- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

250 mm

-

Dimension:

-

3500*1580*2400

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ZFY

-

Year:

-

2023

-

Weight (KG):

-

6400

-

Motor Power (kw):

-

11 kw

-

Control Axis::

-

6+1 axis

-

CNC Control System::

-

DELEM

-

Electrical Components::

-

Schneider

-

Servo motor/ Servo drive::

-

ESTUN

-

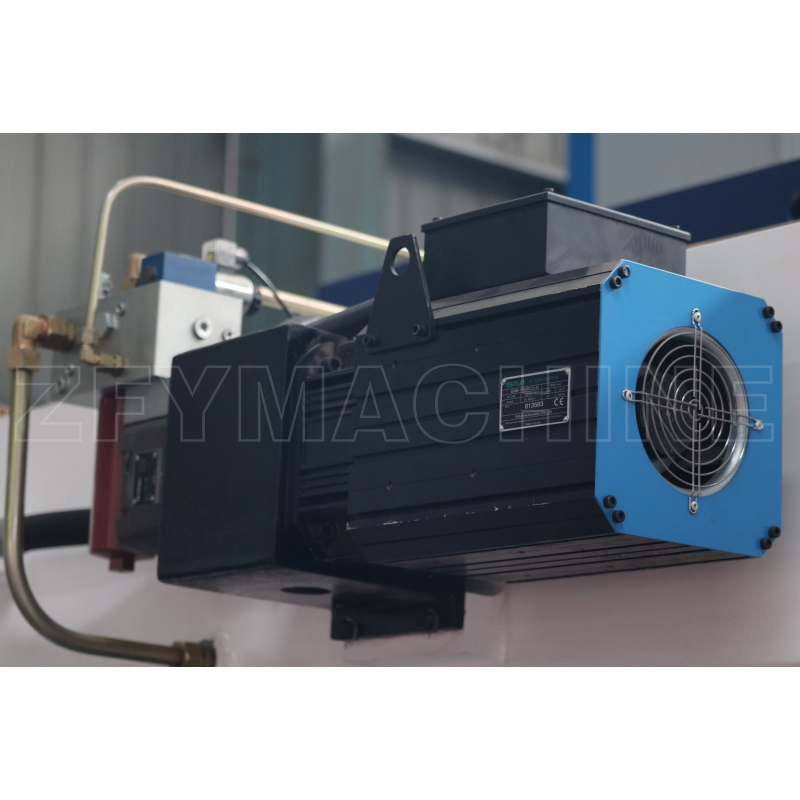

Main Motor::

-

Siemens

-

Linear guide and ball screw::

-

HIWIN

-

Hydraulic system::

-

Rextroth

-

Grating ruler::

-

FAGOR

-

Safety::

-

Laser protection

-

Punch and die::

-

Custom-made

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

250 mm

-

Dimension:

-

3500*1580*2400

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ZFY

-

Year:

-

2023

-

Weight (KG):

-

6400

-

Motor Power (kw):

-

11 kw

-

Control Axis::

-

6+1 axis

-

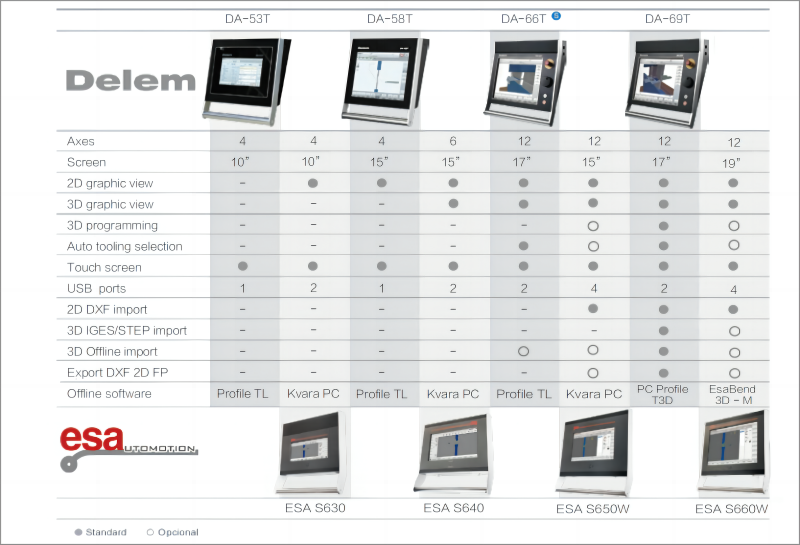

CNC Control System::

-

DELEM

-

Electrical Components::

-

Schneider

-

Servo motor/ Servo drive::

-

ESTUN

-

Main Motor::

-

Siemens

-

Linear guide and ball screw::

-

HIWIN

-

Hydraulic system::

-

Rextroth

-

Grating ruler::

-

FAGOR

-

Safety::

-

Laser protection

-

Punch and die::

-

Custom-made

Product Description

ZFY Genius Series CNC Press Brakes

A territory with a consolidated technological background and the inventiveness of the ZFY family are the ingredients of the birth of ZFY Brand, One of the company to apply hybrid & electric servo bending technology to the bending of sheet metal, thus gaining a substantial technological edge over the competition.

It is a lean and dynamic company that builds customised automated cutting, welding and bending systems and has a widespread sales network around the world.

Details Images

CNC CONTROL SYSTEM

We have become a partnership with the industry's top brands, DELEM,ESA,CYBELEC

CNC BACK GAUGE

ZFY press brake are provided are equipped with BGA Series CNC backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

BGA-2

2 axes Y1-Y2-X-R

BGA-4

4 axes Y1-Y2-X-R-Z1-Z2

BGA-6

6 axes Y1-Y2-X1-X2-R1-R2-Z1-Z2

CNC CROWNING SYSTEM

This ZFY CNC Crowning system enables the user to offset deformations of the beam while bending. thus, the angle is kept constant along the entire plate length.

HYDRAULIC SYSTEM

This is the ZFY standard hydraulic system, composed of Siemens main motor, SUNNY oil pump, and Rexroth valve group, achieving stable and efficient running of the press brake.

SERVO HYDRAULIC SYSTEM

The main motor can be upgraded to an ESTUN servo motor for more energy-efficient and low-noise operation.

SERVO PRO HYDRAULIC SYSTEM

The ZFY PRO series hydraulic system can be upgraded to a dual servo fully electric machine. By using SYNCHO technology, two axes are controlled during the bending process, enabling independent compensation for the Y1 and Y2 axes.

OPTIONAL LASER PROTECTION DEVICE

The front laser protection can avoid the danger in the bending process and protect the operation safety to the greatest extent.

QUICK CLAMPING

When there are frequent tooling changes,punches or dies can be changed over in a short time by using the quick clamps. The time saved will be more how many times it will be necessary to change the tools.

OPTIONAL WILA CLAMPING

The WILA’s state-of-the-art clamp systems offer optional for the ultimate efficiently changing tools with Smart Tool Locator® (STL)* have made the changeover process easier and safer. and Premium is available as an option.

PRESS BRAKE TOOLINGS

We help customers design toolings with maximum efficiency based on their product needs, support customized service, and bring to customers to creating value.

Products List

|

Model

|

Bending length

|

Normal force

|

Dimension

|

Weight

|

|

|

mm

|

kn

|

mm

|

kgs

|

|

ZPB-8032

|

3200

|

800

|

3500*1550*2100

|

6050

|

|

ZPB-11032

|

3200

|

1100

|

3500*1580*2400

|

6600

|

|

ZPB-13032

|

3200

|

1300

|

3500*1600*2460

|

7120

|

|

ZPB-17540

|

4000

|

1750

|

4300*1680*2550

|

11000

|

|

ZPB-22040

|

4000

|

2200

|

4300*1700*2600

|

13000

|

|

ZPB-50060

|

6000

|

5000

|

6500*2810*4500

|

30500

|

Remark:

The data only represents the models in the above product list for reference only. For more information, please contact us now.

Why Choose Us

ZFY Machine Manufactory (Anhui) Co.,Ltd---

www.zfymachine.com

As a leading manufacturer in the sheet metal working machinery & Automatic

PRESS BRAKES / LASER CUTTING MACHINES / SHEARING MACHINE / V-GROOVING MACHINE / ROLLING MACHINE / IRONWORKS / PUNCHING MACHINES.

· Found in 2005

· 109 Employee

· Sold 80+ Countries

· 500+ sets Produced Yearly

· 1V1 After sale team

· 8 Years Warranty

· Free Spare Parts Replace

· Oversea Engineers Training & Installation

Our Manufacturing Ablity

Certifications

What People Say

FAQ

Q:

How about our after-sales service?

A:

ZFY exclusive overseas engineers on-site service.

24-hour telephone line and video conference are available for any questions.

We have an experienced team of service technicians for work-hard solutions.

Q:

Can you supply the relevant documentation?

A:

Of course, we can provide most documentation including Certificates of Analysis /Conformance; Product quality certificates; BL; CO, and other export documents where required.

Q:

What is the average lead time?

A:

We have a lot of standard machine tools in stock in order for faster delivery, and they can be shipped within 3 days once confirmed the order. For mass production, the lead time is 15-25 days. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases, we will try to accommodate your needs. In most cases, we are able to do so.

Q:

What kinds of payment methods do you accept?

A:

We can trade through Alibaba.

You can also make the payment to our bank account by TT, LC at sight, and LC after sight. Such as 30% deposit in advance, 70% balance against the copy of B/L but open to negotiation.

Q:

What is the product warranty?

A:

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction.

Q:

Do you guarantee safe and secure delivery of products?

A:

Yes, we always use high-quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature-sensitive items. Specialist packaging and non-standard packing requirements are provided by us for free.

Q:

How about the shipping fees?

A:

The shipping cost depends on the way you choose to get the goods. Express is normally the quickest but also the most expensive way. Sea freight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of the amount, weight, and way. Please contact us for further information.

Hot Searches