- Product Details

- {{item.text}}

Quick Details

-

Power:

-

220KW

-

Dimension(L*W*H):

-

3670x2517x2050

-

Weight (KG):

-

11840

-

Color:

-

Customer Required

-

Model:

-

BX2113

-

Raw material:

-

Straw Grass Wood Branches

-

Type:

-

Blade Cruhser

-

Item:

-

Wood Grinding Grinder Crusher

-

Key selling points:

-

Easy to operate

-

Rotary knife raw materials:

-

Manganese /H13 steel (optional)

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ABX

-

Voltage:

-

380V, 380/400/460/415/440

-

Power:

-

220KW

-

Dimension(L*W*H):

-

3670x2517x2050

-

Weight (KG):

-

11840

-

Color:

-

Customer Required

-

Model:

-

BX2113

-

Raw material:

-

Straw Grass Wood Branches

-

Type:

-

Blade Cruhser

-

Item:

-

Wood Grinding Grinder Crusher

-

Key selling points:

-

Easy to operate

-

Rotary knife raw materials:

-

Manganese /H13 steel (optional)

specifications

|

Model

|

BX213

|

BX215

|

BX216

|

BX218

|

BX2113

|

|

Inlet Size(m)

|

120×300

|

160*400

|

230*500

|

300*680

|

450*700

|

|

Knife No.(pc)

|

2

|

2

|

2

|

2

|

3

|

|

Knife roller rotate speed(rpm)

|

730

|

592

|

590

|

650

|

500

|

|

Max Dia of raw material(mm)

|

120

|

160

|

230

|

300

|

450

|

|

Wood chips size(mm)

|

30

|

30

|

30

|

30

|

30

|

|

Capacity(t)

|

1-3

|

3-4

|

7-8

|

10-15

|

15-30

|

|

Main Motor Power(kw)

|

30

|

45

|

55

|

110

|

220

|

|

Feeder Motor Power(kw)

|

1.1*2

|

2.2-3

|

3-4

|

4-5

|

7.5*2

|

|

Oil Pump Motor Power(kw)

|

1.1

|

1.5

|

1.5

|

1.5

|

3

|

|

Weight(kg)

|

1200

|

2990

|

4070

|

7000

|

11840

|

|

Overall Dimension(mm)

|

1540*2150*1020

|

1470×1550×970

|

1800×1900×1210

|

3980×2150×1900

|

3670x2517x2050

|

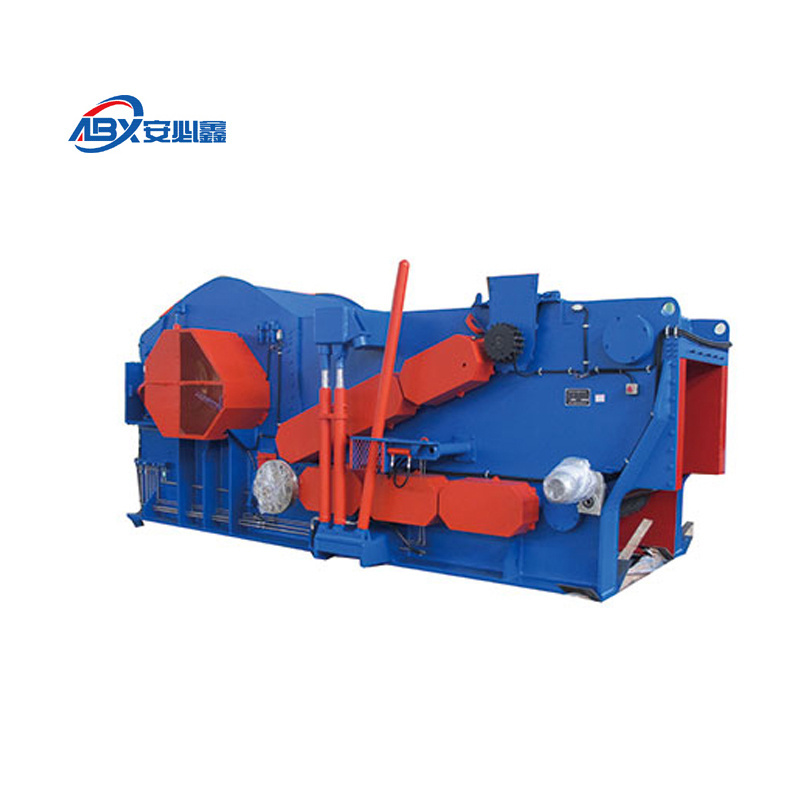

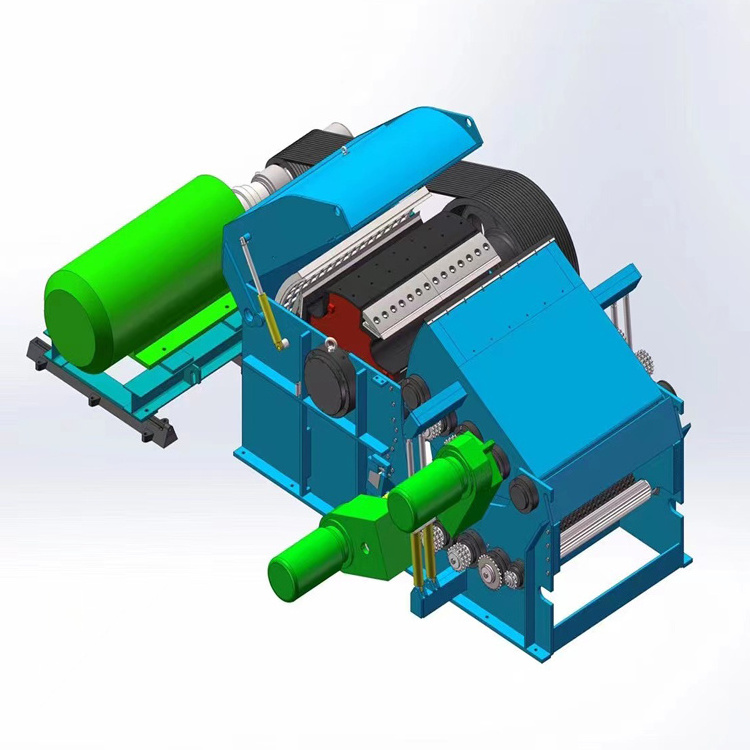

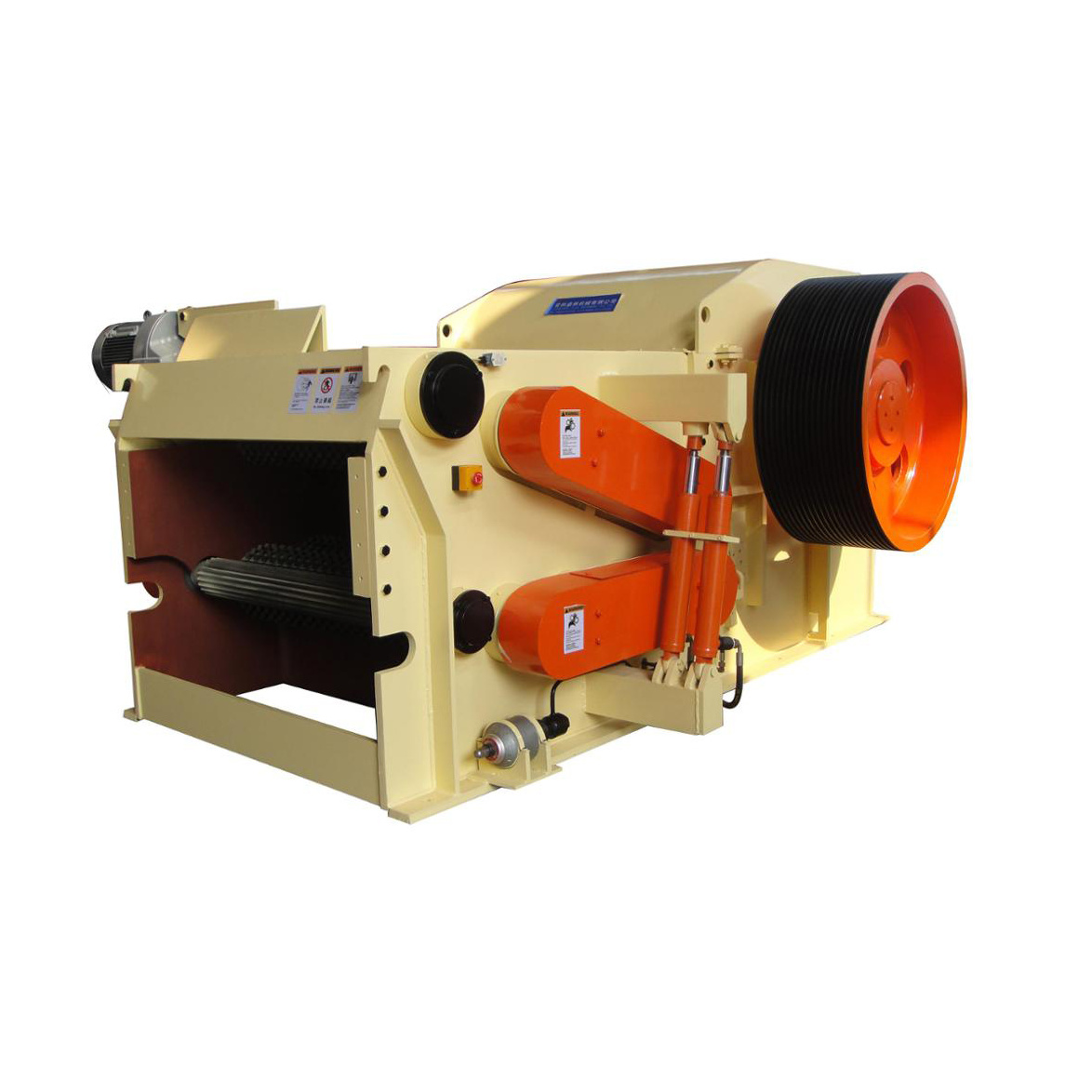

Product Display

Industrial wood cutting chipper specifications sales price:

1. The product has advanced structure, high quality cutting blade material, convenient operation and maintenance. The main cutting materials are small size logs, wood cutting residue (such as branches, boards, strips, core logs, waste veneer, etc.), can also be used for cutting non-wood materials (such as sugarcane, reed, bamboo, etc.).

2, the machine is composed of fuselage, knife roller, upper and lower feeding roller, conveyor, hydraulic system and so on.

1) The body is welded with high strength steel plate, which is the supporting foundation of the whole machine.

2) Install two, three and four knives on the knife roller, and fix the knife on the knife roller with special knife bolts through the pressing block. Depending on the thickness of the cutting material, the upper feed roller assembly can fluctuate within a certain range through the hydraulic system. Qualified pieces are cut and dropped through the sieve hole, discharged from the bottom, and large pieces are cut in the machine.

3) Hydraulic system: from the oil pump to the oil cylinder, can start the cap, convenient to replace the blade; During maintenance, the upper feeding roller assembly can be lifted, the clearance of knife bottom can be adjusted and the comb plate can be easily disassembled.

4) In and out of the belt conveyor can be customized according to your requirements.

Product parameters

Hot Searches