- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RotexMaster

-

Voltage:

-

380V/415v/440v

-

Dimension(L*W*H):

-

2200*1300*1600

-

Motor Power (Kw):

-

132

-

Power (kW):

-

132

-

Weight (KG):

-

5800 KG

-

Marketing Type:

-

Other

-

Product name:

-

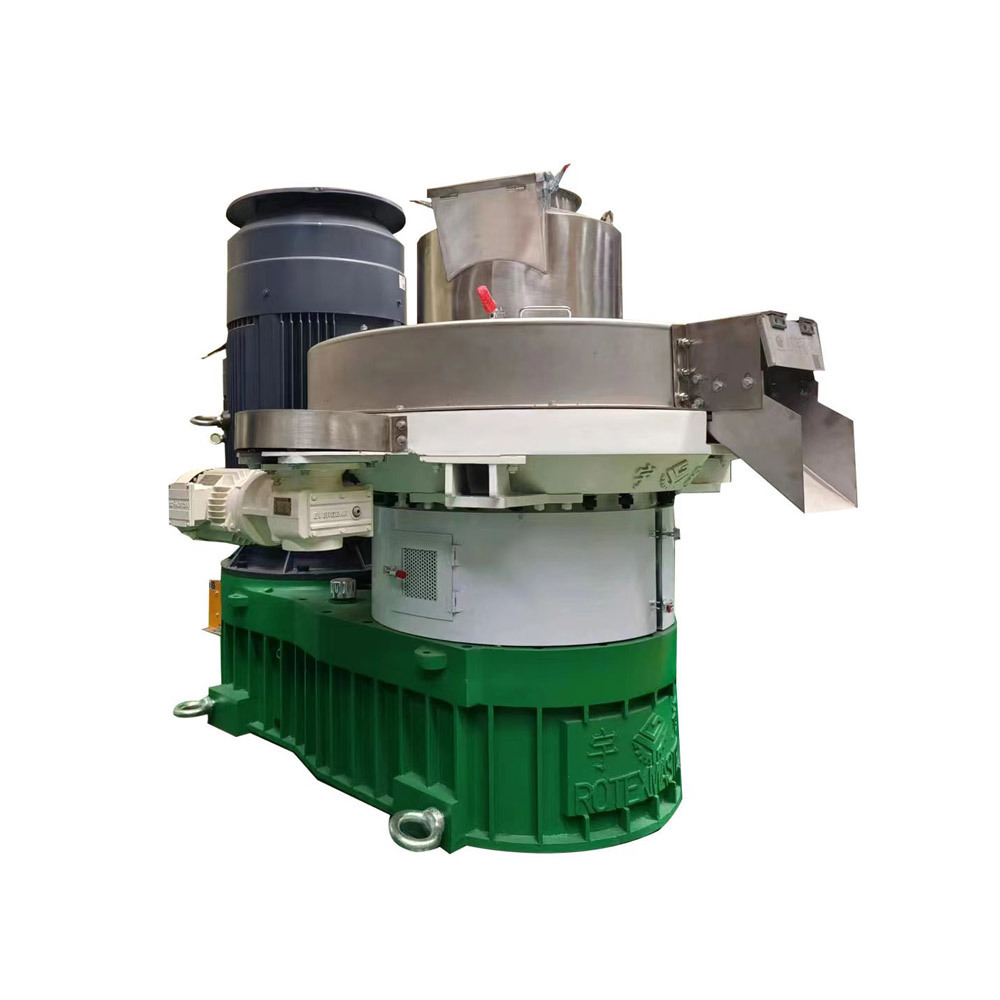

Biomass Straw Wood Sawdust Rice Husk Alfalfa Pellet Making Machine

-

Usage:

-

Making Biomass Pellets

-

Raw material:

-

all kinds of wood, agricultural straw, rice husk, biomass waste

-

Ideal moisture:

-

13-15%

-

Machine type:

-

Vertical Ring Die

-

Motor:

-

SIEMENS Brand

-

Spare parts:

-

Ring Die, Rollers

-

Process:

-

chipping-crushing-drying-pelleting-cooling-packing

-

Installation:

-

Onsite Install

-

Service:

-

Service

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1500 - 2000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RotexMaster

-

Voltage:

-

380V/415v/440v

-

Dimension(L*W*H):

-

2200*1300*1600

-

Motor Power (Kw):

-

132

-

Power (kW):

-

132

-

Weight (KG):

-

5800 KG

-

Marketing Type:

-

Other

-

Product name:

-

Biomass Straw Wood Sawdust Rice Husk Alfalfa Pellet Making Machine

-

Usage:

-

Making Biomass Pellets

-

Raw material:

-

all kinds of wood, agricultural straw, rice husk, biomass waste

-

Ideal moisture:

-

13-15%

-

Machine type:

-

Vertical Ring Die

-

Motor:

-

SIEMENS Brand

-

Spare parts:

-

Ring Die, Rollers

-

Process:

-

chipping-crushing-drying-pelleting-cooling-packing

-

Installation:

-

Onsite Install

-

Service:

-

Service

Product Description

Introduction of

Biomass Straw Wood Sawdust Rice Husk Alfalfa Pellet Making Machine

The

Biomass Straw Wood Sawdust Rice Husk Alfalfa Pellet Making Machine

(also wood pellet mill) is the latest pellet machinery in China. The biomass wood pellet machine adopts a large modulus hard toothed helical gearbox, strengthened spindle, strong power output, equipment stable operation, low failure rate, low production.

Biomass Waste Sawdust Straw into Wood Pellets

suitable for: eucalyptus, pine, birch, poplar, fruit, crop straw, bamboo chips, rice husk, waste wood plate, etc

The finished pellets is biomass energy as biofuel, which can replace coal, oil, gas, etc., widely used in power plant, boiler, and heating system.

Specification

|

Model

|

Main Power(kw)

|

Capacity(t/h)

|

Dimension(L*W*H)

|

Weight(t)

|

|

YGKJ560

|

132

|

1.5-2

|

2200*1300*1600

|

5.8

|

|

YGKJ700

|

160

|

2-3

|

2400*1400*1800

|

7.8

|

|

YGKJ880

|

220

|

3-4

|

3000*1500*2200

|

13

|

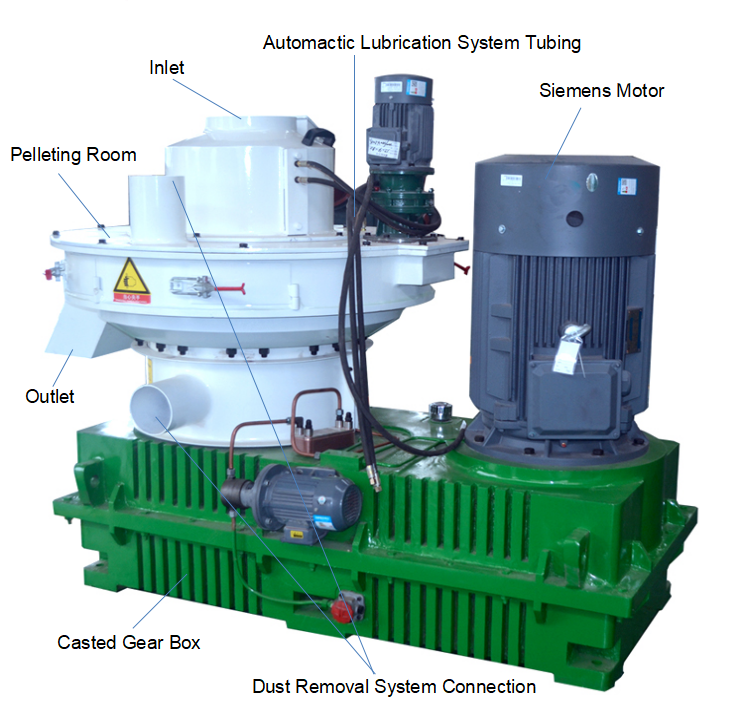

Details Images

Stainless Steel Mould

Stainless steel whole carburizing die,high wear resistance, good stability,discharge area increase,enhance capacity and reduce cost.Double layer,both side can be used, reduce cost.

Roller

the roller adopts wear-resistant alloy welding process, without lock nut structure design, less grease consumption, which greatly extends the bearing life, then reducing cost.

Siemens Motor

The motor of

wood pellet maker

is frequency, with thick copper coil, It won’t be burned due to instantaneous current.

Reducer

The gearbox adopts independent research and development big 3 level drive,module increased , gear strengths increased, carrying more and more ability.The service life increased 8-10 times than the traditional reducer,greatly increase the service life.

Air Cooling System

Adopt air cooling, circulation cooling, cooling gear oil inside the gear box

Automatic oiling system

Reducer and main shaft bearing chamber adopts loop closed industrial gear oil lubrication,make lubrication effect more outstanding,reduce the cost of traditional grease lubrication, add a circulating waste cooling oil temperature cooling device, reduce the oil temperature in reducer, protect bearings.

Raw Material and Application

What kind of raw materials can be used to make biomass pellets?

There are many different raw materials can be used in the biomass wood pellet production line, for example wood log, wood chips, wood sawdust, rice hush, straw, palm shell, EFB, wet or dry grass, alfalfa, hemp, tire fiber, organic fertilizer, waste paper, and so on.

Application of wood pellets

Applications: Make Biomass Pellets, Biomass Industry, Burning, Making Wood Fuel etc.

Main Process to Press Wood Pellets

Different material need different machine. Take wood log as a example,the whole process include:

Drum wood chipper-To make wood log into small size wood chips.

Hammer mill/Crusher-To make wood chips into sawdust

Dryer-To dry the high moisture content of sawdust into 12-15%

Drum wood chipper-To make wood log into small size wood chips.

Hammer mill/Crusher-To make wood chips into sawdust

Dryer-To dry the high moisture content of sawdust into 12-15%

Packing & Delivery

Rotexmaster can provide clients delivery service, we are professional in helping each clients

Customer Photos

10tph Pellet Line in Philippines

8 sets of new wood pellet machine

5-6t/h Wood Pellet Line in Thailand

.

20t/h Pellet Production Line in Asia

5-6t/h Wood Pellet Line in Malaysia

New Wood Pellet Line

5-6t/h Wood Pellet Line in Thailand

20t/h Wood Pellet Line in Cambodia

10t/h Wood Pellet Line

Hot Searches