- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

4700 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Chrome Ore Washing Plant

-

capacity:

-

100-50000tpd

-

Application:

-

Chrome

-

Material:

-

Steel

-

Recovery rate:

-

95-99%

-

Color:

-

Customized Making

-

Installation:

-

Engineer Guide

-

Usage:

-

Chromite Ore Processing Plant

-

Feeding size:

-

0-100mm

-

Keywords:

-

Chromite Ore Beneficiation Plant

Quick Details

-

Production Capacity:

-

5000tpd

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xinhai

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

4700 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Chrome Ore Washing Plant

-

capacity:

-

100-50000tpd

-

Application:

-

Chrome

-

Material:

-

Steel

-

Recovery rate:

-

95-99%

-

Color:

-

Customized Making

-

Installation:

-

Engineer Guide

-

Usage:

-

Chromite Ore Processing Plant

-

Feeding size:

-

0-100mm

-

Keywords:

-

Chromite Ore Beneficiation Plant

Note!!!

The current price is not the actual price, the specific price is subject to the sales quotation.

Product Description

Chrome beneficiation plant

---Product Description

【Introduction】:

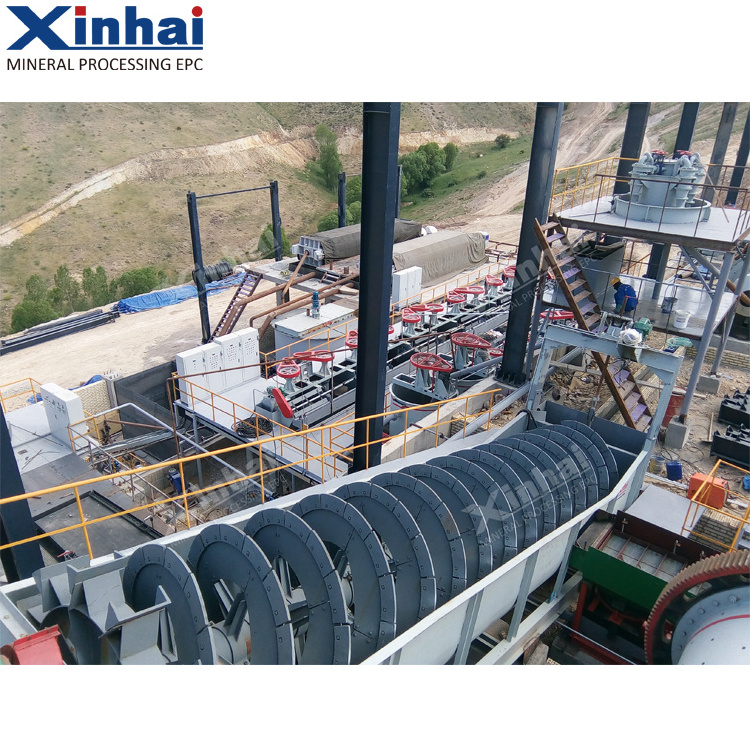

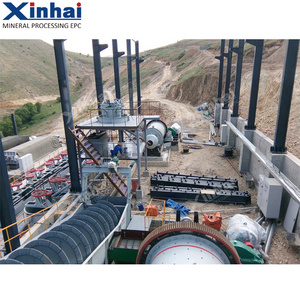

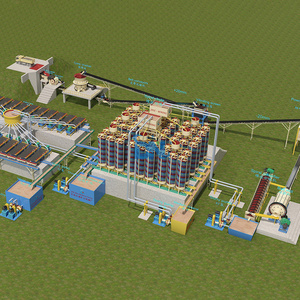

Chrome ore deposits are mined by both underground and surface techniques. Most chrome ore must be processed by the chrome ore processing plants. the mainly chrome ore beneficiation method is gravity separation. So the mainly used chrome ore concentrating equipments are ore washbox (sometimes it is called jigger), concentrating table, spiral classifiers, etc.

Product Application

Chrome Ore Washing Plant

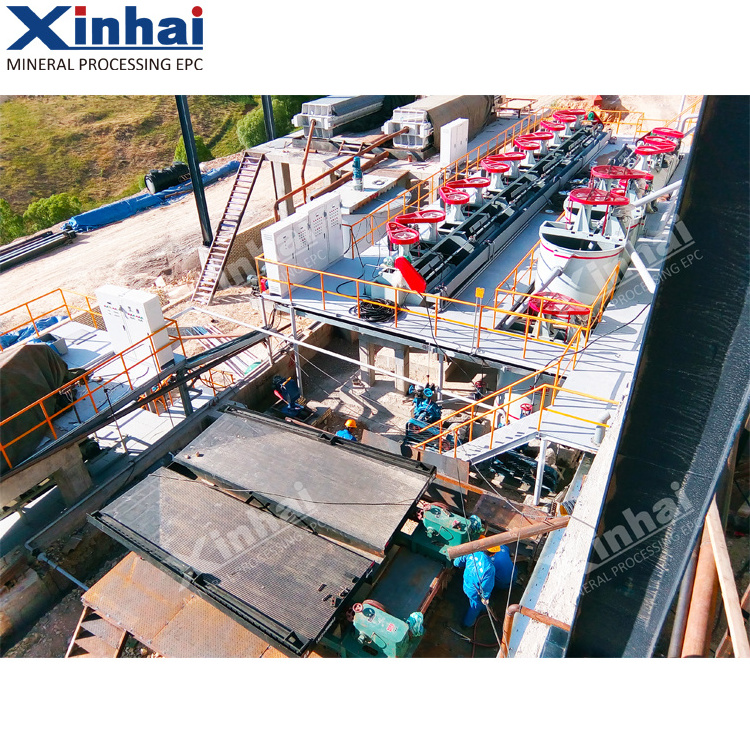

[Application]: The choice of chrome mineral processing technology is closely related with the physical and chemical properties of chrome ores. Because chrome ores are with weak magnetic, high magnetic separation matures gradually in chrome purfication with the technology development. And the magnetic separation has few pollution to the environment. Therefore, chrome magnetic separation gets promoted and applied in mineral processing plants.

Process Description

Chrome beneficiation plant

---Process Description

Processing Technology

For chrome processing technology, there are gravity separation, flotation, magnetic separation and other methods. Xinhai will determine the final processing technology according to the ore characteristic analysis report and mineral processing experiment report.

Gravity Separation

The common gravity separation flows is that: through crushing and grinding, the reasonable fineness of chrome ores are cleaned and classified by the spiral classifier with the help of the different specific gravity of the solid particles and the different precipitation speeds in the liquid.

Then use a jig machine and a shaker to wash the materials and transport them to the spiral chute to sort fine-grained mineral powder.

Flotation or Magnetic Separation

After screening, the slurry is sent to flotation cell or magnetic separator. The concentrates are dewatered after flotation.

Dewatering

After dewatering, the concentrates can be sent to the dryer. The dry concentrates can be directly used or re-grinding to pick up minerals.

Process Flow

Recommend Products

The chrome processing plant mainly include following equipment,You can "

click

" the picture to know more information!

|

crusher

|

screening

|

grinding

|

jig

|

dewatering

|

Mineral Processing EPC+M+O

|

Xinhai devotes to providing “Turn-key Solution for Mineral Processing Plant”, namely “design and research- complete equipment manufacturing and procurement-commissioning and delivery - management and operation”. Up to now, Xinhai has established multiple overseas offices in the world.

|

About Xinhai

Contact Us

Your email address and telephone will not be shared or published!

Please fill in the equipment,ore and capacity that you need and do not forget mail and phone if you like to be contacted.

Please click " send " to contact us

Please fill in the equipment,ore and capacity that you need and do not forget mail and phone if you like to be contacted.

Please click " send " to contact us

Hot Searches