- Product Details

- {{item.text}}

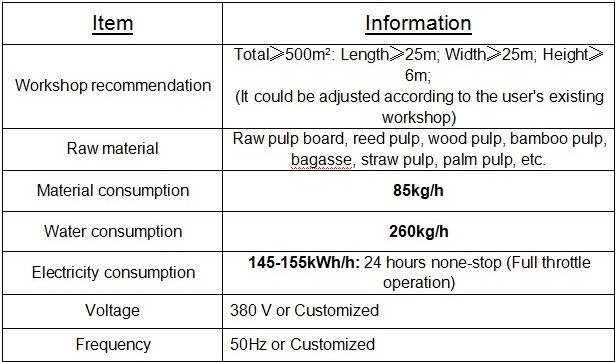

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

154KW

-

Dimension(L*W*H):

-

2105mm*1500mm*1308mm

-

Weight:

-

3500 kg

-

Name:

-

pulp biodegradable lunch box making machine production line

-

Finished Products:

-

food container/food plate/

-

Machine type:

-

automatic paper pulp food cotainer machine

-

Advantage:

-

fully automatic

-

Robot arm:

-

4-axis robot/6-axis robot

-

Pneumatic angle seat valve:

-

DN80*1set, DN40*4sets/DN25*6sets, DN15*4set

-

Molds material:

-

aluminum alloy, with stainless steel mesh

-

Vacuum pump:

-

2BEA model water-ring vacuum pump

-

Recycle pump:

-

ISW model for recycling the extra pulp and water

-

High pressure washing unit material:

-

stainless steel

Quick Details

-

Production Capacity:

-

150 pcs/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGRUN

-

Voltage:

-

380V/50HZ

-

Power:

-

154KW

-

Dimension(L*W*H):

-

2105mm*1500mm*1308mm

-

Weight:

-

3500 kg

-

Name:

-

pulp biodegradable lunch box making machine production line

-

Finished Products:

-

food container/food plate/

-

Machine type:

-

automatic paper pulp food cotainer machine

-

Advantage:

-

fully automatic

-

Robot arm:

-

4-axis robot/6-axis robot

-

Pneumatic angle seat valve:

-

DN80*1set, DN40*4sets/DN25*6sets, DN15*4set

-

Molds material:

-

aluminum alloy, with stainless steel mesh

-

Vacuum pump:

-

2BEA model water-ring vacuum pump

-

Recycle pump:

-

ISW model for recycling the extra pulp and water

-

High pressure washing unit material:

-

stainless steel

Fully automatic design, integrating the four processes of forming, drying, shaping and edge cutting

Main features: environmental protection, fully automactic with robot arms which can save labors and save cost. with high efficiency. You investiment will be back within 20 working days.

• All these three working unit were equipped with Light curtain sensor.

• Heating method: Full electric heating (electric heating power: 64kW).

• Control system: PLC + touch screen control, main electrical components adopt Siemens brand.

• Motor power: 1.5kW * 1set, heating power: 64kW

• All parts in contact with water, including slurry tanks, pipes, etc., are made of stainless steel.

• Product size range: height <80mm, thickness <1.5mm.

• Production efficiency: 19-30 seconds/die (depending on the product).

• The whole production process is automatically completed.

ELECTRIC SYSTEM

Electric cabinet

• Totally three electric cabinets, separately control pulping system, forming system, and drying & collection system;

• Including frequency converter, temperature controller, control button, contactor and relay etc. electrical components.

Operation unit

• Including one operation box which fixed in forming machine chassis, control the whole system by knobs and buttons by PLC program.

• Including air switch control button, contactor and relay etc. electrical components.

• If customer have customized requirement, this operation box can also use touch screen technology.