- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

2 KW

-

Dimension(L*W*H):

-

360x300x380mm

-

Warranty:

-

one year

-

After-sales Service Provided:

-

No overseas service provided

-

target:

-

customized

-

Specimen chamber:

-

Fused glass tube

-

Size:

-

customized

-

Delivery:

-

timely

-

Weight:

-

60KG

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kejia

-

Model Number:

-

Compact magnetron plasma sputtering coater

-

Voltage:

-

220V

-

Power:

-

2 KW

-

Dimension(L*W*H):

-

360x300x380mm

-

Warranty:

-

one year

-

After-sales Service Provided:

-

No overseas service provided

-

target:

-

customized

-

Specimen chamber:

-

Fused glass tube

-

Size:

-

customized

-

Delivery:

-

timely

-

Weight:

-

60KG

-

Certification:

-

CE

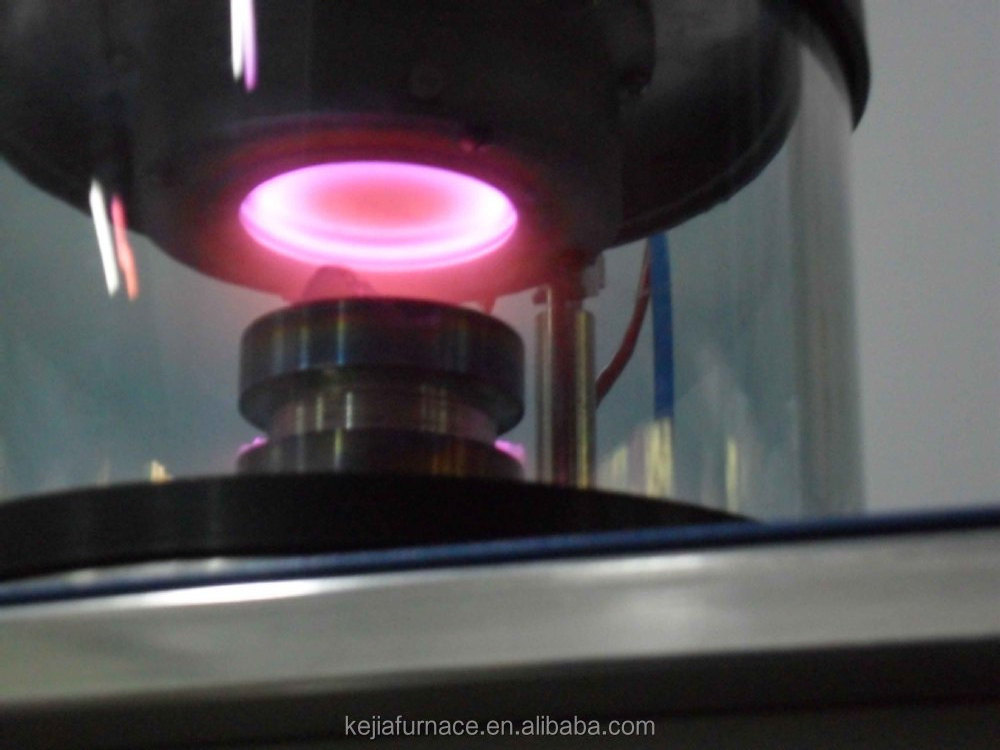

Compact Magnetron Plasma Sputtering Coater with Vacuum Pump & Water Chiller

KJ -1100X-SPC-16M is a single target Compact Magnetron Plasma Sputtering Coater with Double Step Rotary Vane

Vacuum Pump . One magnetron with Peltier cooling device is installed on top of machine. One Gold target and

vacuum pump are included for immediate use.

Technical parameter of compact Magnetron Plasma Sputtering Coater

|

Input Voltage |

220V (110V is available with a transformer at extra cost), 50/60 Hz |

|

Input Power |

< 2000W (including pump) |

|

Output Power |

1600VDC 50mA max. |

|

Specimen chamber |

Fused glass tube, 160 mm Dia. x 120mm Height |

|

Specimen stage |

One 50 mm Dia.sample stage Max. coating area: 45 mmilable

|

|

Accessories included |

Double Step Rotary Vane Vacuum Pump (external) with Pirani gauge and Vapor trap eliminates the oil mist Stainless steel bellows with KFD-25 adapter and clamps 16L/min recirculating water chiller is included to cool magnetron head.

|

|

Gas Atmosphere |

One needle valve installed to allow Ar gas inlet to achieve better plasma coating |

|

Target |

One Au target: 50 mm dia. x 0.12 mm, 1pcs is included |

|

Overall Dimensions |

L360mm x W300mm x H380mm |

|

Warranty & Certificate |

One year limited with lifetime support CE certified |

|

Knowledge of Sputter Coating |

For the best film strength, please use plasma cleaner to clean the sample surface before coating For coating light weight metallic materials such as Al. Zinc and graphite, the sputtering coating is not efficient due to low energy, please consider using a thermal evaporating coater

|