- Product Details

- {{item.text}}

Quick Details

-

Tooth Material:

-

PDC cutter or Alloy

-

Heat treatment:

-

HRC 42-46

-

Net weight:

-

1.5KG

-

Full Height:

-

130-152mm

-

Application:

-

Ore mining

-

Advantage:

-

High impact and wear resistance

-

Raw material:

-

4140 Alloy steel

-

Mounting Product:

-

Cold forged alloy pocket

-

Package:

-

Wooden Case

Quick Details

-

Place of Origin:

-

Changge City China

-

Brand Name:

-

HUANGHE WHIRLWIND

-

Body:

-

Steel or Matrix

-

Tooth Material:

-

PDC cutter or Alloy

-

Heat treatment:

-

HRC 42-46

-

Net weight:

-

1.5KG

-

Full Height:

-

130-152mm

-

Application:

-

Ore mining

-

Advantage:

-

High impact and wear resistance

-

Raw material:

-

4140 Alloy steel

-

Mounting Product:

-

Cold forged alloy pocket

-

Package:

-

Wooden Case

Based on 40 years Group company manufacturing experience

Huanghe whirlwind superhard composite material Division start the business of round shank picks from 2017.The project was established in 2017 and is positioned to apply 3D printing technology, powder metallurgy technology and superhard composite material technology to the hard surface treatment of products, improve wear resistance and extend service life.The main picks series is rotary drill picks,road header picks,coal mining picks and road milling picks.

Factory price,integrating production

Huanghe whirlwind co., ltd superhard composite material division manufactures wide range of round shank pick, including rotary drilling picks,road header picks,coal mining picks. Taking advantage of the best raw material, advanced welding technology, advanced heat treatment process and structural design, which have a faster drilling speed and longer service life.

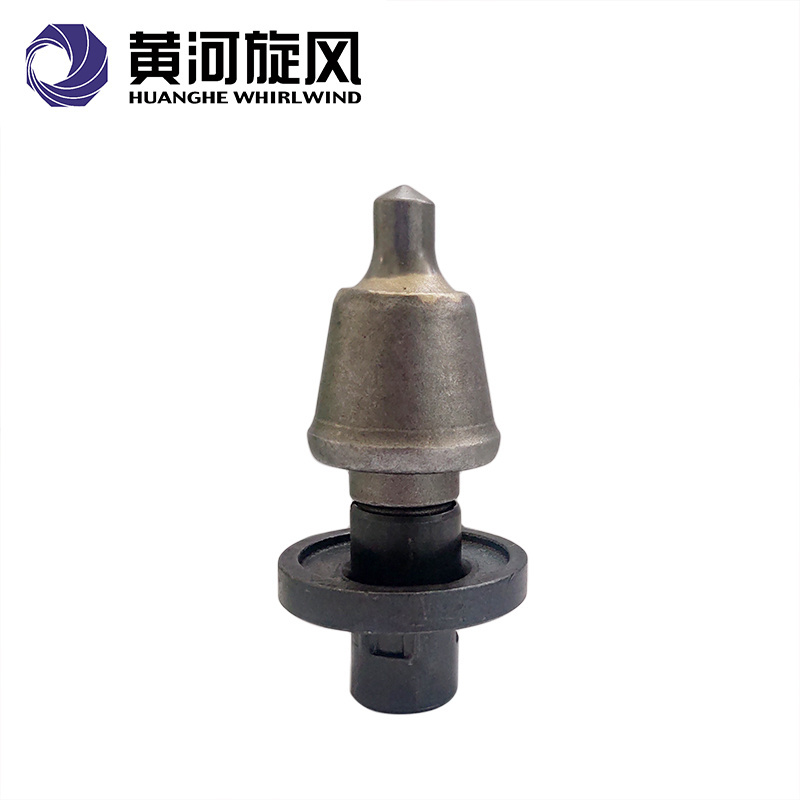

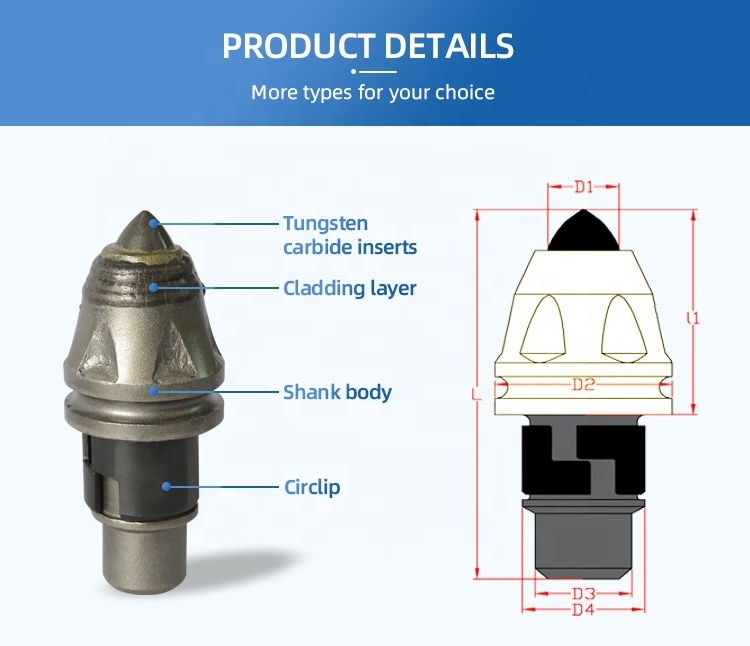

Tungsten carbide inserts

Use large-grain coarse-grained tungsten carbide, which has high wear resistance, impact resistance and thermal stability

Shank body

High-quality alloy steel is selected, and the stable heat treatment process makes the tooth body wear-resistant and tough

Brazing process

Through special welding process, the strength of pick welding is increased, the impact resistance is improved, and the carbide tip is not easy to fall off

Shank reinforcement

Through laser cladding, powder metallurgy technology and other technologies to protect the head of the tooth body, reduce the wear rate and extend the service life

| (mm) | ||||||||

| Model |

Carbide diameter (D1) |

Body diameter (D2) |

Clip daimeter (D3) |

Clip width | Clip location | Holder length | Body length | Type |

| HWGX3050 | 16-22 | 50 | 30 | 38 | / | 70-90 | 130-150 | Rotary picks |

| HWGX3055 | 19-30 | 55 | 30 | 38 | / | 75 | 135 | Rotary picks |

| HWGX3060 | 19-30 | 60 | 30 | 38 | / | 73-92 | 133-152 | Rotary picks |

| HWMC U84 | 16-22 | 30 | 26 | 28 | 65.5 | 80 | 152 | Coal picks |

| HWMC U92 | 16-22 | 35 | 30 | 28 | 82 | 102 | 196 | Coal picks |

| HWMC U94 | 19-25 | 35 | 30 | 28 | 82 | 90 | 184 | Coal picks |

| HWMC U95 | 22-30 | 35 | 30 | 28 | 82 | 90 | 184 | Coal picks |

| HWMCU170 | 22-30 | 43 | 35 | 30 | 28 | 112 | 102 | Coal picks |

| HWMJS135 | 19-30 | 38 | 35 | 5 | 70 | 80 | 80 | Road header picks |

| HWMCU47 | 16-25 | 38 | 30 | 26 | 7 | 70.5 | 71 | Road header picks |

Acco r ding to different applications , HHW offers three major types round shank picks : rotary drilling picks,road header picks,road milling picks.Mainly used for coal mining and tunnel,tunnels,ground trenching and other excavation works, and mainly equipped with shearer,boring machine,milling machines and other equipment. Applied to all kinds of soft and hard soil, rock and concrete layer.

How can we keep the quality stable?

1. Raw material selected

2. Advanced design and production equipment

3. Skilled technician

4. Finished Product testing

5. Customers ’ feedback to change design and materialas