- Product Details

- {{item.text}}

Quick Details

-

Model:

-

TLYW5-TLYW100

-

Capacity:

-

1-100m3/hour sewage

-

Voltage:

-

380V /220V

-

Usage:

-

dairy industry water treatment

-

Function:

-

remove oil and suspsended solids

-

Certification:

-

ISO9001

-

Material:

-

Carbon Steel/stainless steel

-

Warranty:

-

1 year

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

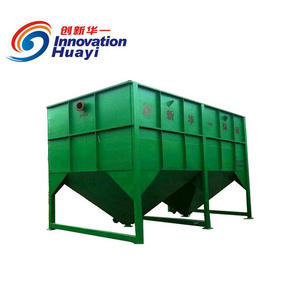

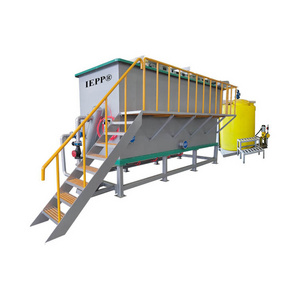

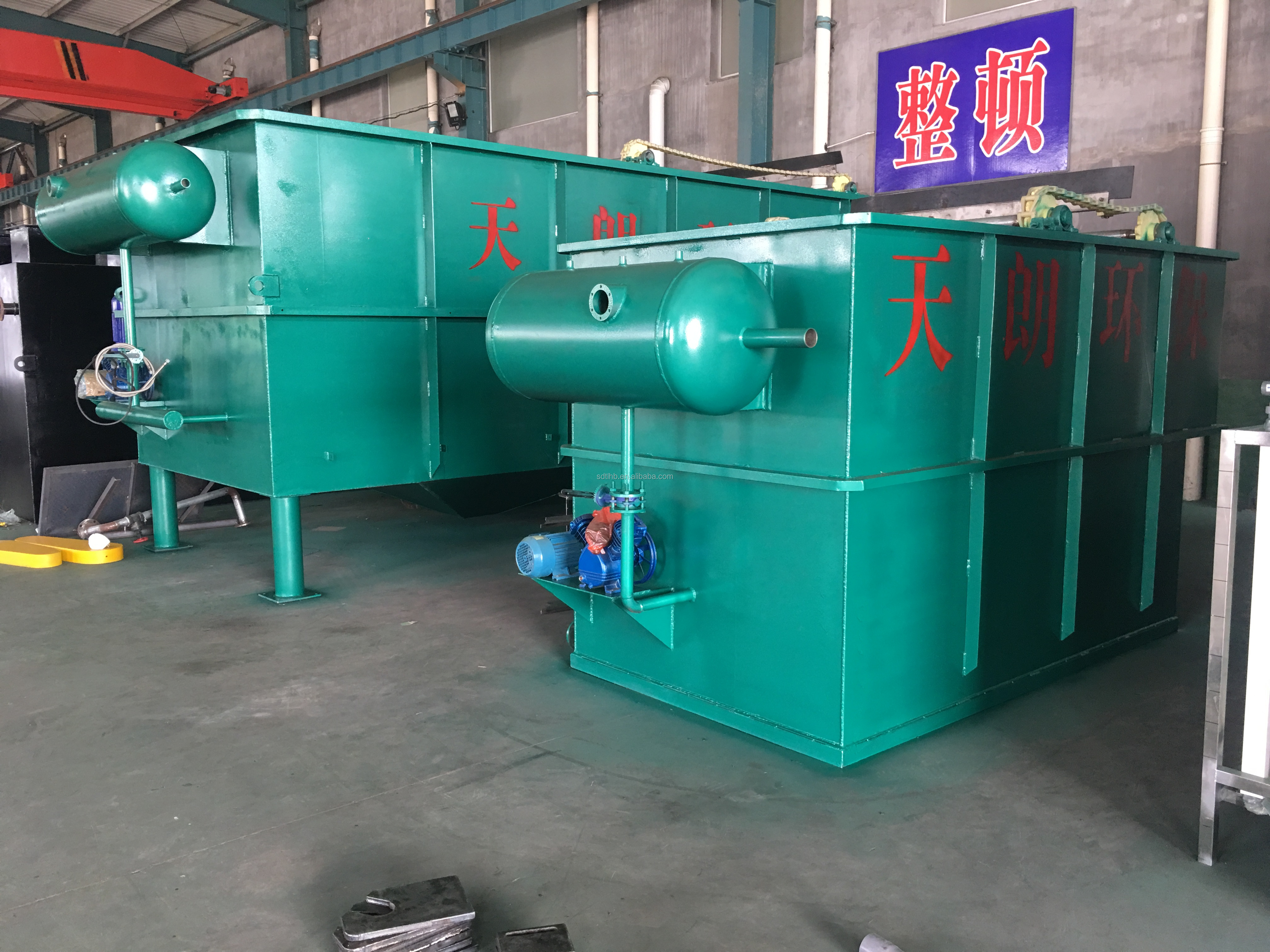

DAF wastewater treatment clarifier for dairy industry water treatment

-

Color:

-

blue/green/customized by clients

-

Model:

-

TLYW5-TLYW100

-

Capacity:

-

1-100m3/hour sewage

-

Voltage:

-

380V /220V

-

Usage:

-

dairy industry water treatment

-

Function:

-

remove oil and suspsended solids

-

Certification:

-

ISO9001

-

Material:

-

Carbon Steel/stainless steel

-

Warranty:

-

1 year

dissolved air flotation machine small daf unit for sewage treatment

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries , petrochemical and chemical plants , natural gas processing plants , paper mills, general water treatment and similar industrial facilities.

(1) Remove oil and TSS.

(2) Separate small particles and algae in groundwater.

(3) Recover valuable products in industrial sewage such as paper pulp.

(4) Act as secondary sedimentation tank to separate and concentrate suspended particles and sludge.

(1) Large capacity, high efficiency and small occupying space.

(2) Compact structure, easy operation and maintenance.

(3) Silt expansion elimination.

(4) Aerate to the water while air floating, it has an obvious effect to the elimination of active agent and foul smell in water. Meanwhile, the increased dissolved oxygen provides a favorable condition to the follow-up process.

(5) It can achieve the best effect in adopting this method when disposing the water with lower temperature, lower turbidity and more algae.

|

Model |

Capacity (m3/h) |

Motor power(kw) |

Scraper power(kw) |

Air compressor power(kw) |

Dissolved air tank |

Overall size |

|

TLYW-5 |

4-5 |

3 |

0.55 |

0.75 |

Φ400*1000 |

2800*2100*2200 |

|

TLYW-10 |

8-10 |

3 |

0.55 |

0.75 |

Φ 500*1512 |

3700*2100*2200 |

|

TLYW-15 |

10-15 |

4 |

0.55 |

1.5 |

Φ 500*1512 |

4500*2200*2300 |

|

TLYW-20 |

15-20 |

5.5 |

1.5 |

Φ 500*1512 |

4650*2400*2300 |

|

|

TLYW-30 |

20-30 |

5.5 |

0.75 |

1.5 |

Φ 500*1512 |

5840*2700*2300 |

|

TLYW-40 |

35-40 |

7.5 |

0.75 |

1.5 |

Φ 600*1880 |

6800*2700*2300 |

|

TLYW-50 |

45-50 |

0.75 |

2.2 |

Φ 600*1880 |

7500*2900*2300 |

|

|

TLYW-60 |

55-60 |

7.5 |

1.1 |

2.2 |

Φ 600*1880 |

8500*2900*2300 |

|

TLYW-70 |

65-70 |

11 |

1.1 |

3 |

9000*2900*2300 |

|

|

TLYW-80 |

75-80 |

11 |

1.1 |

3 |

Φ 650*1800 |

10800*3000*2500 |

|

TLYW-100 |

95-100 |

15 |

1.5 |

4 |

Φ 700*1900 |

11500*3000*2500 |

Note: we can design the different size based on the different water capacity(m3/h).

Based on different water source and different water quality, The feed water to the DAF float tank is often (but not always) dosed with Flocculant and coagulant (such as PAC and PAM) to coagulate the colloidal particles and a flocculant to conglomerate the particles into bigger clusters .

A portion of the clarified effluent water leaving the DAF tank is pumped into a small pressure vessel (called the air drum) into which compressed air is also introduced. This results in saturating the pressurized effluent water with air. The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction valve just as it enters the front of the float tank,which results in the air being released in the form of tiny bubbles. Bubbles form at nucleation sites on the surface of the suspended particles, adhering to the particles. As more bubbles form, the lift from the bubbles eventually overcomes the force of gravity. This causes the suspended matter to float to the surface where it forms a froth layer which is then removed by a skimmer. The froth-free water exits the float tank as the clarified effluent from the DAF unit.

Based on water quality, we can add sedimentation device at the bottom of the DAF machine, it can make the particles (such as sludge, sand) that easy to sedimentation setting into the bottom of tank .