- Product Details

- {{item.text}}

Quick Details

-

Drilling Speed:

-

2840r/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGQIANG

-

Model Number:

-

MZ73211/MZB21A

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1900*2600*1300mm

-

Power (kW):

-

1.5

-

Weight (KG):

-

350 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

multi head drilling machine OEM:

-

optional

-

multi head drilling machine use:

-

MDD,particleboard,plywood,PVC boad,plexiglass,and solid wood plate

-

multi head drilling machine pre.:

-

0.5-0.8Mpa

-

multi head drilling machine dep.:

-

0-60mm

-

multi head drilling machine distance:

-

32mm

-

multi head drilling machine workpiece:

-

2500*920*70mm

-

multi head drilling machine spindles:

-

21

-

multi head drilling machine Type:

-

One randed

-

multi head drilling machine Warranty:

-

12 months

Quick Details

-

type:

-

horizontal

-

Max. Drilling Dia. (mm):

-

35

-

Range of Spindle Speed(r.p.m):

-

1 - 2840 r.p.m

-

Drilling Speed:

-

2840r/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGQIANG

-

Model Number:

-

MZ73211/MZB21A

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1900*2600*1300mm

-

Power (kW):

-

1.5

-

Weight (KG):

-

350 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

multi head drilling machine OEM:

-

optional

-

multi head drilling machine use:

-

MDD,particleboard,plywood,PVC boad,plexiglass,and solid wood plate

-

multi head drilling machine pre.:

-

0.5-0.8Mpa

-

multi head drilling machine dep.:

-

0-60mm

-

multi head drilling machine distance:

-

32mm

-

multi head drilling machine workpiece:

-

2500*920*70mm

-

multi head drilling machine spindles:

-

21

-

multi head drilling machine Type:

-

One randed

-

multi head drilling machine Warranty:

-

12 months

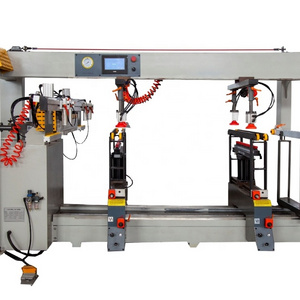

product overview

FEATURES

1.apply to processin all kinds of density boards ,shaving boards,wood-based panels ,PVC boards ,organic glass plates and soild

wood drilling

2. full-boady cast iron structure of the base .Vertical tank ,horizontal seat ,left and right panels ,motors and other key parts

of base is also used in all cast iron

3.electrical components are imported ,true color touch screen cntrol system ,the equipment more stable ,easy to operate

4.apply double support ,big beam design ,enhancethe stability of the machine

1.apply to processin all kinds of density boards ,shaving boards,wood-based panels ,PVC boards ,organic glass plates and soild

wood drilling

2. full-boady cast iron structure of the base .Vertical tank ,horizontal seat ,left and right panels ,motors and other key parts

of base is also used in all cast iron

3.electrical components are imported ,true color touch screen cntrol system ,the equipment more stable ,easy to operate

4.apply double support ,big beam design ,enhancethe stability of the machine

Details Images

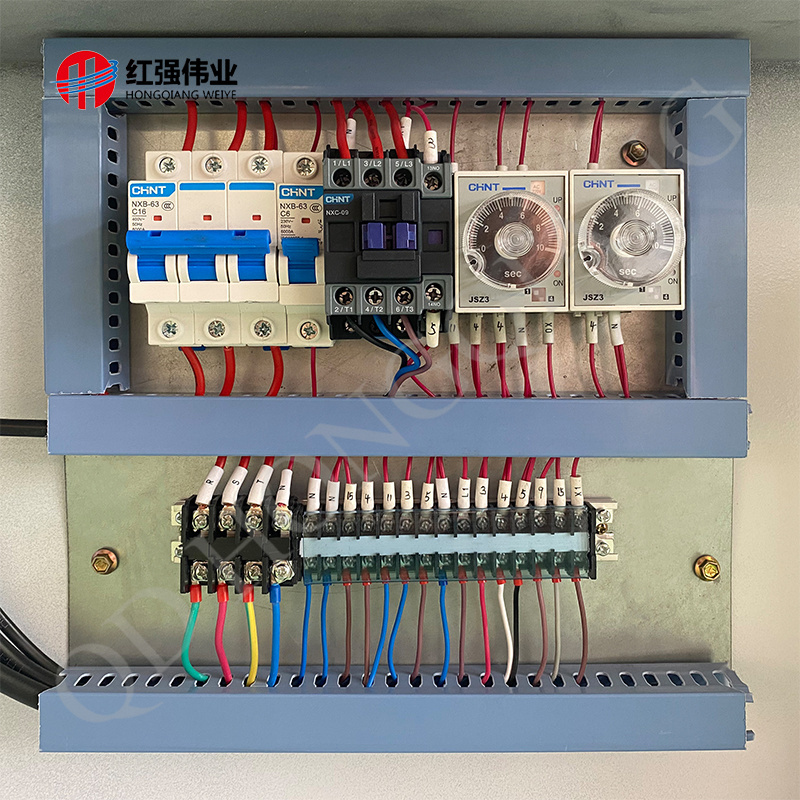

electric parts

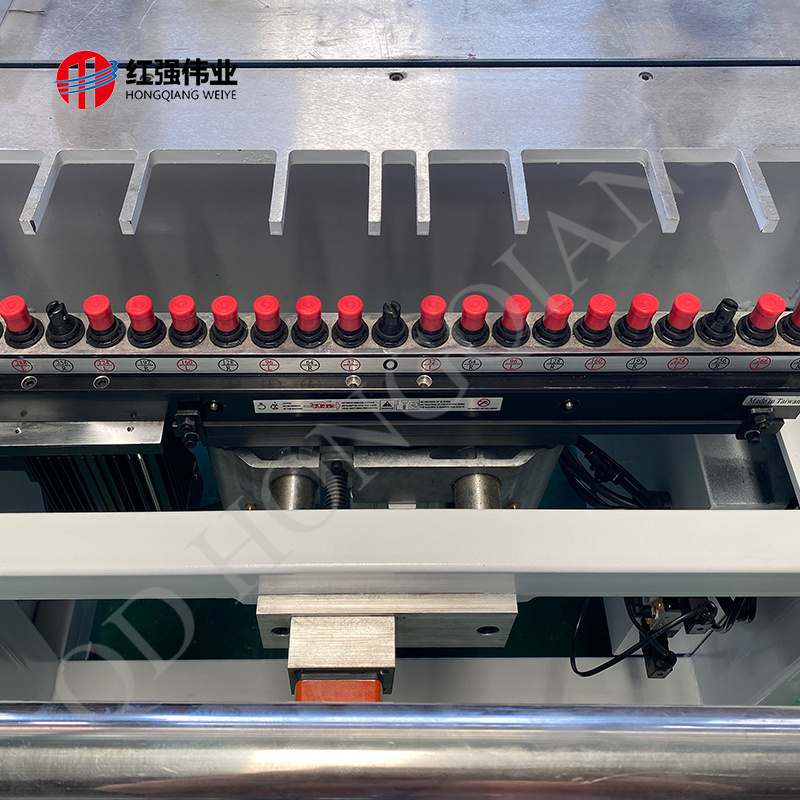

drilling rows

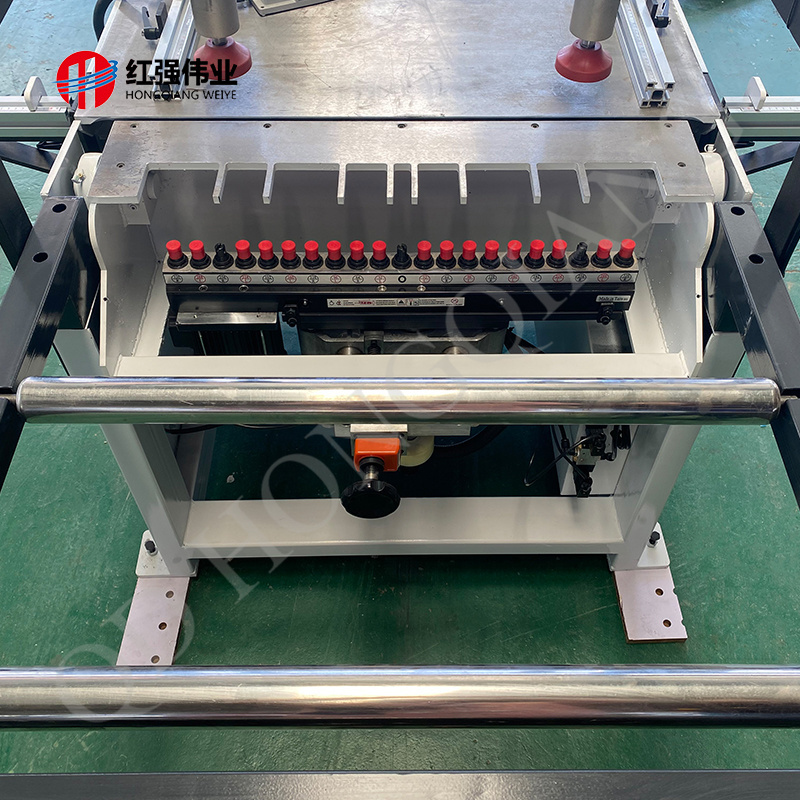

vertical and horizontal drilling

Water separator

Product Paramenters

|

Model

|

MZ73211

|

|

Max diameter of holes

|

35mm

|

|

Depth of drilled holes

|

0-60mm

|

|

Number of spindles

|

21

|

|

Rotation of spindle

|

2800r/min

|

|

Motor power

|

1.5kw

|

|

Voltage

|

220/380v,50hz

|

|

Overall dimensions

|

1400*1300*1400mm

|

|

Air pressure

|

0.6-0.8mpa

|

|

Net weight

|

350kg

|

Application

Customer Photos

Delivery and package

Recommend Products

Our Service

Pre-sale services

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, we offer the reasonable plan and free design helping to select the equipment.

4> Welcome to visit our factory

Services during the sales

1> Inspect the machine before leaving the factory.

2> Oversea install and debug the equipment.

3> Train the first-line operator.

After sale services

1> 24 hours online service

2> Provide the VIDEO with Install and debug the equipment

3> Provide technical exchanging

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, we offer the reasonable plan and free design helping to select the equipment.

4> Welcome to visit our factory

Services during the sales

1> Inspect the machine before leaving the factory.

2> Oversea install and debug the equipment.

3> Train the first-line operator.

After sale services

1> 24 hours online service

2> Provide the VIDEO with Install and debug the equipment

3> Provide technical exchanging

Hot Searches