- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends on the capacity of boiler

-

Weight:

-

Depends on the capacity of size

-

Product name:

-

Biomass hot water boiler

-

Installation method:

-

Quick installation boiler

-

Outlet pressure:

-

low pressure

-

Boiler Usage:

-

Living boiler

-

boiler type:

-

Hot water boiler

-

Water level volume:

-

≥30L

-

Rated thermal power:

-

<0.1MW

-

Rated steam pressure:

-

<0.1Mpa

-

Outlet water pressure:

-

<0.1MPa

-

Working water pressure:

-

>0.3MPa

Quick Details

-

Core Components:

-

Boiler main body

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Anxin

-

Dimension(L*W*H):

-

Depends on the capacity of boiler

-

Weight:

-

Depends on the capacity of size

-

Product name:

-

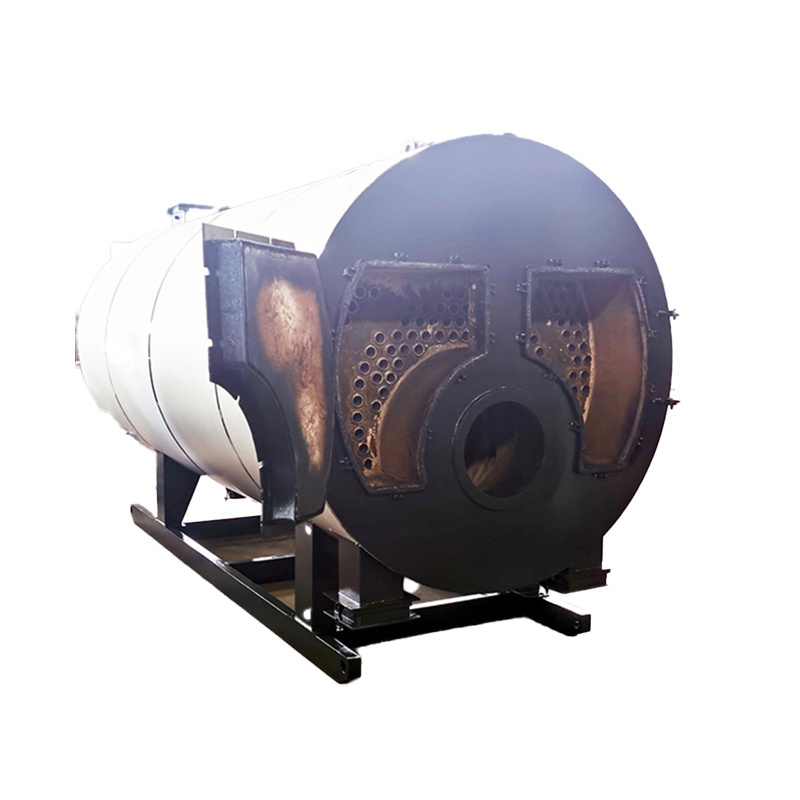

Biomass hot water boiler

-

Installation method:

-

Quick installation boiler

-

Outlet pressure:

-

low pressure

-

Boiler Usage:

-

Living boiler

-

boiler type:

-

Hot water boiler

-

Water level volume:

-

≥30L

-

Rated thermal power:

-

<0.1MW

-

Rated steam pressure:

-

<0.1Mpa

-

Outlet water pressure:

-

<0.1MPa

-

Working water pressure:

-

>0.3MPa

Product Description

Specification

|

CWNS

|

0.35MW-14MW

|

85/65

|

–Y(Q)

|

|

Horizontal atmospheric hot water boiler

|

Rated thermal power

|

Effluent/return water

|

Heating source: oil (gas)

|

|

Product Features

|

|

|

|

|

||||

|

1. Adopting an internal combustion wet back flue gas three return structure, the structure is reasonable and compact.

|

|

|

|

|

||||

|

2. The boiler adopts threaded smoke pipes with internal turbulence devices to enhance heat transfer and greatly improve thermal efficiency.

|

|

|

|

|

||||

|

3. The front and rear detachable smoke box doors facilitate boiler maintenance and repair.

|

|

|

|

|

||||

|

4. The body can be galvanized as needed to provide clean domestic hot water.

|

|

|

|

|

||||

|

5. Automatic operation is achieved by setting the start and stop temperatures of the combustion engine and circulating water pump,and controlling the system to automatically operate according to the set conditions, while displaying the system's operating conditions and outlet and return water temperatures. Display alarm information when a fault occurs.

|

|

|

|

|

||||

|

6. In manual operation, the circulating water pump and burner can be directly operated. When a malfunction occurs, corresponding instructions will be given and manual operation will be refused to ensure system safety.

|

|

|

|

|

||||

|

7. The smoke outlet can be equipped with a condensing heat exchanger to reduce the exhaust temperature and absorb the sensible and latent heat in the smoke, thereby improving the efficiency of the boiler (up to 95% or more).

|

|

|

|

|

||||

Hot Searches