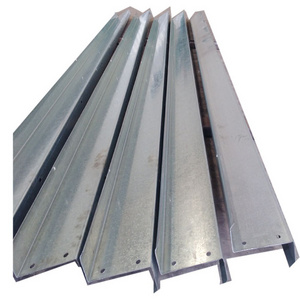

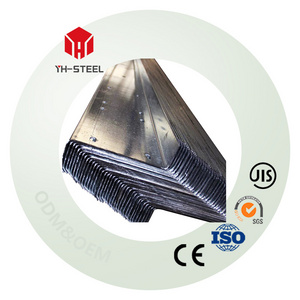

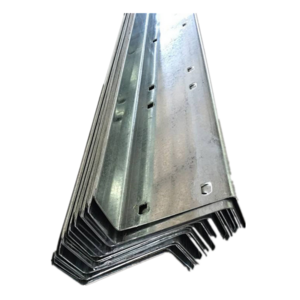

-No side drilling/cutting required

-Assured dimensions and straightness

-Purlin erection is easier than others

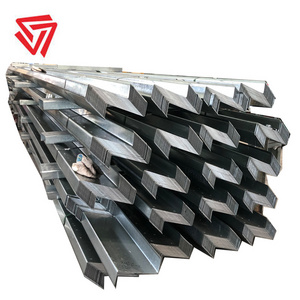

-Saving in construction cost up to 30%

-High durability,versatility and uniform quality

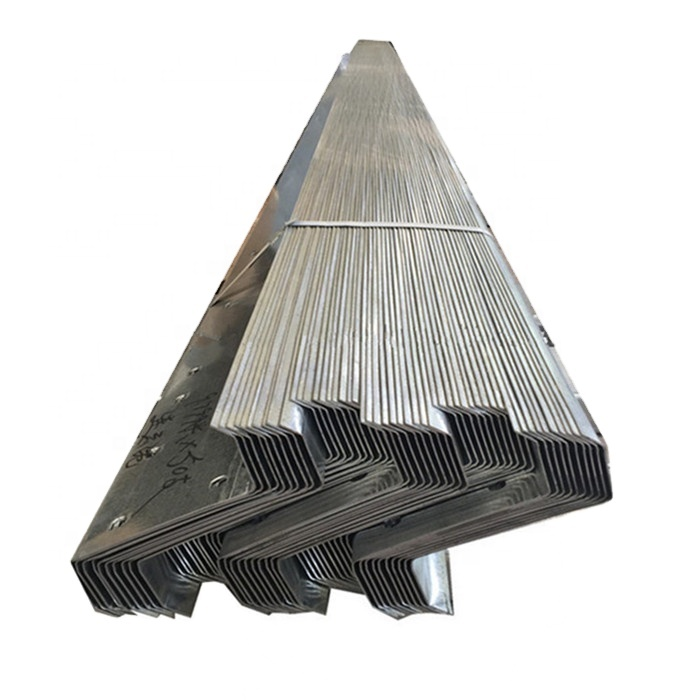

-Low transportation cost due to reduced weight

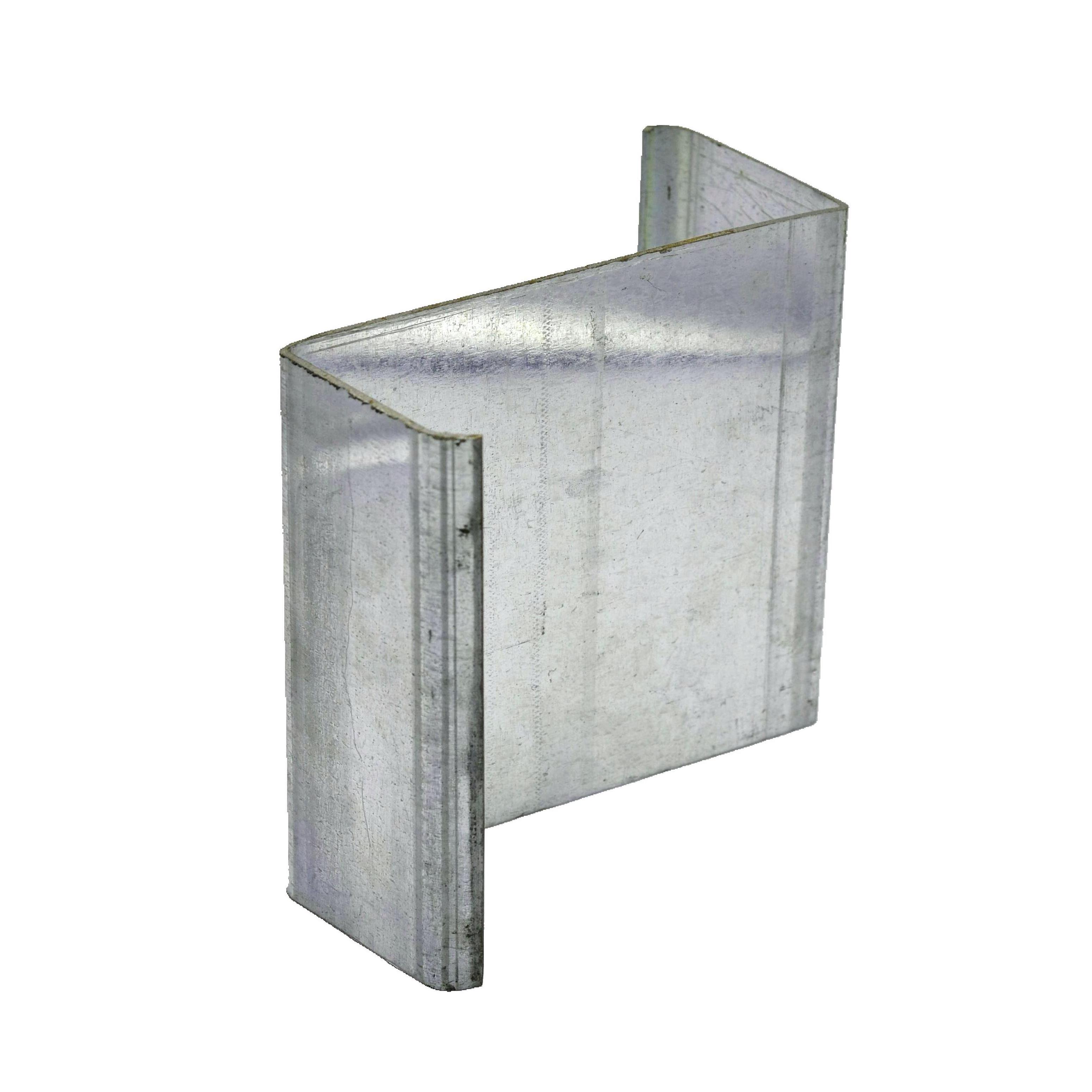

-Close tolerances on

sectional

dimensions owing to the process of cold roll forming

-Saving up to 35-40% in weight and 20% in cost when compared to hot rolled purlins