- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ACE

-

Voltage:

-

110V-440V

-

Power:

-

0.75KW-115KW

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1300

-

Material:

-

stainless steel 304 316L

-

Agitator type:

-

paddle/propeller/anchor agitator

-

Heating ways:

-

Electric / Steam / outer circulated heating

-

Speed:

-

0-3000r/min

-

Structure:

-

single layer , double jacket , insulation layer

-

Function:

-

Heating , cooling , mixing , insulation

-

Usage:

-

Food ,chemical , beverage , dairy ,ects

-

surface treatment:

-

Electrical polish,Mirror polish,Sand polish ,Aicd washing,2B

-

Tags:

-

high pressure/electric heating/stainless steel

-

Product name:

-

reactor

Quick Details

-

Capacity:

-

100~30,000l

-

Marketing Type:

-

New Products 2024

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

110V-440V

-

Power:

-

0.75KW-115KW

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1300

-

Material:

-

stainless steel 304 316L

-

Agitator type:

-

paddle/propeller/anchor agitator

-

Heating ways:

-

Electric / Steam / outer circulated heating

-

Speed:

-

0-3000r/min

-

Structure:

-

single layer , double jacket , insulation layer

-

Function:

-

Heating , cooling , mixing , insulation

-

Usage:

-

Food ,chemical , beverage , dairy ,ects

-

surface treatment:

-

Electrical polish,Mirror polish,Sand polish ,Aicd washing,2B

-

Tags:

-

high pressure/electric heating/stainless steel

-

Product name:

-

reactor

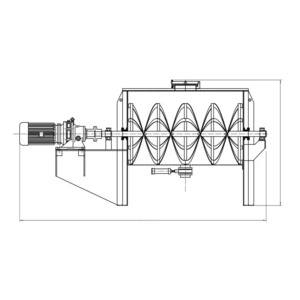

Type Blade With Mixer Reactor Vessel Spices Mixing Ribbon Blender

Custom Made 50L- 30,000L, 22 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please contact us for the offer.

Video

Products Description

Whether it is processing one ingredient or multiple ingredients into the final product, your chemical reactions depend heavily on the right heat transfer and agitation. You don't want to compromise your quality on even one batch. With more than 21 years of pressure vessel experience under our belts, we can help you design and manufacture your reactor to make sure your process is at its highest level of performance.

Reference technical parameters

1. Tank body: stainless steel (SUS304, SUS316L) material, the inner surface of the mirror polishing,

2. Can be online CIP cleaning, SIP sterilization, in line with health norms

3. Mixing device: optional box-type, anchor type, such as pulp

4. Heating and cooling: steam heating or electric heating can be used

5. Stirring shaft seal with pressure hygiene mechanical seal device to maintain the working pressure inside the tank and to prevent leakage of materials within the tank.

6. Support type According to the operational requirements of the use of hanging ear-type or floor leg type.

Agitation for Efficiency

Agitation can make the difference between a reaction working or not working. It also affects high and low yields by making sure the temperatures are spread evenly and your ingredients mixed thoroughly as your product is processing. We work with you and your specific process to help eliminate the hot and cold spots and reach the appropriate mixing levels required for an efficient reaction.

This reactor is used for hydrolysis, neutralization, crystallization, distillation and evaporation in the fields of chemicals, food, light industry etc. The reactor body is made of sus304, sus316l stainless steel. Several mixing type is available

Structure

1. The equipment is mainly composed of three parts: a cylinder, an integral jacket and an outer covering. The outer covering and the jacket are filled with insulation medium, and the tank top is equipped with a stirrer.

2. The pressure inside the jacket is determined according to customer requirements.

3. The materials are all high-quality stainless steel.

|

Reactor Tank (Accept customized)

|

|

|

|

|||

|

Profile/type

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

|||

|

Material

|

SS304 or SS316L

|

|

|

|||

|

Volume

|

50L-30T (Customized)

|

|

|

|||

|

Pressure

|

Vacuum-1Mpa

|

|

|

|||

|

Tank Type

|

Vertical type/Horizontal type/Mobile type

|

|

|

|||

|

Structure

|

one layer

|

Inner layer+jacket

|

inner layer+jacket+insulation

|

|||

|

heating way

|

Electric/Steam Heating

|

|

|

|||

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

|

|||

|

Outside Finish

|

2B or Satin Finish

|

|

|

|||

|

Stirrer type

|

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

|

|||

|

|

|

|

|

|||

|

Power

|

0.55~55KW

|

|

|

|||

|

Voltage

|

110V~480V

|

|

|

|||

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

|||

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

|||

|

PARTS DETAILS

|

1.Quick open manhole / Pressure manhole

|

|

|

|||

|

|

2.Various types of CIP cleaners

|

|

|

|||

|

|

3.Sterile respirator

|

|

|

|||

|

|

4.Adjustable Legs

|

|

|

|||

|

|

5.Inlet and Outlet sanitary valve

|

|

|

|||

|

|

6.Thermometer (According to customer requirements )

|

|

|

|||

|

|

7.Paddle blender .(According to customer requirements)

|

|

|

|||

|

|

8.Liquid level meter and lever controller (According to customer requirements)

|

|

|

|||

|

|

9.Ladder

|

|

|

|||

|

Application

|

Food, Beverage, biological, honey, chocolate, alcohol, chemical industry etc

|

|

|

|||

|

We can customize the equipment according to customer requirements.

|

|

|

|

|||

Have different kinds of agitators:

1, Bottom magnetic agitator with propeller impeller, speed from 50-400rpm or 50-800rpm. This kind of agitator is mixing thin viscosity, such as eye drop, injection, CIP liquid, water, etc.

2, Top mechanical agitator with propeller impeller, speed at fix 71rpm or adjustable 20-200rpm or special requirement. This kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.

3, Top mechanical agitator with anchor or frame impeller, speed is from 10-70rpm. It is mixing higher viscosity, such as sediment or viscosity oral liquid, etc.

4, Top emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.

5, Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.

Details Images

Certifications

FAQ

|

Q

|

Are you trade or manufacturer?

|

|

|

|

|||

|

A

|

We are a factory with an international sales company specialized in support for global distributors.

|

|

|

|

|||

|

Q

|

Can you provide instant technical consulting services?

|

|

|

|

|||

|

A

|

We are able to discuss technical details and offer suggestions over the phone in English.

You can get the answers in minutes, instead of days. |

|

|

|

|||

|

Q

|

What's the difference between Ready-To-Ship and Customized products?

|

|

|

|

|||

|

A

|

Some of RTS standard products are in stock and ready to ship in 2-3 days.

We can also quick design and make the drawings for customer requirements, then begin the production. |

|

|

|

|||

|

Q

|

What is the payment terms?

|

|

|

|

|||

|

A

|

We accept Alibaba Trade Assurance Order, also can T/T and L/C.

|

|

|

|

|||

|

Q

|

How to choose the shipment way?

|

|

|

|

|||

|

A

|

It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers)

|

|

|

|

|||

|

Q

|

How about the after-sales service?

|

|

|

|

|||

|

A

|

Fast after-sales support. Our products have a one-year warranty and free permanent consulting services.

|

|

|

|

|||

Contact Us

Hot Searches