- Product Details

- {{item.text}}

Quick Details

-

Equipment Capacity:

-

10 tons per day

-

Weight (KG):

-

30000 KG

-

Name:

-

recycle Tire Tyre Plastic Oil Sludge cable sheath Pyrolysis Machine

-

Raw material:

-

Q235R Boiler Plate

-

Function:

-

waste to oil fuel energy

-

Capacity:

-

10tons per day

-

Color:

-

Customers' Demand

-

after sales:

-

engineer can guide installation and train workers operation

-

Area need:

-

300 square meters

-

Power:

-

15kw

-

size:

-

D2600*6600mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

sihai

-

Marketing Type:

-

New Product 2023

-

Equipment Capacity:

-

10 tons per day

-

Weight (KG):

-

30000 KG

-

Name:

-

recycle Tire Tyre Plastic Oil Sludge cable sheath Pyrolysis Machine

-

Raw material:

-

Q235R Boiler Plate

-

Function:

-

waste to oil fuel energy

-

Capacity:

-

10tons per day

-

Color:

-

Customers' Demand

-

after sales:

-

engineer can guide installation and train workers operation

-

Area need:

-

300 square meters

-

Power:

-

15kw

-

size:

-

D2600*6600mm

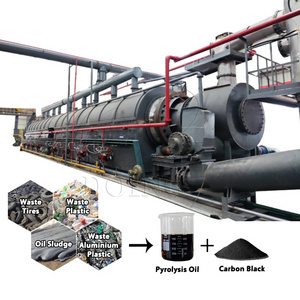

professional export to South Korea recycle Tire Tyre Plastic Oil Sludge Pyrolysis Machine

Does not have to get rid of silt, moisture content, iron wire impurity and so on from the scrap plastic, directly loads in the rotary system high temperature atmospheric pressure split processor, catalyses, heats up, distils oil steam, the oil gas through the condenser, the liquefied part condense into the oil mixture, and the unliquefied part holds through the fuel gas system into the processor bottom to burn. After the mixture oil condense, put into fractionation processor to heat through catalytic reforming process, and get the oil steam. Then the oil steam through the condenser to be basic fuel, and add various additives to become qualified fuel.

| LJ-8 | LJ-9 | LJ-10 | LJ-11 | LJ-12 | |

| raw material |

tire/plastic/ rubber/oil slage |

tire/plastic/ rubber/oil slage |

tire/plastic/ rubber/oil slage |

tire/plastic/ rubber/oil slage |

tire/plastic/ rubber/oil slage |

| capacity | 5tons per day | 8tons per day | 10tons per day | 12tons per day | 15tons per day |

| reactor structure |

horizontal

|

horizontal | horizontal | horizontal | horizontal |

| reactor size | 2.2m*6.0m | 2.2m*6.6m | 2.6m*6.6m | 2.8m*6.6m | 2.8m*7.7m |

| working pressure | atmospheric | atmospheric | atmospheric | atmospheric | atmospheric |

| cooling system | water | water | water | water | water |

| heating method | direct | direct | direct | direct | direct |

| power | 12kw | 12kw | 15.5kw | 15.5kw | 16Kw |

| package | 2*40HC | 2*40HC | 1*40HC+1**40FR | 1*40HC+1*40FR | 1*40HC+1*40FR |

| area need | 300sqm | 300sqm | 300sqm | 300sqm | 300sqm |

| workers need | 2~3workers | 2~3workers | 2~3workers | 2~3workers | 2~3workers |

| life | 5~8years | 5~8years | 5~8years | 5~8years | 5~8years |

| installlation | free | free | free | free | free |

| environment | no pollution | no pollution | no pollution | no pollution | no pollution |

Packing Details : 2*40HQ or 1*40HQ+1*40FR Seaworthy

Delivery Details : 20~30 days after the deposit

We can send our engineer to your side for guiding the installation and training your workers operation.