- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Yibo

-

Model Number:

-

YB-400

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2.1X4.5X1.9m

-

Weight:

-

3.2 KG

-

Product Name:

-

Paper Bag Machine

-

Function:

-

Making paper bag

-

Bottom Width:

-

70-260mm

-

Roll Paper Diameter:

-

1000mm

-

Paper Core:

-

76mm

-

Patch Width:

-

45-50mm

-

Power Supply:

-

380V 3Phase 38KW

-

Cutting Knife:

-

Sawtooth cutting

-

Machine Size:

-

2.1X4.5X1.9m

-

Applied material:

-

paper roll

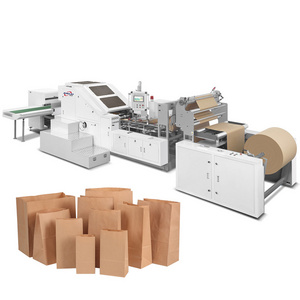

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Yibo

-

Model Number:

-

YB-400

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2.1X4.5X1.9m

-

Weight:

-

3.2 KG

-

Product Name:

-

Paper Bag Machine

-

Function:

-

Making paper bag

-

Bottom Width:

-

70-260mm

-

Roll Paper Diameter:

-

1000mm

-

Paper Core:

-

76mm

-

Patch Width:

-

45-50mm

-

Power Supply:

-

380V 3Phase 38KW

-

Cutting Knife:

-

Sawtooth cutting

-

Machine Size:

-

2.1X4.5X1.9m

-

Applied material:

-

paper roll

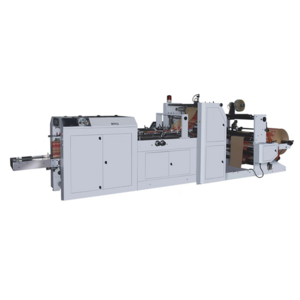

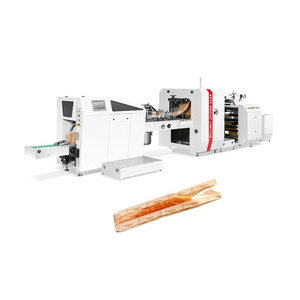

Product Overview

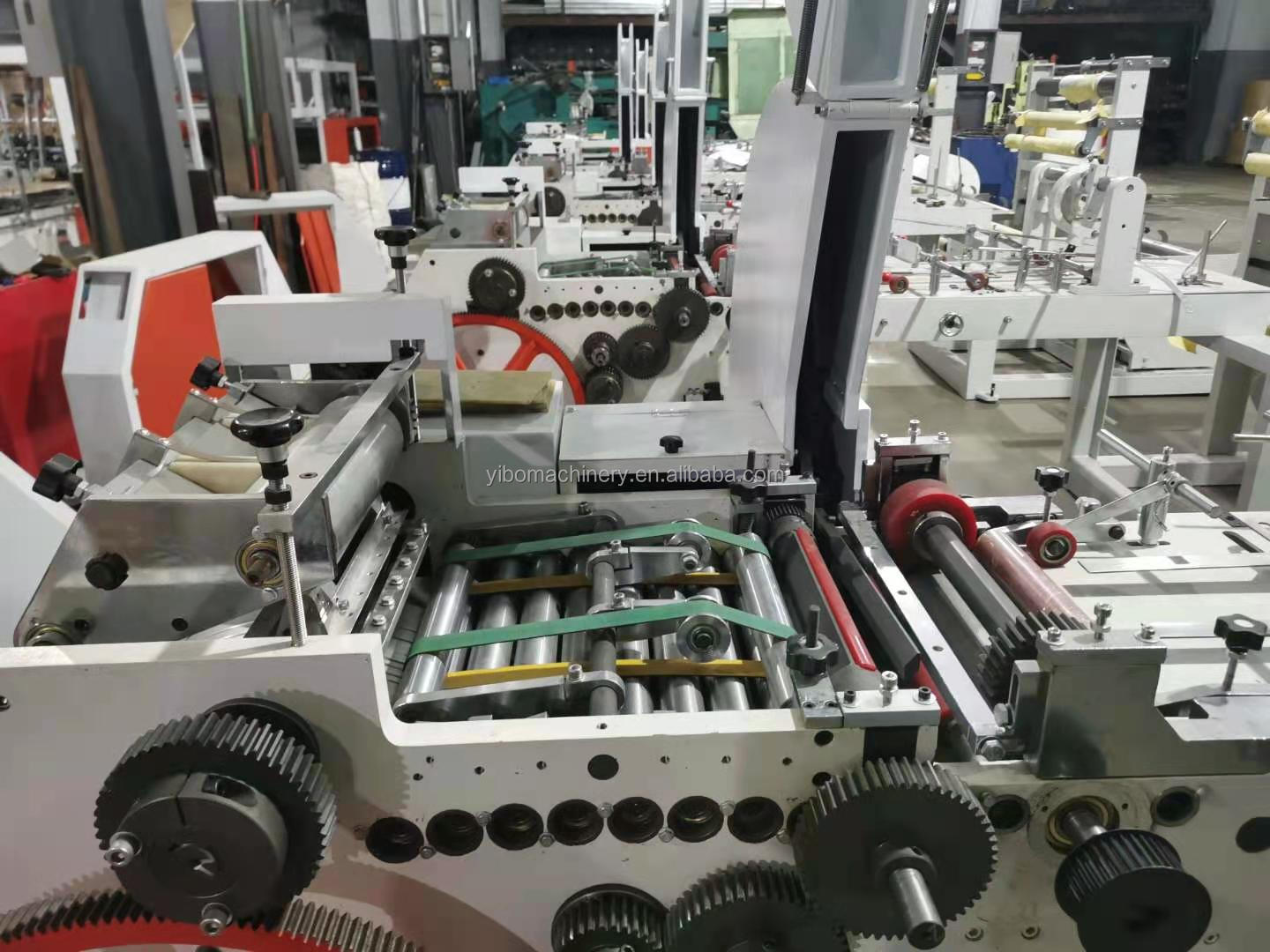

YB-400&600 Automatic Paper Bag Making Machine

Configuration

1. Adopt touch screen and PLC programmable control system, the work condition can be shown real time. Cooperate with the ultra

precise double servo motor, the stability can be guaranteed.

2. The machine has automatic counting system. The user can set a number to count. When bag quantity meets the number, the bag

will be jumped out like the picture shows.

3. Adjustable bottom gluing system makes the adjustment of different gluing specification very easy.

4. Lower glue tank structure can use the glue directly. The glue doesn’t need glue thickener to increase viscosity. The structure

can improve efficiently the phenomenon that the high viscosity glue makes bag bottom fold. The gluing will be evener. Solve the

problem that the upper glue tank structure leaks glue when the machine run with slow speed.

5. Cutter positioning structure makes the cutter dismounting very easy. Installation of cutter does not need complicated

adjustment.

6. Cutter safety shield protection switch can avoid the danger that user forgets to close the shield when machine runs with high

speed.

7. The paper tube forming system can be adjusted as a whole. It can increase the work efficiency and stability; reduce the waster

rate during the producing; and save time of adjusting.

8. Width adjustable folding wheel can save a lot of time and cost which is used to make the arc plate, avoid complicated changing

procedure of arc plate.

9. Precise color mark tracing system can make sure precision of bag printing pattern cutting position. The color mark tracing

function can avoid the readjustment after paper reel changing, paper web breaking, or power outage. The machine can stop

automatically when the color mark is error. It will save time and reduce the waster rate.

10. Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. The motor doesn’t need to work

often so its power consumption is reduced and its life is extended. (User can choose single photoelectric sensor to control edge.)

Configuration

1. Adopt touch screen and PLC programmable control system, the work condition can be shown real time. Cooperate with the ultra

precise double servo motor, the stability can be guaranteed.

2. The machine has automatic counting system. The user can set a number to count. When bag quantity meets the number, the bag

will be jumped out like the picture shows.

3. Adjustable bottom gluing system makes the adjustment of different gluing specification very easy.

4. Lower glue tank structure can use the glue directly. The glue doesn’t need glue thickener to increase viscosity. The structure

can improve efficiently the phenomenon that the high viscosity glue makes bag bottom fold. The gluing will be evener. Solve the

problem that the upper glue tank structure leaks glue when the machine run with slow speed.

5. Cutter positioning structure makes the cutter dismounting very easy. Installation of cutter does not need complicated

adjustment.

6. Cutter safety shield protection switch can avoid the danger that user forgets to close the shield when machine runs with high

speed.

7. The paper tube forming system can be adjusted as a whole. It can increase the work efficiency and stability; reduce the waster

rate during the producing; and save time of adjusting.

8. Width adjustable folding wheel can save a lot of time and cost which is used to make the arc plate, avoid complicated changing

procedure of arc plate.

9. Precise color mark tracing system can make sure precision of bag printing pattern cutting position. The color mark tracing

function can avoid the readjustment after paper reel changing, paper web breaking, or power outage. The machine can stop

automatically when the color mark is error. It will save time and reduce the waster rate.

10. Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. The motor doesn’t need to work

often so its power consumption is reduced and its life is extended. (User can choose single photoelectric sensor to control edge.)

|

Model

|

YB—400

|

YB—650

|

|

Cutting length

|

270-500mm

|

270-500mm

|

|

|

270-410mm(Whole)

|

270-410mm(Whole)

|

|

Bag width

|

150-330mm

|

260-450mm

|

|

|

200-330mm(Whole)

|

260-450mm(Whole)

|

|

Bottom width

|

60-180mm

|

80-180mm

|

|

Paper Thickness

|

60-150g/㎡

|

80-150g/㎡

|

|

|

80-150g/㎡(Whole)

|

80-150g/㎡(Whole)

|

|

Paper roll width

|

380-1050mm

|

700-1300mn

|

|

|

620-1050mm(Whole)

|

710-1300mm(Whole)

|

Production Process

Certifications

Sample Room

Partners

Packaging&Shipping

Hot Searches