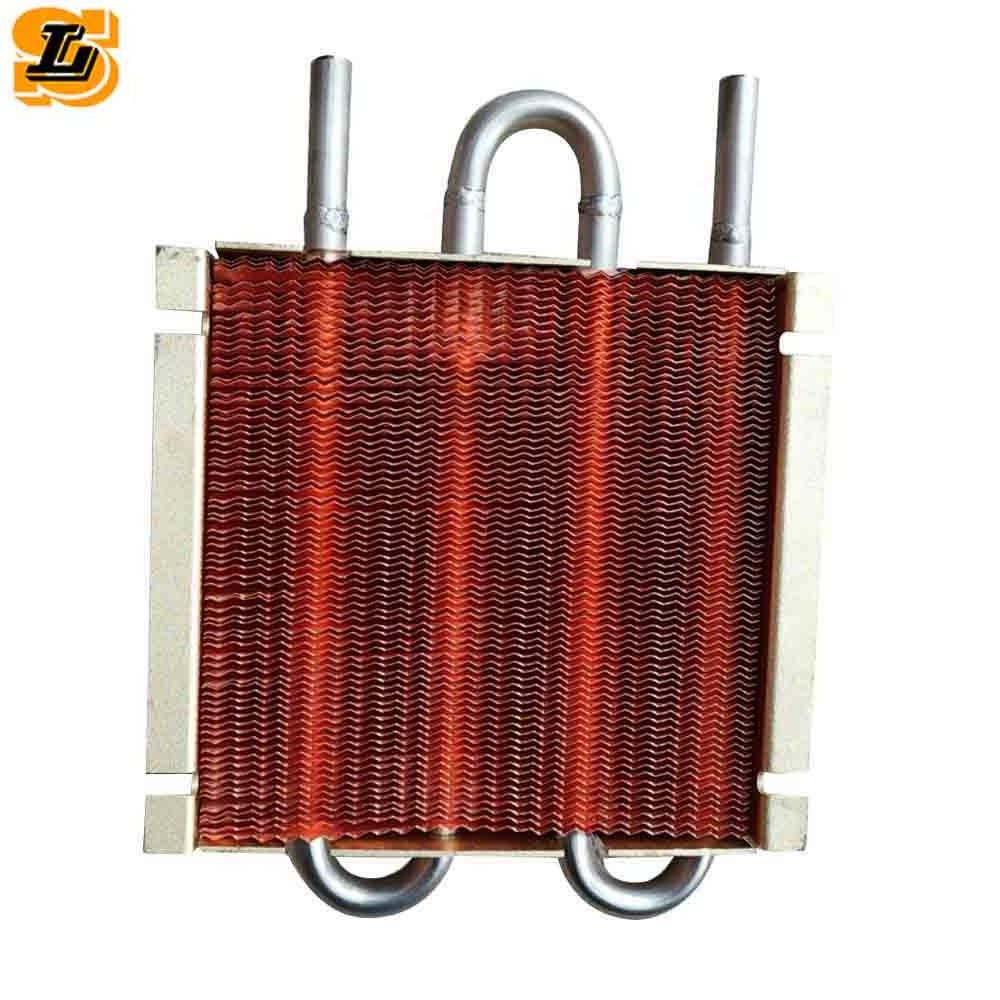

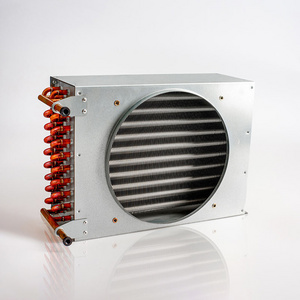

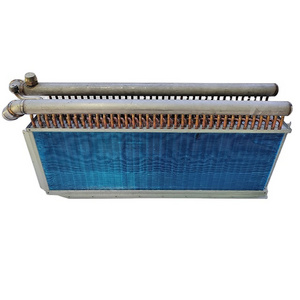

tube finned stainless steel heat exchanger freon water

-

fin material:

-

aluminium, conpper, stainless steel

-

plate material:

-

copper,aluminum,stainless steel

-

design serice:

-

be viable

-

tube thickness:

-

0.45mm

-

fin type:

-

flat fin, sine wave, window fin

-

fin thickness:

-

0.12mm

-

plate thickness:

-

1.5mm

-

fin coating:

-

epoxy coated, bare fin, hydropjilic fin, E-coating

Quick Details

-

Structure:

-

heat exchanger freon water

-

Voltage:

-

200v

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shenglin

-

Liquid Flow Rate:

-

3m/s

-

Maximum Working Pressure:

-

4MPa

-

Weight:

-

80 KG

-

Dimension(L*W*H):

-

1000*450*520mm

-

Warranty:

-

12month

-

Working Temperature Range:

-

-5-50

-

tube material:

-

copper, aluminum, SS304, SS316L

-

type:

-

tube finned stainless steel heat exchanger freon water

-

fin material:

-

aluminium, conpper, stainless steel

-

plate material:

-

copper,aluminum,stainless steel

-

design serice:

-

be viable

-

tube thickness:

-

0.45mm

-

fin type:

-

flat fin, sine wave, window fin

-

fin thickness:

-

0.12mm

-

plate thickness:

-

1.5mm

-

fin coating:

-

epoxy coated, bare fin, hydropjilic fin, E-coating

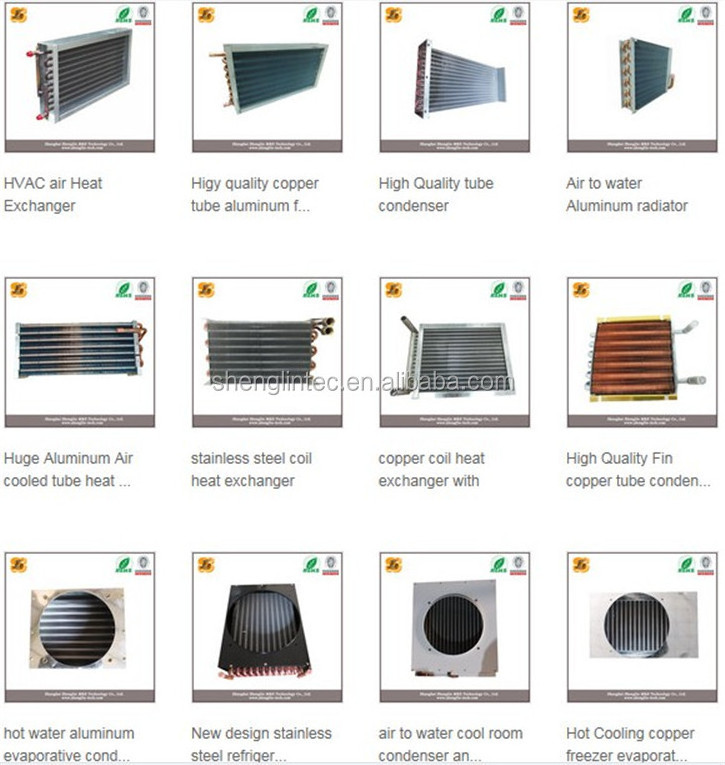

tube finned stainless steel heat exchanger freon water

tube finned stainless steel heat exchanger freon water Specification:

| Raw material | Tube O.D.: Φ 7, Φ 7.94, Φ 9.52, Φ 12.75, Φ 15.88. | |||

|

Tube material: Copper tube (inner smooth or inner grooved); aluminum tube; stainless steel tube, titanium tube, ect. |

||||

| Fin material: copper fin; aluminum fin; stainless steel fin, ect. | ||||

| Bare, hydrophilic Al foil(green antibacterial hydrophilic Al foil or slica antibacterial Al foil ) | ||||

| Fin coating: hydrophilic aluminum fin; epoxy coating; electrophoretic; sandblasting, ect. | ||||

| Side plate: galvanized steel; aluminum; ect. | ||||

| Application | Air conditioner, refrigeration, freezer, cold room… | |||

| Key process |

Tube bending, Punching the fins, Tube expanding, Degreasing, Welding and assembling, Leakage test, Drying, (Bending), Inspection, Packing |

|||

| Performance | Can satisfy the capability requirements | |||

| Capacity | 4.0 million sets per year (12500sets per day) | |||

| Residual moisture | ≤ 25 / | |||

| Residual impurity | ≤ 30 / | |||

1.High performance

2.The sub cooler integrated with the condenser further cools the liquid

refrigerant, resulting in increased refrigerant enthalpy and improved

evaporator cooling performance

3. Thinner tubes and fins improve the heat exchange rate

4. Smaller header tank and lower side plate height increase the effective

heat exchange area of the core part that exchanges heat, without

increasing the installation space

5.Small size, light weight and easy installation

6.The tube's zinc diffusion layer improves corrosion resistance, resulting in reduced tube plate thickness

1. We charge for samples. If we have the samples you need in stock, we can send it to you within one week after received payment.

2. We can also manufacture samples according to your drawings or samples; lead time depends on the actual production status in our factory.