- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JRVAL -010

-

Brand Name:

-

JRVAL

-

Working pressure:

-

0.15~0.8MPa

-

Seal Material:

-

PTFE Seal

-

Working Temperature:

-

10-110

-

Disc:

-

WCB+stainless Steel

-

Name:

-

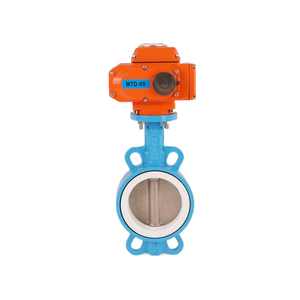

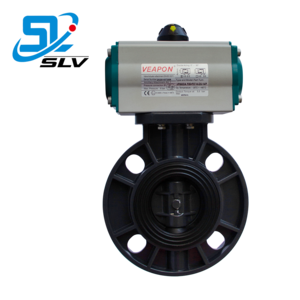

manual butterfly valve for dust pipe

-

Medium:

-

Oil Water Gas

-

Keyword:

-

stainless steel wafer butterfly valve

-

MOQ:

-

1

-

Packing:

-

Carton Box

Quick Details

-

Port Size:

-

50-300

-

Warranty:

-

1 year, 1year

-

Place of Origin:

-

Tianjin, China

-

Model Number:

-

JRVAL -010

-

Brand Name:

-

JRVAL

-

Working pressure:

-

0.15~0.8MPa

-

Seal Material:

-

PTFE Seal

-

Working Temperature:

-

10-110

-

Disc:

-

WCB+stainless Steel

-

Name:

-

manual butterfly valve for dust pipe

-

Medium:

-

Oil Water Gas

-

Keyword:

-

stainless steel wafer butterfly valve

-

MOQ:

-

1

-

Packing:

-

Carton Box

|

Size (inch) |

Face to face (mm) |

Piece weight (kgs) |

Thickness of body (mm) |

Thickness of upper flange (mm) |

|

3 |

45.2 |

4.9 +/- 5% |

7.5 |

12.3 |

|

4 |

51.9 |

6.0 +/- 5% |

7.5 |

13 |

|

5 |

53.5 |

8.0 +/- 5% |

7.5 |

13.5 |

|

6 |

54.2 |

9.5 +/- 3% |

8.9 |

14.5 |

|

8 |

58.5 |

15.0 +/- 3% |

1.2 |

16 |

1. Check whether the specifications, pressure, temperature and corrosion resistance of the butterfly valve meet the requirements before use. Inspect all parts for damage or looseness.

2. This butterfly valve can be installed on pipelines with any angle. It should be closed for installation. When welding pipeline flanges, the valve sealing mouth should be blocked with a plate to prevent particles and debris from contaminating the sealing surface. After welding, remove the valve, Clean the sealing surface and the inner cavity of the pipe before installing the fixed valve.

3. Before installation, wipe the sealing surfaces (both sealing surfaces at both ends, disc sealing surfaces, and valve seat sealing surfaces) thoroughly to remove dust and dirt.

4. The butterfly valve should be tested empty before installation. The opening and closing should be flexible.

5. Manual operation is closed clockwise and open counterclockwise. After the pointer indicates the position is not allowed to open and close the valve.

6. Tighten the bolts symmetrically and alternately, and do not allow individual tightening in sequence.

7. The limit screw has been adjusted before leaving the factory, and cannot be easily adjusted. If the drive device is configured to be electric or pneumatic, please refer to the instruction of the corresponding drive device.

8. The opening and closing stroke of the control mechanism has been adjusted when the electric butterfly valve leaves the factory. In order to prevent the direction from being wrong when the power is turned on, the user must manually open it to the half-open position before pressing the power, and then press the jog switch to check that the direction of the indicating plate is the same as the direction of the valve opening.

9. When the valve is found to be malfunctioning, the cause should be identified for repair and elimination to prevent the valve from being opened and closed by force, which will cause damage to the valve.