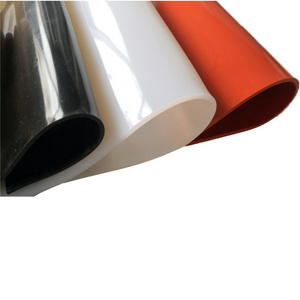

Liquid silicone for breast pads Features and Applications.

Liquid silicone for doll simulation has low hardness, high tear resistance and high human texture simulation.

It is suitable for the production of human organs, adult sexual products and human simulations, and its low viscosity can be used in the injection molding process.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Mold Making Materials

-

Product name:

-

Raw Material Silicone Rubber

Quick Details

-

Place of Origin:

-

Huizhou

-

Brand Name:

-

Jiajing Hong Silicone

-

Model Number:

-

600

-

Application:

-

Mold Making Materials

-

Product name:

-

Raw Material Silicone Rubber

Products Description

Human Silicone

Product Usage

*

How to use liquid silicone for chest pads:

Mix A and B components according to 1:0.95-1.05, after vacuum defoaming, you can pour, the operation time depends on the temperature (0.5-3)H, vulcanization time (room temperature) 12-24H, heating 80-120°C can be vulcanized within tens of minutes. The room temperature fast drying type has an operating time of less than 20 minutes and a vulcanisation time of 1 hour. Other colours such as red and yellow can be matched according to user requirements.

Precautions for breast pad silicone:

This silicone should not come into contact with any other condensed silicone, otherwise it will cause poisoning of the curing agent and cause the silicone not to cure. Water, impurities, organic tin catalysts, acids, alkalis and other organic substances containing sulphur, phosphorus and nitrogen can affect the curing of the rubber, so do not mix or contact these substances when using.

Product Features

Product Paramenters

|

Model

|

H803c

|

H805c

|

H810c

|

H820c

|

H802

|

H805

|

H810

|

H815

|

|

Appearance

|

Translucent

|

Translucent

|

Translucent

|

Translucent

|

Translucent

|

Translucent

|

Translucent

|

Translucent

|

|

Hardness (Shore Aº)

|

0±0

|

0±0

|

0±1

|

0±2

|

2±2

|

5±2

|

10±2

|

15±2

|

|

Mixing weight ratio of two components (A: B)

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

|

Dynamic viscosity (mPa.s)

|

4000±1000

|

40000±1000

|

40000±1000

|

5000±1000

|

5000±1000

|

5000±1000

|

5000±1000

|

5000±1000

|

|

Tensile strength (MPa)

|

4

|

4

|

5

|

5.3

|

6.2

|

6.2

|

6.3

|

6.3

|

|

Tear strength(kN/m)

|

8±2

|

8±2

|

8±2

|

12±2

|

14±2

|

16±2

|

18±2

|

20±2

|

|

Elongation (%)

|

430

|

430

|

430

|

460

|

460

|

480

|

510

|

520

|

|

Density(g/cm)

|

0.9

|

0.9

|

0.9

|

0.9

|

1.0

|

1.0

|

1.05

|

1.05

|

|

Operation time(min)

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

|

Vulcanization time (h)

|

4-6

|

4-6

|

4-6

|

4-6

|

4-6

|

4-6

|

4-6

|

4-6

|

|

Line shrinkage not rate (%)

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

Product packaging

Hot Searches