- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1830x2150x2750, 1830x2150x2750

-

Weight:

-

2 KG

-

Key Selling Points:

-

capacity large

-

Name:

-

Galvanized Steel feed Storage Silo

-

Usage:

-

Pig chicken farm

-

Silo Materials:

-

Galvanized Steel Sheet

-

Volume:

-

2-30 Tons

-

Custom Design:

-

yes

-

Thickness:

-

1mm

Quick Details

-

Core Components:

-

/

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yinglian

-

Dimension(L*W*H):

-

1830x2150x2750, 1830x2150x2750

-

Weight:

-

2 KG

-

Key Selling Points:

-

capacity large

-

Name:

-

Galvanized Steel feed Storage Silo

-

Usage:

-

Pig chicken farm

-

Silo Materials:

-

Galvanized Steel Sheet

-

Volume:

-

2-30 Tons

-

Custom Design:

-

yes

-

Thickness:

-

1mm

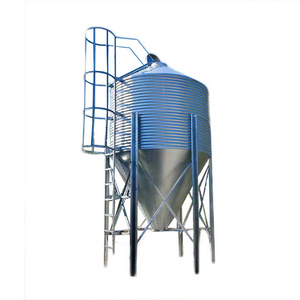

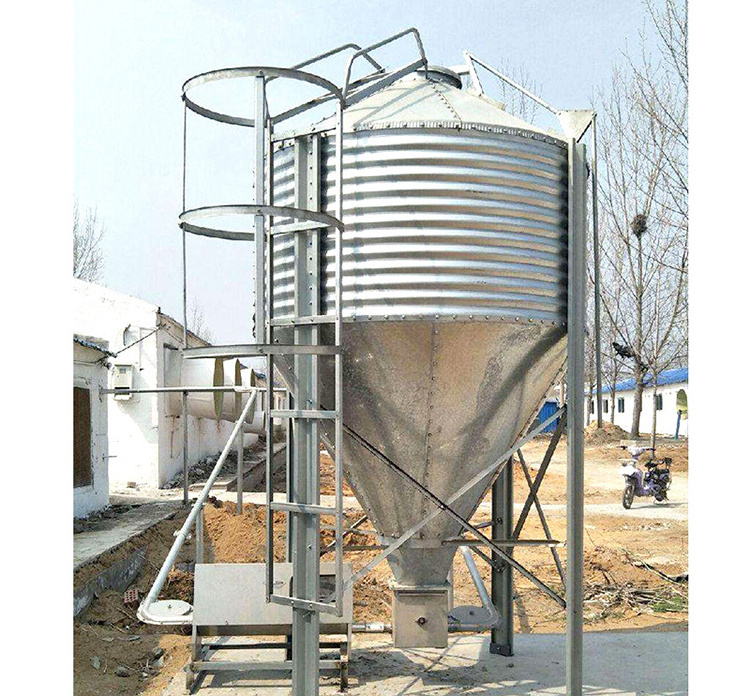

Chicken Poultry Feed Silo Galvanized Sheet Auger Silo Chicken Automatic Feeding Line System Feed Storage Silo

With the advanced numerical controlled equipment, feed silos feature low product data error, high precision and the leading stability of international standards. We select a dedicated outdoor galvanized plate, which has the advantage of corrosion-resistant and long life span. The adoption of international advanced technology and the unique angle design ensure feed drop more smoothly.

Silo consists of main warehouse, flip, ladders, columns, and other components. the main warehouse used 275g/m2, double hot dip galvanized sheet steel, has a lower conical hole to view feed level. silo volume according to different actual combinations. Hoarding water in a slope, in the hordings at the bottom flange, so that rainwater away from the cutting area. Provide weather protection , regardless of the weather. the next round head screw connection cone inside, effectively reducing cutting resistance. Upper and lower cone by pressure off treatment, both to improve the cone and strength of cone bottom's overall, but also conducive to bilateral clay bar installation, enhanced sealing.

Feed silo is an important component of the main feeding system. This system includes feed silo or hopper, conveying PVC pipe, auger or chain - disc, drop outlets, feed bin, feed senser and driving motor.

This system is mainly used to convey feed from the feed silo or hopper into the feed bin to achieve the aim of automatically feeding.

Using silos could save the labor force and save large amounts of packages, also keep feeder fresh and health and reduce raising costs greatly.

1). Silo body constructed with hot-galvanized corrugated steel plate; zn-coat thickness≥275g per square meter.

2).All the hole was punched, in order to protect the zinc coating.

3). Silo body1.0-1.5mm thickness hot galvanized plate., Normal anticorrosive ability >13 years

4). The top and bottom of silo boday is 1.0-1.5mm thickness hot galvanized plate.

5). The stents and stairs is 3.0mm thickness hot galvanized plate.

6). All steel plate joints are fixed by M10X25 and M8X20 bolts and seal gums, ensuring no leaking seams, security and long operating life.

7). High-quality plates, for more than 30-year service life.

|

Volume/m^3 |

Capacity MT |

Diameter/mm |

Height/mm |

Layers |

Material |

Stent Number |

|

4.7 |

3T |

1900 |

3700 |

1 |

Galvanized plate(275g/m^2) |

4 |

|

7.5 |

5T |

2160 |

4400 |

1 |

4 |

|

|

10.3 |

7T |

2160 |

5600 |

2 |

6 |

|

|

16.5 |

10.5T |

2680 |

5860 |

2 |

6 |

|

|

22.3 |

14T |

2680 |

6800 |

3 |

6 |

|

|

25.4 |

16T |

3180 |

6200 |

2 |

8 |

|

|

31 |

20T |

3180 |

7100 |

3 |

8 |

|

|

34.6 |

23.5T |

3670 |

6180 |

2 |

8 |

|

|

41.5 |

28T |

3670 |

7200 |

3 |

8 |

>>>Click Here To Get More Information From Us Now

Poultry automatic drinking system line and feeding line system

Packing:

For packing,most of products we packed into carton boxes,some special goods are packed with wooden frame. It's according to products

Shipping:

We can ship by sea, air or courier transport according to your requirements or ship the goods to your designated freight forwarding. For larger products, it is recommended to choose to ship, if it is a reagent or a smaller machine with the reagent transport, we recommend the use of air or courier.

1. By courier like DHL, FedEx, TNT, UPS, EMS, etc. It is door to door, 5-10 working days to arrive.

2. By air to the airport,5-10 working days to arrive.

3. By sea, 30-60 working days to arrive.

4. Customers specifying freight forwarders or negotiable shipping methods.