- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chengda

-

Outer Diameter:

-

4 - 2420 mm

-

Thickness:

-

4mm-70mm

-

Grade:

-

Q345 Q355B GR.50 S355J/ST52 EN14

-

MOQ:

-

1 Ton

-

Technology:

-

Hot Rolled Seamless

-

Material:

-

Q345 Q355B GR.50 S355J/ST52 EN14

-

Packing:

-

Standard Seaworthy Packing

-

Type:

-

seamless steel pipe

-

OD:

-

2mm - 2420mm

-

Technique:

-

Hot Rolled Cold Rolled

-

Wall Thickness:

-

4mm-70mm

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chengda

-

Outer Diameter:

-

4 - 2420 mm

-

Thickness:

-

4mm-70mm

-

Grade:

-

Q345 Q355B GR.50 S355J/ST52 EN14

-

MOQ:

-

1 Ton

-

Technology:

-

Hot Rolled Seamless

-

Material:

-

Q345 Q355B GR.50 S355J/ST52 EN14

-

Packing:

-

Standard Seaworthy Packing

-

Type:

-

seamless steel pipe

-

OD:

-

2mm - 2420mm

-

Technique:

-

Hot Rolled Cold Rolled

-

Wall Thickness:

-

4mm-70mm

Products Description

|

Description of seamless steel pipe by Chengda steel

|

|

|

|

Product Name

|

Hot sale A192 ST33 DIN 1626 carbon seamless steel pipe

|

|

|

Standard

|

API,ASME, ASTM, EN ,BS,GB,DIN, JIS,AISI,SAE

|

|

|

Outer Dia:

|

4mm-2420mm

|

|

|

Wall Thickness

|

4mm-70mm

|

|

|

Shape

|

round

|

|

|

Materials

|

A192 ST33 DIN 1626

|

|

|

Inspection

|

ISO,BV,SGS,MTC

|

|

|

Packing

|

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit forall kinds of transport,or as required

|

|

|

Supply Ability

|

20000 tons/month

|

|

|

MOQ

|

1metric ton,sample order accepted

|

|

|

Shipment time

|

3-15days and Depend on Customer&primes Order

|

|

|

Payments

|

T/T,L/C

|

|

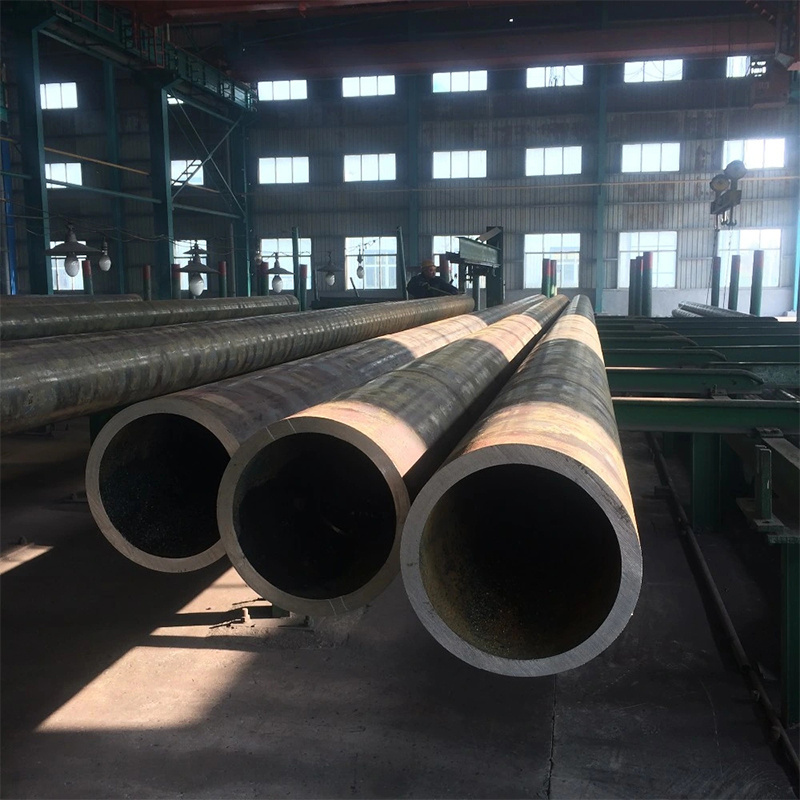

Products Photos

Product introduction

The raw material of the carbon steel pipe is the round tube blank. The round tube blank is cut by the cutting machine to process the blank with a length of about 1m, and is sent to the furnace through the conveyor belt for heating. The billet is heated in the furnace at a temperature of about 1200 degrees Celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key problem After the round tube billet is discharged from the furnace, it shall be pierced through the pressure piercer.

Generally, the more common piercer is the cone-shaped roller piercer. This piercer has high production efficiency, good product quality, large perforation expansion and can wear a variety of steel grades. After piercing, the round tube billet is successively cross rolled, continuous rolled or extruded by three rolls. After extrusion, the pipe shall be removed for sizing. The sizing machine uses the conical drill to rotate into the steel blank at high speed to form the steel pipe. The inner diameter of the steel pipe is determined by the outer diameter length of the drill bit of the sizing machine. After sizing, the steel pipe enters the cooling tower and is cooled by spraying water. After cooling, the steel pipe is straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by the conveyor belt for internal flaw detection. If there are cracks, bubbles and other problems inside the steel pipe, they will be detected. After quality inspection, steel pipes shall be selected strictly by hand. After quality inspection, the steel pipe shall be painted with number, specification, production batch number, etc. And hoisted into the warehouse by crane.

Generally, the more common piercer is the cone-shaped roller piercer. This piercer has high production efficiency, good product quality, large perforation expansion and can wear a variety of steel grades. After piercing, the round tube billet is successively cross rolled, continuous rolled or extruded by three rolls. After extrusion, the pipe shall be removed for sizing. The sizing machine uses the conical drill to rotate into the steel blank at high speed to form the steel pipe. The inner diameter of the steel pipe is determined by the outer diameter length of the drill bit of the sizing machine. After sizing, the steel pipe enters the cooling tower and is cooled by spraying water. After cooling, the steel pipe is straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by the conveyor belt for internal flaw detection. If there are cracks, bubbles and other problems inside the steel pipe, they will be detected. After quality inspection, steel pipes shall be selected strictly by hand. After quality inspection, the steel pipe shall be painted with number, specification, production batch number, etc. And hoisted into the warehouse by crane.

Product processing

Certifications

Packaging & transportation

Hot Searches