- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

5500x1500x1200mm

-

Weight:

-

5000 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot products

-

Product name:

-

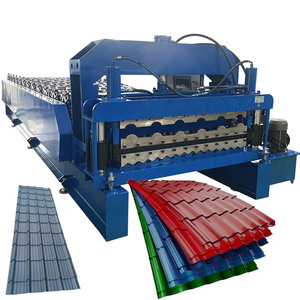

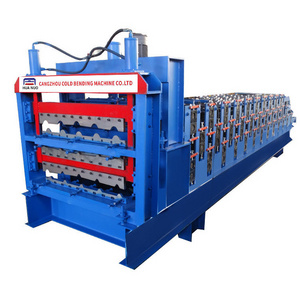

Three layer roll forming machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15-20 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

5500x1500x1200mm

-

Weight:

-

5000 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot products

-

Product name:

-

Three layer roll forming machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Products Description

Metal glazed tile roofing panel roll forming machine

The glazed tile roof roll forming machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Work processing

Specification

|

Metal glazed tile roofing panel roll forming machine

|

|

|

|

|||

|

SN

|

Part details

|

Item

|

Specification

|

|||

|

1

|

Material

|

Raw material

|

Galvanized steel or PPGI

|

|||

|

|

|

Thickness

|

0.3-0.8 mm

|

|||

|

2

|

Machine

|

Roller station

|

Depend on customer' drawing

|

|||

|

|

|

Shaft diameter

|

70 mm

|

|||

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Roller material hardness 30-40 HRC

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Machine size

|

About 5.5*1.5*1.2m

|

|||

|

|

|

Machine weight

|

About 5 ton

|

|||

|

|

|

Machine color

|

As customer' request

|

|||

|

|

|

Working speed

|

15-20 m/min

|

|||

|

3

|

Cutter

|

Hardness

|

50-65 HRC

|

|||

|

|

|

Cutting tolerance

|

± 1 mm

|

|||

|

|

|

Material

|

Cr 12

|

|||

|

|

|

Operate

|

Hydraulic cutting

|

|||

|

4

|

Power

|

Driving way

|

Chain 1 inch

|

|||

|

|

|

Main power

|

7.5 kw

|

|||

|

|

|

Pump power

|

5.5kw

|

|||

|

|

|

Voltage

|

Customize as customer' request

|

|||

|

5

|

Control system

|

PLC brand

|

Delta or Customize as customer' request

|

|||

|

|

|

Screen

|

Touchable screen

|

|||

|

|

|

Language

|

English or add language as customer need

|

|||

|

6

|

Decoiler

|

Operation

|

Manual

|

|||

|

|

|

Weight capicatity

|

5 ton

|

|||

|

|

|

Price

|

Free as gift

|

|||

|

7

|

Receiving table

|

Operation

|

Manual

|

|||

|

|

|

Length

|

3 m

|

|||

|

|

|

Price

|

Free as gift

|

|||

Product Details

5T Manual Decolier For Free

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 1220mm

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine.

Feeding Device

Hand wheels on both sides can be used to adjust the feeding width.

Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

PLC Control Box

Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic Pump Station

Hydraulic station motor: 4 KW

Hydraulic oil:46# hydraulic oil

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve.

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve.

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Sample Room

Finished product effect for your reference.

The following are the products produced by our machine. Please check the rolling forming effect.

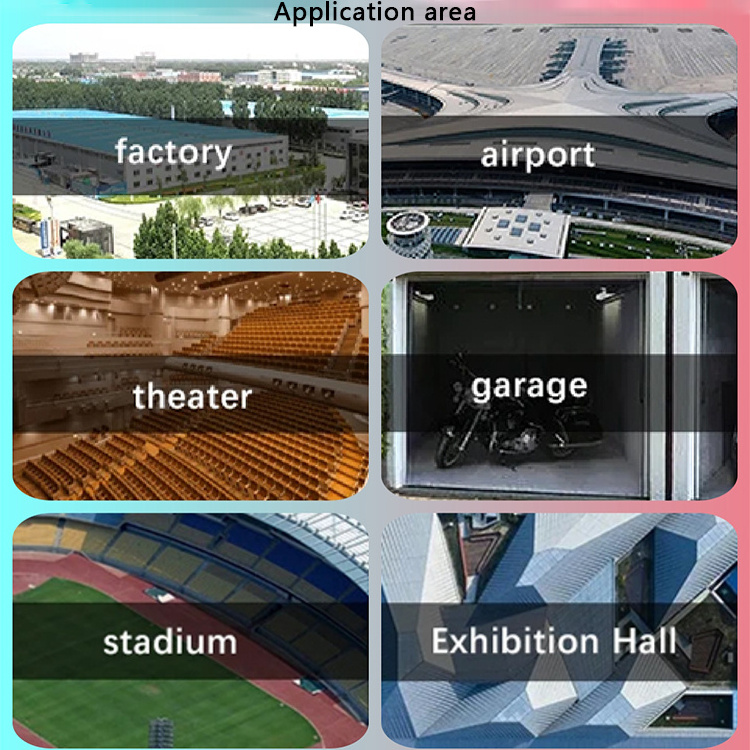

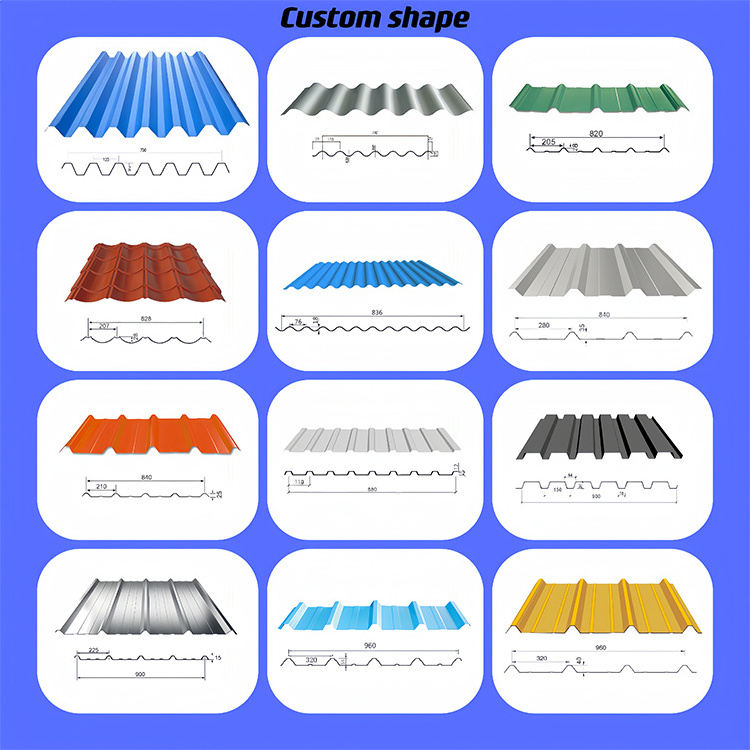

Related Plate Type

Glazed Tile Type Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Other Product

Packing&Delivery

Hot Searches