- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

100 KG

-

Power (kW):

-

220

-

type:

-

wood drying equipment

-

heating ways:

-

wood heating ,gas heating ,electricty heating

-

power:

-

10kw-57kw

-

shape:

-

container style

-

colour:

-

green ,blue silver

-

Capacity:

-

20-200cubic meter

-

heating wood thickness:

-

5cm-10cm

-

Certification:

-

CE/ISO

-

Weight:

-

1000kg

-

power supply:

-

380V/415V/220V 3 PHASE 50HZ

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

luy

-

Machine Type:

-

other

-

Weight (KG):

-

100 KG

-

Power (kW):

-

220

-

type:

-

wood drying equipment

-

heating ways:

-

wood heating ,gas heating ,electricty heating

-

power:

-

10kw-57kw

-

shape:

-

container style

-

colour:

-

green ,blue silver

-

Capacity:

-

20-200cubic meter

-

heating wood thickness:

-

5cm-10cm

-

Certification:

-

CE/ISO

-

Weight:

-

1000kg

-

power supply:

-

380V/415V/220V 3 PHASE 50HZ

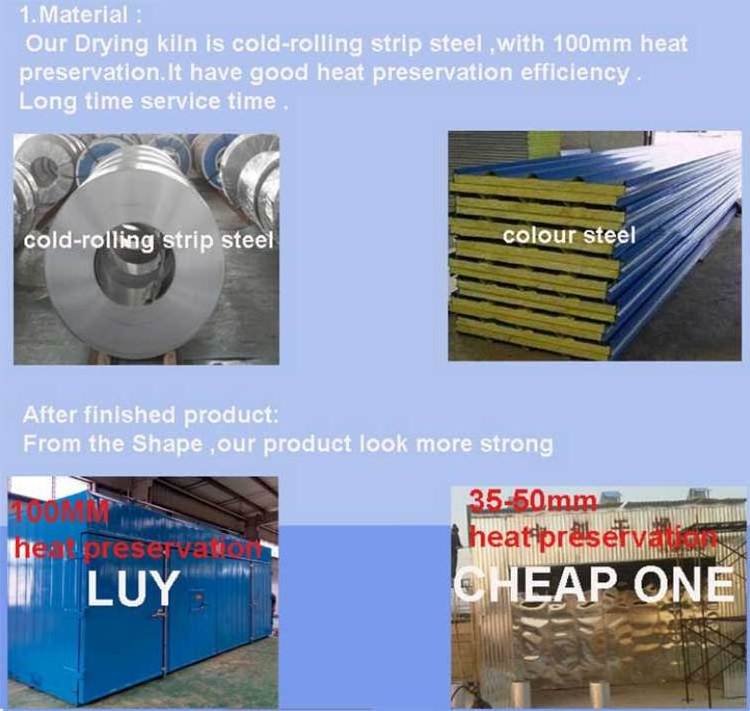

Hot sale factory direct price timber drying chamber wood vacuum dryer high quality machine

Related parameters :

| Type | wood drying equipment |

| Heating ways | wood heating ,gas heating ,electricty heating |

| Power | 10kw-57kw |

| Shape | container style |

| Colour | green ,blue silver |

| Capacity | 20-200cubic meter |

| Heating wood thickness | 5cm-10cm |

| Certification | CE/ISO |

| Weight | 1000kg |

| Power supply | 380V/415V/220V 3 PHASE 50HZ |

This equipment is made up from burning equipment and wood drying kiln ,The hot air drying kin working principle is after burning prdouce heat energy to heat inside kiln air. From the bottom of fan of hot air stove via pipe enter into furnace , to heating air.The inside circulation fan transfer hot air to heat wood .During drying ,if they need steam ,the steam supply by steam generator .If there is one furnace with two room and more rooms ,there is insert valve to control temperature .There is also discharge moisure.

Buying Guides:

| defect name | reason | solve method |

| buckling deformation | 1.big distance of division bar.Its thickness is inconsistent |

Wood crib accumulation is reasonable

The thickness of division is uniform |

| 2.the division bar from up to down is not on vertical line | Every article must be up and down on the a vertical line | |

| 3.the temperaure is over high ,the moisture is too low ,dry nonuniform | strickly operation ,make balance treatment | |

| moisture is not uniformity |

1.Low air velocity

2.Improper Storage 3.heating pipe is uniform |

1.inspect fan ,improve ventilation

2.according to requesment to make storange 3.adjustment heating system |

| surface crack | 1.drying temperature is high ,moisture is low | 1.choose softer drying schedule |

| 2.Wood failure to eliminate internal stress | 2.To make treatement during initial stage ,middle stage | |

| 3.air flow is uniform to make furnance temperatute uniform | 3.check wind flow and timber crib to make sure uniform ventilation | |

| 4.after drying ,the stress is not solve | 4.do after treatment | |

| 5.preparation drying wood has crack,without treatment | 5.do initial and middle treatment | |

| inside crack | 1.initial stress is too big ,to form into surface harness ,and without deal with in time | 1.to make infision ,middle treatment |

| 2.misoperation ,rapid adjustment temperature | 2.adopt soft standard,strickly control temperature wetness degree | |

| 3.Tree structure relaxation,drying is not reasonable | 3.adopt soft standard,strickly control temperature wetness degree | |

| end crack | 1.wood crip storange is not good ,both ends is out of parting stop | 1.to make right wood crip storange,according to regulation to layout |

| 2.the wind flow of beginning of wood is big | 2.The beginning of wood to paint asphalt ,and wax | |

| 3.drying basic standard I hard | 3.adopt soft standard,strickly control temperature wetness degree | |

| wood mouldy | 1.low temperatute ,wetness is big | 1.to make wood crip reasonably,improve temperature ,and reduce moiture |

| 2.wood crip is slow flowing | 2.increase wind flow | |

| moisture content gradient is big | 1.hardness standard ,drying surface quickly | 1.increase wind speed |

| 2.misoperation ,rapid adjustment temperature | 2.according to reasonal standard | |

| 3.treatment time is not enough | 3.to make middle ,after treatment |