1.Low Machinery Investment:

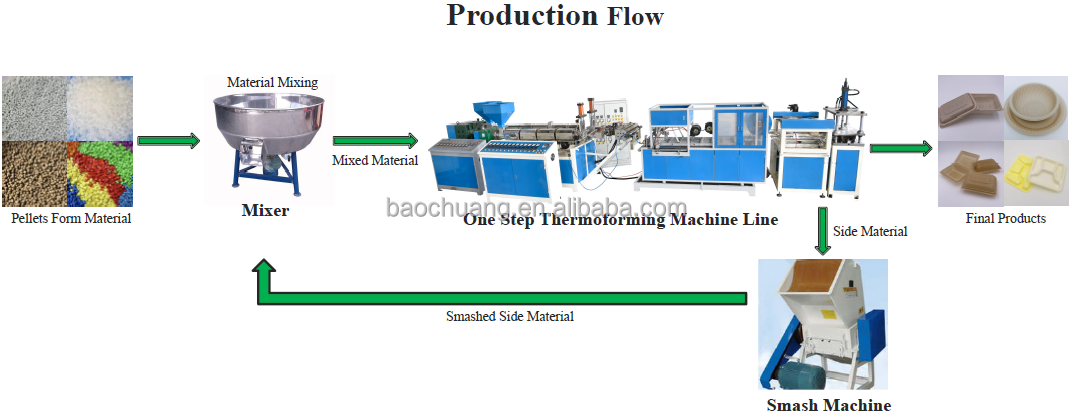

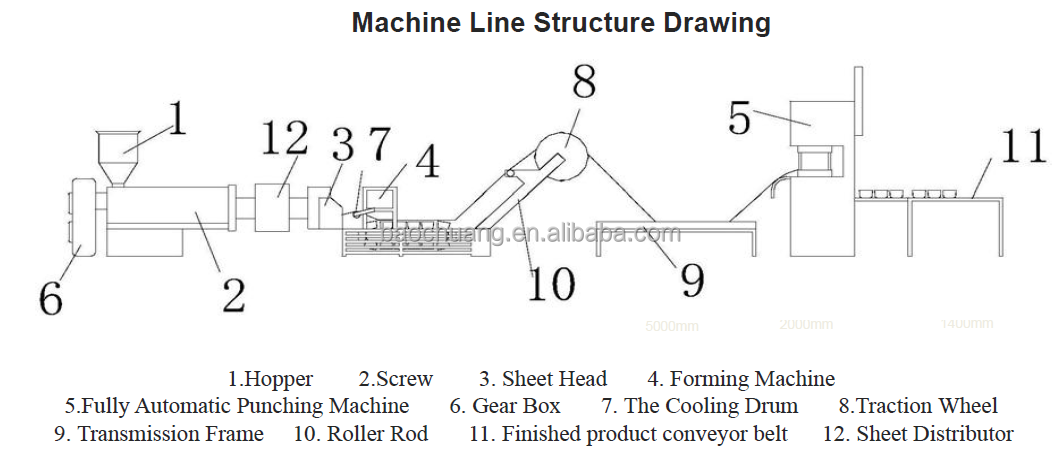

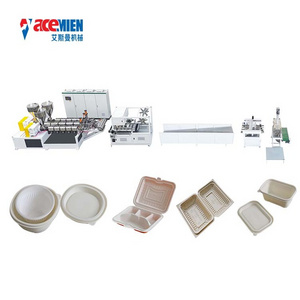

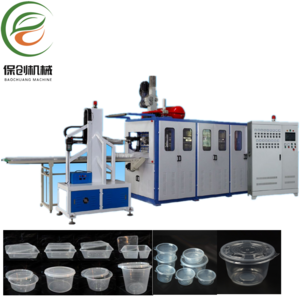

Each line comes with all associate equipment that clients need to produce products: sheet extruding machine, forming machine, fully automatic hydraulic punching machine, mixer, smash machine, one set of customized mold and punching knife.

2.Low Energy Consumption:

The sheet extruding machine produces sheet directly to product forming and punching.No secondary heating requires.

3.Adapt Multi Material:

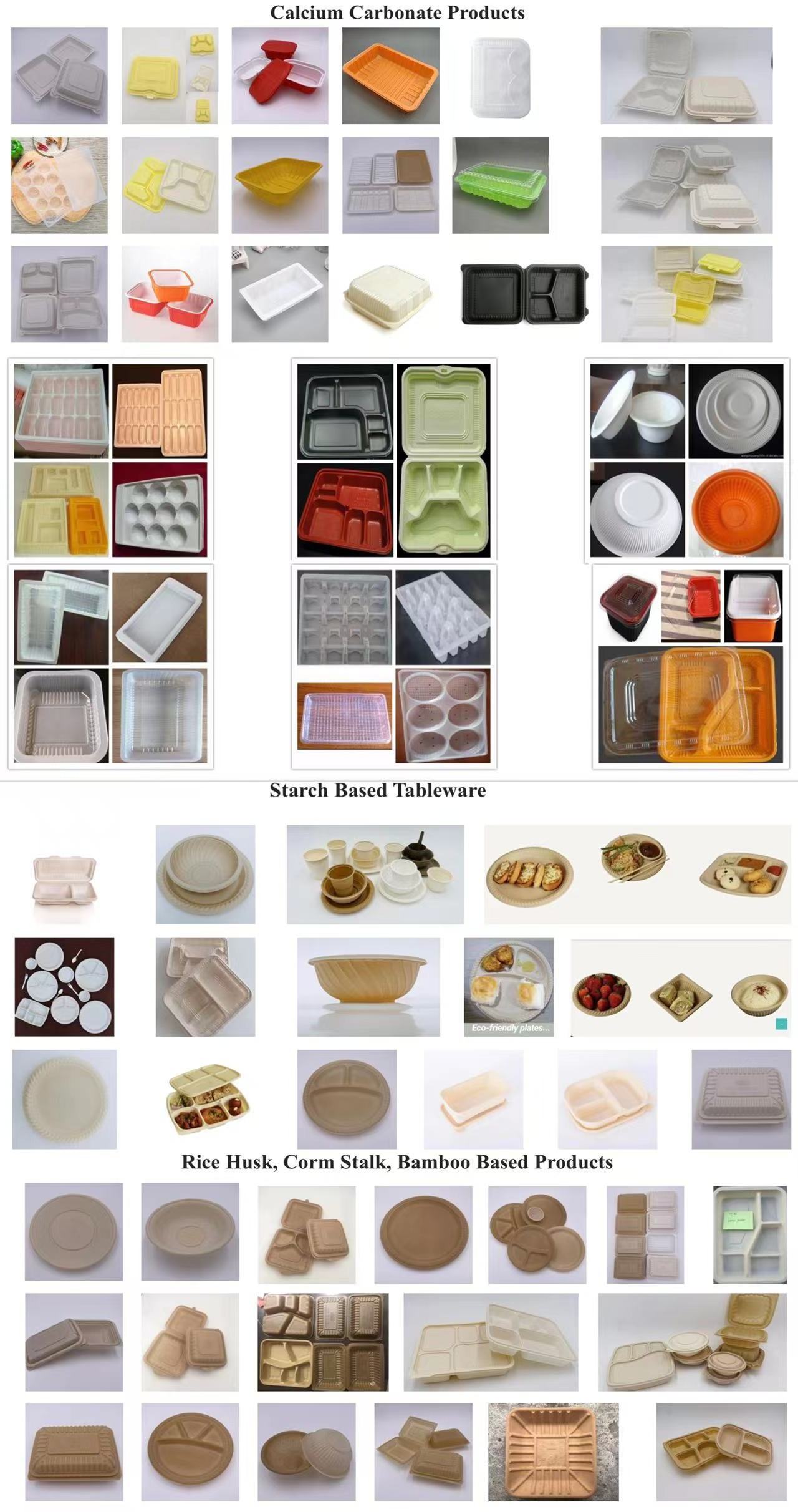

ps, pp with calcium, rice husk, bamboo, talcium, starch, straw, bamboo and other plant fiber.

4.Adapt Plastic Free Material:

PLA, PBAT etc

5.Multi Application:

By changing mold, the machine line is able to produce lunch box, food container, clamshell box, market tray, food tray, bowl, plate etc. All mold can be customized according to clients needs.

6.High Automation and Easy Operation:

Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage.

7.No material wastage:

Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution and no water pollution during production process.

8.Durable and Reliable:

The machine line is able to be running 24/7 without problem. Only Require basic maintenance.