- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

QDZD

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2250*850*1040mm

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

15.57

-

Product Name:

-

Wood Planer Machine

-

Function:

-

Woodworking Planing

-

Keywords:

-

Thicknesser Planer Machinery

-

Feeding speed:

-

5-20m/min

-

Motor power:

-

15.57KW

-

Max working width:

-

150mm

-

Max cutting depth:

-

125mm

-

Spindle rotation speed:

-

6000r/min

-

Color:

-

Customer Requirment

-

Net weight:

-

1500kg

Quick Details

-

Max.Planing Depth(mm):

-

125 mm

-

Max.Planing Width(mm):

-

300

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

China

-

Brand Name:

-

QDZD

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2250*850*1040mm

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

15.57

-

Product Name:

-

Wood Planer Machine

-

Function:

-

Woodworking Planing

-

Keywords:

-

Thicknesser Planer Machinery

-

Feeding speed:

-

5-20m/min

-

Motor power:

-

15.57KW

-

Max working width:

-

150mm

-

Max cutting depth:

-

125mm

-

Spindle rotation speed:

-

6000r/min

-

Color:

-

Customer Requirment

-

Net weight:

-

1500kg

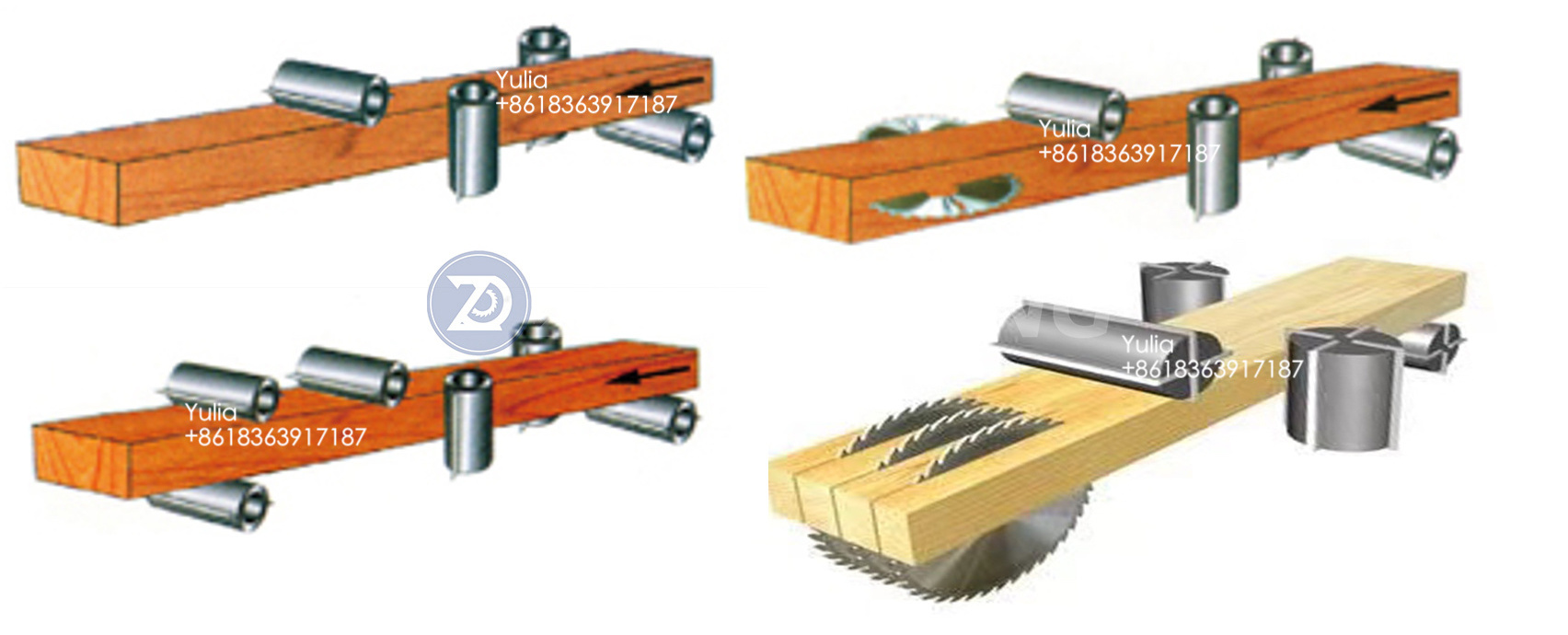

Wood Thickness Planer Machine Four-sided Planer Machine

Four sided planer consist of top, bottom and side cutter heads that allows timber to be planed or moulded on all four sides

(depending on the model). A table is mounted on a elongated machine frame. The machine frame is equipped with motors to drive the

spindles. In most cases four side planers are assembled with four spindles, which are arranged below, right, left and above the

table. The workpiece passes the with cutter heads tipped spindles via toothed wheels.

(depending on the model). A table is mounted on a elongated machine frame. The machine frame is equipped with motors to drive the

spindles. In most cases four side planers are assembled with four spindles, which are arranged below, right, left and above the

table. The workpiece passes the with cutter heads tipped spindles via toothed wheels.

Customization

We Value the needs of every customer ,and each project tailors the most cost-effective solution . According to your requirements of the wood products ,we can provide customized models with different solutions , we aim to supply a one-stop solution for the furniture workshop, provide customization service for you!For four sided planer ,we can supply with multi-blade saw modules (horizontal and vertical orientation) and different number of cutter shafts (4~6). The machine can be equipped with a silent and dust-proof chamber.

Customization of flat cutter, discarded spiral cutter, milling cutter and other different cutter.

Customization of flat cutter, discarded spiral cutter, milling cutter and other different cutter.

Details

1..Heavy duty body structure, not easy to deform, to ensure long-term stability

2. All the spindle is with seperated motors ,makes the cutting strong.

3. Feeding Speed 7-28m/min,improve the production efficiency greatly. 4. Feeding wheel,using cylinder compression type,can be individual adjusted to its pressure,which makes feeding more smoothly.

5. High speed spindle equipped with SKF high-speed bearings, more smooth cutting,SCHNEIDER electric system, pure copper motor.

6. All the parts are made with fine processing of high-precision CNC Center ,and this ensures stable and efficient operation

Easy operating control panel,imported electric control system ,stable and reliable ,provide with multiple safety protection device.It can control the feeding wheel up and down, forward and reverse. Start/stop of each spindle ,and emergency stop .

aluminum strip, so that the wood enters parallel to the knife axis and does not tilt.

security.

electrics safety .

facilitate the production of wood of different sizes.

Application

Four side moulder/planer is mainly used for processing wood products such as wooden squares, planks, decorative moldings, wooden

floors, etc., and planing the upper, lower and side surfaces of the wood.

|

Model

|

MB4015GX

|

MB4023DR

|

MB4030DR

|

|

|

Minimum planing length (continuous feeding)

|

550mm

|

550mm

|

550mm

|

|

|

Maximum planing width

|

150mm

tool outer diameter of 100mm |

230mm

tool outer diameter of 120mm |

300mm

tool outer diameter of 120mm |

|

|

Minimum planing width

|

20mm

|

20mm

|

40mm

|

|

|

Maximum planing thickness

|

120mm

|

150mm

|

200mm

|

|

|

Minimum plane thickness

|

8mm

|

8mm

|

10mm

|

|

|

The maximum lifting range of the front workbench

|

5mm

|

5mm

|

5mm

|

|

|

Maximum movement amount of the front workbench guide panel

|

5mm

|

5mm

|

5mm

|

|

|

The diameter

|

∅120mm

|

∅140mm

|

∅140mm

|

|

|

Feed delivery speed

|

5-30m/min

|

5-30m/min

|

5-20m/min

|

|

|

Tool shaft speed

|

6000r/min

|

6000r/min

|

6000r/min

|

|

|

Axial movement amount of the knife shaft

|

|

|

|

|

|

The front and lower knife axle moves around by

|

10mm

|

10mm

|

10mm

|

|

|

The front and lower knife shaft diameter

|

∅40mm

|

∅40mm

|

∅50mm

|

|

|

The left and right knife shaft move up and down

|

30mm

|

30mm

|

20mm

|

|

|

The left and right shaft shaft diameter

|

∅40mm

|

∅40mm

|

∅40mm

|

|

|

The front and rear movement amount of the upper blade shaft

|

20mm

|

20mm

|

10mm

|

|

|

The upper knife shaft

|

∅40mm

|

∅40mm

|

∅50mm

|

|

|

Tool maximum rotation diameter

|

|

|

|

|

|

Upper the knife shaft

|

∅115mm

|

∅145mm

|

∅145mm

|

|

|

Front and lower knife shaft

|

∅100mm

|

∅120mm

|

∅125mm

|

|

|

Left, right stand knife shaft

|

∅115mm

|

∅145mm

|

∅145mm

|

|

|

Power of motor

|

|

|

|

|

|

Upper knife shaft

|

4.0kw

|

7.5kw

|

11.0kw

|

|

|

Lower knife shaft

|

3kw

|

4kw

|

5.5kw

|

|

|

Left standing knife shaft

|

3kw

|

5.5kw

|

7.5kw

|

|

|

Right vertical knife shaft

|

33kw

|

5.5kw

|

5.5kw

|

|

|

Feed delivery motor

|

2.2kw

|

3.0kw

|

3.0kw

|

|

|

Lift motor

|

0.37kw

|

0.75kw

|

0.75kw

|

|

|

Total machine tool power

|

15.57kw

|

26.25kw

|

33.25kw

|

|

|

Air source pressure

|

0.25-0.3MPa

|

0.25-0.3MPa

|

0.25-0.3MPa

|

|

|

Compressed air is required for

|

0.1m³/min

|

0.1m³/min

|

0.1m³/min

|

|

|

Machine tool size

(length x width x height) |

2400*1300*1500mm

|

3300*1600*1500mm

|

3500*2000*1650mm

|

|

|

Machine tool weight

|

1400kg.

|

2800kg.

|

3500kg.

|

|

Qingdao Zhongding Machinery Co., Ltd is a leading company of specializing in manufacturing and exporting woodworking machine for more than 20 years. We perform a variety of services to not only supply our clients with top quality woodworking machinery but also adequate maintenance, spare parts and technical advice.

Our products mainly include Precise Panel Saw, Edge Banding Machine, Multiple Drilling Machine, Press Machine etc., which have been exported to lots of countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, and Australia.

We have established complete sales system.Our company has got ISO9001 international system certificate and CE security certificate.

Our products mainly include Precise Panel Saw, Edge Banding Machine, Multiple Drilling Machine, Press Machine etc., which have been exported to lots of countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, and Australia.

We have established complete sales system.Our company has got ISO9001 international system certificate and CE security certificate.

Hot Searches