- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

380V/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Dimension(L*W*H):

-

2450*1900*2400mm

-

Weight:

-

3500 KG

-

Function:

-

Filling & Sealing

-

Material of structure:

-

SUS304/316

-

Filling material:

-

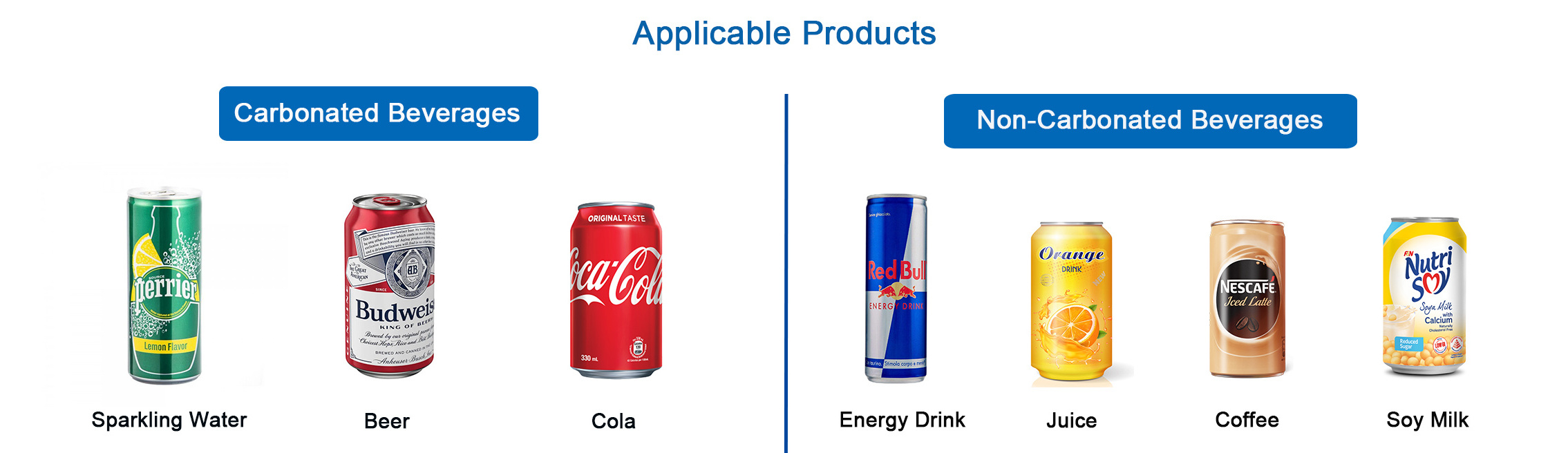

Carbonated Beverage / Juice

-

Capacity(500ml):

-

2000-12000BPH

-

Bottle type:

-

Pop can / Aluminum can / Tin can

-

Filling volume:

-

200-1000ml

-

Processing Types:

-

Filling and Sealing

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 6000BPH, 500BPH, 2000BPH

-

Packaging Material:

-

Glass

-

Filling Material:

-

Beer, Juice, Carbonated Beverage

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

380V/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Dimension(L*W*H):

-

2450*1900*2400mm

-

Weight:

-

3500 KG

-

Function:

-

Filling & Sealing

-

Material of structure:

-

SUS304/316

-

Filling material:

-

Carbonated Beverage / Juice

-

Capacity(500ml):

-

2000-12000BPH

-

Bottle type:

-

Pop can / Aluminum can / Tin can

-

Filling volume:

-

200-1000ml

-

Processing Types:

-

Filling and Sealing

Product Description

Easy To Operate Carbonated Beverage beer can filler canning machines for sale

We provide the complete Can filling and package solution ,from can depalletizer ,can rinsing machine ,can filling & sealing monoblock machine ,leakage check,liquid nitrogen dosing machine ,pasteurizer tunnel ,blow dryer ,carton package ,film package system ,which is widely used for the beverage ,beer ,Juice industry and so on.

We provide the complete Can filling and package solution ,from can depalletizer ,can rinsing machine ,can filling & sealing monoblock machine ,leakage check,liquid nitrogen dosing machine ,pasteurizer tunnel ,blow dryer ,carton package ,film package system ,which is widely used for the beverage ,beer ,Juice industry and so on.

Technical Parameters:

|

Model

|

GF12-1

|

GF18-6

|

GF24-6

|

GF32-8

|

GF40-10

|

||||

|

Capacity (310ml)

|

2000

|

5000

|

7000

|

10000

|

12000

|

||||

|

Application

|

Beer, carbonated drinks, cold coffee, sparkling water, cider, soda water, herbal tea, non-carbonated drinks etc

|

|

|

|

|

||||

|

Packing Material

|

Aluminum cans,Tin cans,PET cans etc

|

|

|

|

|

||||

|

Filling Range

|

130ml, 250ml, 330ml, 355ml, 500ml, 12oz, 16oz, 1L and so on (0.1-1L)

|

|

|

|

|

||||

|

Filling type

|

Isobaric filling / Normal pressure filling

|

|

|

|

|

||||

|

Power (Kw)

|

0.75

|

3.7

|

3.7

|

4.2

|

6.5

|

||||

|

Diamension (M)

|

1.8*1.3*2.3

|

2.3*1.4*2.3

|

2.58*1.7*1.9

|

2.8*1.7*1.95

|

4.8*2.3*2.5

|

||||

|

Weight (Kg)

|

1800

|

2500

|

3000

|

3800

|

5000

|

||||

Product Display

Can Filling Sealing Machine

The machine is advanced filling and sealing equipment, it’s designed on the basis of absorbing domestic and foreign advanced technology. It is mainly used in filling and sealing carbonated beverages like soft drinks, cola, sparkling wine, etc. It has such advantages as advanced construction, stable working, convenient operation, and repair & maintenance, transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the isobaric pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink , cold brew coffee, herbal tea and so on.

Can Depalletizer

Put the pallet on the plate, and push to the net conveyors from upper to downside. Then conveyors will transport empty can to the washing machine. Instead of manpower place can, it saves a lot of workers.

Can Rinser

Function : washing can inside and outside dust . All 304/316stainless steel rinse heads, water spray style inject design, more

save water consumption and more clean.

save water consumption and more clean.

Advantages of Our Glass Bottle Filling Machine

1) The overall appearance is comfortable, and the window-type structure can be used to keep an eye on the movement of the machine.

If there is a problem, the machine can be stopped and checked in time.

2) PLC controller, simple and easy to operate, designed for foreign friends, allowing customers to easily navigate.

3) The whole machine material is made of stainless steel 304/316, which is very strong and guarantees the quality.

4) High filling accuracy and small error, ensuring efficiency while ensuring efficiency.

5)Three-in-one filling, the finished product is short.

6) Fully automatic production, freeing hands, reducing labor required for production, saving costs and improving efficiency .

Details of Our Glass Bottle Filling Machine

1) The overall appearance is comfortable, and the window-type structure can be used to keep an eye on the movement of the machine.

If there is a problem, the machine can be stopped and checked in time.

2) PLC controller, simple and easy to operate, designed for foreign friends, allowing customers to easily navigate.

3) The whole machine material is made of stainless steel 304/316, which is very strong and guarantees the quality.

4) High filling accuracy and small error, ensuring efficiency while ensuring efficiency.

5)Three-in-one filling, the finished product is short.

6) Fully automatic production, freeing hands, reducing labor required for production, saving costs and improving efficiency .

Details of Our Glass Bottle Filling Machine

1.How to tell us your enquiry?

You can contact us by email, phone call, fax, Instant Messenger (Trademanager,WhatsApp,Skype) and let us know your requirement.

2.Are you manufacturer or trading company ?

We are industrial manufacturer, which locates in Zhangjiagang city over 18 years

3.Where is your factory?

Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi(airplame and train both available). lf you arrive at Shanghai or Wuxi, we can pickyou up to visit our factory.

4. Do you have any technical supports with your Beverage FillingMachines?

Yes, We have a professional team of engineers who owned many installation,debug and training experiences abroad, are available to service machinery over-seas.

Hot Searches