It,s the first step of Breakfast cereals/Corn Flakes production line

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

39000x1200x2200mm

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

440V

-

Power:

-

38-500kw

-

Name:

-

Corn flakes Breakfast cereals Making Machine

-

Application:

-

Corn flakes Breakfast cereals

-

Raw material:

-

wheat corn flour

-

Usage:

-

Supermarket

-

Production Capacity:

-

120kgh, 180kgh, 300kgh

-

Consumption:

-

Low electricity and labor consumption

-

Specification:

-

Stainless steel

-

Type:

-

Twin Screw Extruder

-

Brand:

-

Benro

-

Power Source:

-

Eletric Gas

Quick Details

-

Machinery Capacity:

-

150-1000

-

Brand Name:

-

Benro

-

Year:

-

2024

-

Dimension(L*W*H):

-

39000x1200x2200mm

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

440V

-

Power:

-

38-500kw

-

Name:

-

Corn flakes Breakfast cereals Making Machine

-

Application:

-

Corn flakes Breakfast cereals

-

Raw material:

-

wheat corn flour

-

Usage:

-

Supermarket

-

Production Capacity:

-

120kgh, 180kgh, 300kgh

-

Consumption:

-

Low electricity and labor consumption

-

Specification:

-

Stainless steel

-

Type:

-

Twin Screw Extruder

-

Brand:

-

Benro

-

Power Source:

-

Eletric Gas

Product Description

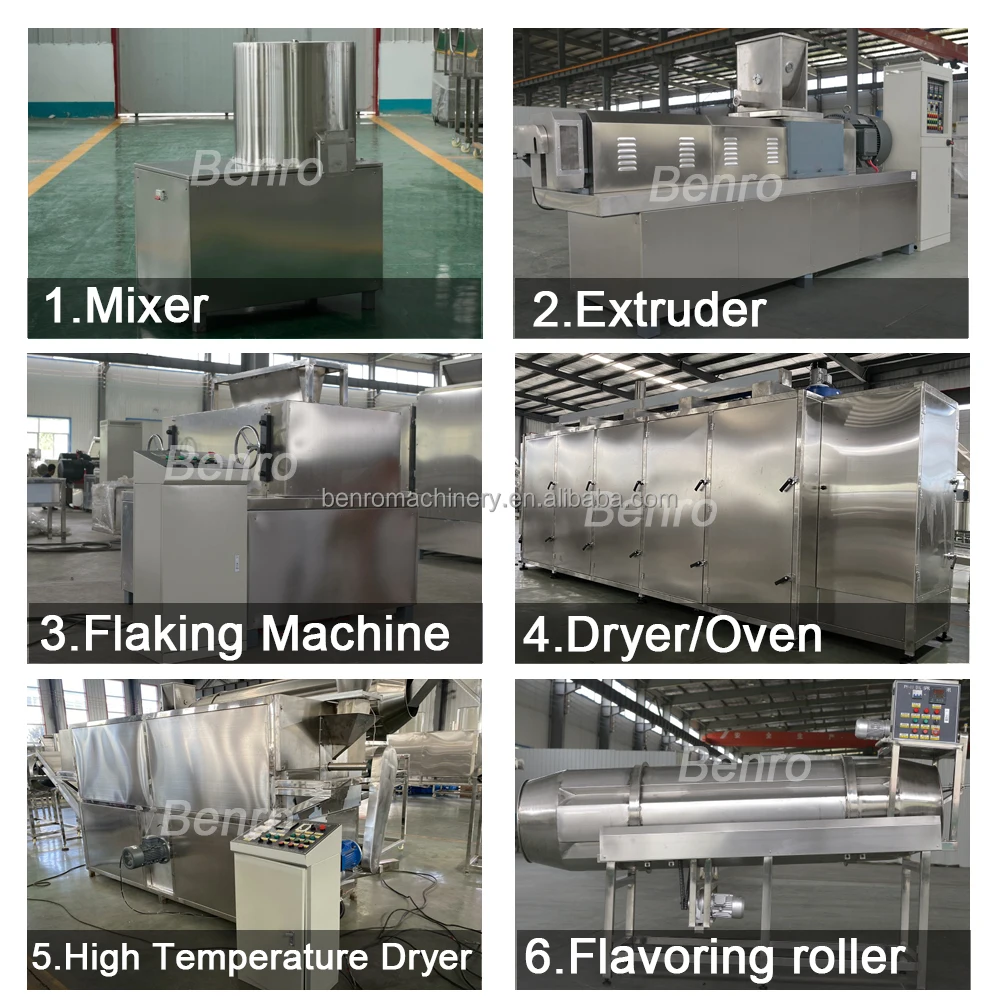

Mixer---Screw conveyor---Extruder---Vibrate cooler---Air conveyor---Flaking machine---Air conveyor---Dryer---Air convey---Roller dryer---Hoister---Flavor roller---Hoister---Dryer---Cooling machine---Melting machine---Sugar sprayer--Air compressor

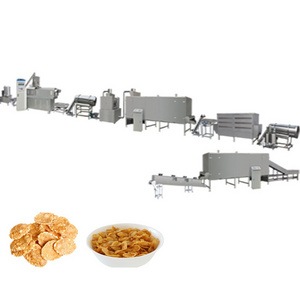

Introduction Corn Flakes/Breakfast Cereals Machine

Corn Flakes/Breakfast Cereals are a kind of breakfast with high nutritional value.They usually use corn powder and other cereals as main raw material,through mixing,extruding,flaking,drying,baking,coating and cooling,to get crispy flakes.It always service as breakfast cereal mixed with milk or coffee.But it can also be a kind of leisure snacks.This process line can also make other shapes of cereals suah as rings,balls,chocos,curls etc.

1) Raw materials:

Corn flour, rice flour, wheat flour, soya flour, millet flour, corn grits, and other different grain flours.

2) Final food : Different shapes and sizes of Corn flakes,Breakfast cereals

3) Capacity: 120-150kg/h, 180-200kg/h, 300kg/h...

4) Consumption: Low electricity and labor consumption

5) Design: With flexible design based on the client's demands, we provide turn key project.

Specification

|

Model

|

Installed power

|

Power consumption

|

Output

|

Size

|

|

SLG65

|

140kw

|

90kw

|

120-150kg/h

|

39000x1200x2200mm

|

|

SLG70

|

160kw

|

120kw

|

180-200kg/h

|

41000x1500x2200mm

|

|

SLG85

|

190kw

|

140kw

|

300kg/h

|

43000x3500x4300mm

|

Details Images

Mixer

This machine can mix raw material(Corn flour, rice flour, wheat flour, soya flour, millet flour, corn grits.....),water and other additives.

Twin screw extruder

1.Specially decide twin-screw system extruder and form the raw material into different sizes and shapes of Bugle chips, Breakfast cereals.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting system,lubricating system.

Flaking Machine

In addition to breakfast cereals, you need to add this machine to produce cornflakes.

The Corn Flaking machine is composed of a pair of alloy steel roller srotating in opposite directions,a high strength frame,a manual roll gap adjusting system,a roll cooling constant temperature system,a transmission system and a control system.(With Cooling system,new designed)

Oven/Dryer

The mode of running of this machine internal is back and forth movement of the stainless steel mesh wire. It not only improves intake capacity of material, reduces floor area, but also equally arranges material,improve the material drying rate. This dryer has the hot air circuiting device, the food is dried evenly, and save the gas energy. The moisture inside of breakfast cereals is about 20% after extruder. It needs suitable drying temperature and time to reduce moisture below 10%.

There are stainless steel baffles at both side of belt to prevent material fall down from belt.

High-temperature Roller dryer

1. Machine material is stainless steel food grade

2. There are Rotary drum inside.

3. The heating way are electric type.

4. The temperature is very high,more than 200 degree.

5. It can help the corn flakes expand very well.

Flavoring roller

1.It includes flavor tank, flavor sprayer and rotary roller.

2.Slope of the roller with folded wing can be adjusted to ensure flavor onto the surface evenly,thus can increase flavorful taste.

3.All the rotary roller adopts stainless steel, and the rolling speed can be adjusted.

Packing & Delivery

Hot Searches