- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

000000

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Si Hai

-

Model Number:

-

SH-922

-

Type:

-

silicone adhesive

-

Appearance:

-

colorless or light yellow semi transparent liquid

-

Diluting agent:

-

methylbenzene /toluene

-

Viscosity:

-

no less than 20000cs

-

Solid content:

-

60±2

-

Density:

-

0.98-1.02

-

Application:

-

refractory mica tape

-

free samples:

-

500g

Quick Details

-

CAS No.:

-

63148-62-9/9016-00-6/9006-65-9

-

Other Names:

-

polyorganosiloxane

-

MF:

-

000000

-

EINECS No.:

-

000000

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Si Hai

-

Model Number:

-

SH-922

-

Type:

-

silicone adhesive

-

Appearance:

-

colorless or light yellow semi transparent liquid

-

Diluting agent:

-

methylbenzene /toluene

-

Viscosity:

-

no less than 20000cs

-

Solid content:

-

60±2

-

Density:

-

0.98-1.02

-

Application:

-

refractory mica tape

-

free samples:

-

500g

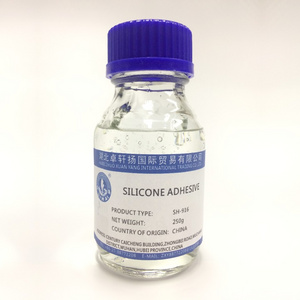

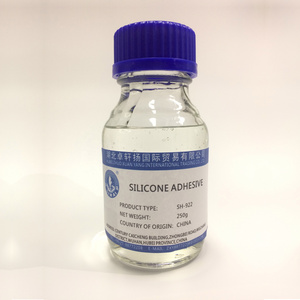

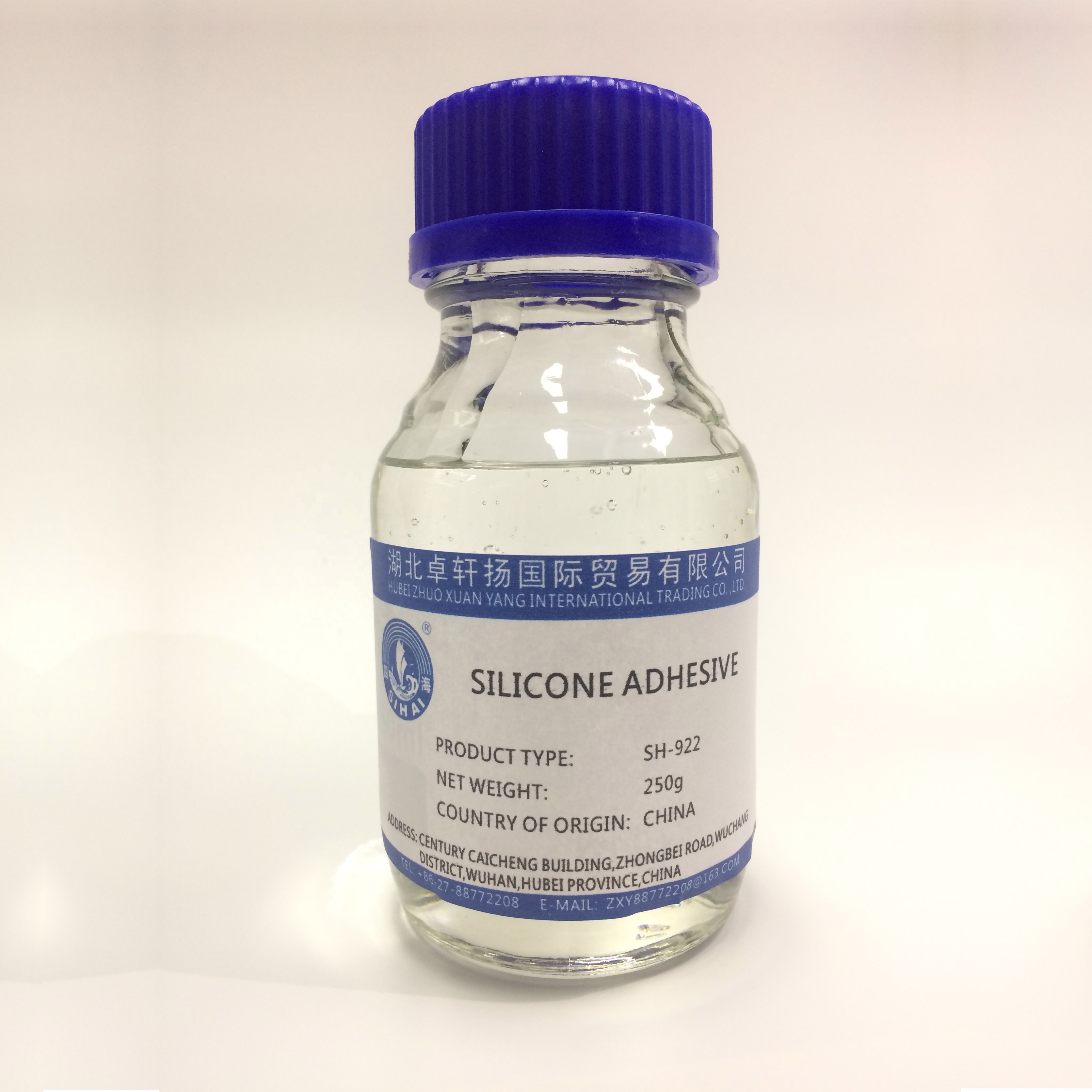

silicone removable adhesive High temperature resistant SH-922 for mica adhesive and mica tape

This product is a dispersible liquid of the polydimethylsiloxane and resin among the methylbenzene, which is highly viscous and has good adhesion. It is a kind of goods with low smoke, non- toxic, good stability, high temperature resistant and no carbon deposition. It also has the characteristics of excellent weather resistance, moisture resistance and electrical insulation.

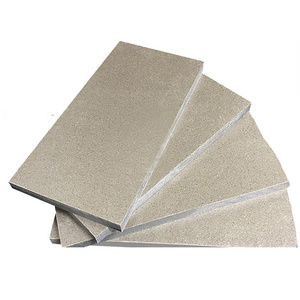

Design application

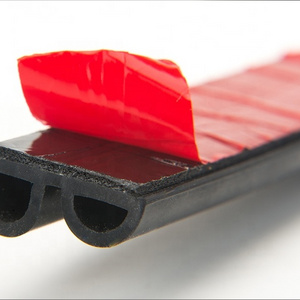

- It is used for the production of refractory mica tape and high temperature pressure sensitive adhesive tape.

- It is used for shading and sheet metal tape.

- It is used alone as a variety of adhesive, fixed or supported adhesives.

Basic technical data

| Appearance | colorless or light yellow semi transparent liquid, no mechanical impurities |

| Diluting agent | methylbenzene /toluene |

| Viscosity (25℃mm2.S-1) | no less than 20000cs |

| Solid content (150℃,2h,%) | 60±2 |

| Density (25℃) | 0.98-1.02 |

| Free Samples | 500g |

Instructions for usage

- It is a fast dry adhesive, with short curing time and strong stickiness. After curing, mica belt is dry and soft, will not be adhesive.

- The SH922A binder can be directly coated on the base material with traditional tape coating equipment. You can further dilute the adhesive with compatible solvent such as methylbenzene, dimetheylbenzene. The advisable working liquid concentration is 15~20%. When using the solvents, please ensure that it is good ventilated and comply with safety precautions and regulations of solvent suppliers.

- The peroxide class can be used as curing agent, such as BPO or DPP, and BPO is recommended. The advisable dosage is 1.0-3.0% of the 100% adhesive. The curing agent can be used to accelerate the curing speed or allow the curing at low temperature, and it can also improve the cohesion strength of the adhesive and improve the adhesion property of the adhesive.

- When using BPO, it should be dissolved in toluene, going to be 10% solution, which can achieve the best mixing with the adhesive. The mixed peroxide dispersible liquid should be used up within 1-2 days. That is because peroxide will lose its activity quickly in the solvent. The sufficient dispersion of adhesive and peroxide in the mixing process is the necessary condition to ensure the consistency of the finished product.

- Surface curing cycle: 60 ~ 90 ℃ * 1 min Eliminate the solvent to ensure that there is no solvent in the glue when it enters the solidification zone; 140 ~ 170 ℃ * 2 min, through the thermal curing to further improve the adhesive force, cohesive strength and initial adhesion.

- If the equipment and substrate allow higher curing temperature, the curing time can be shortened. Compared to low temperature curing, the high curing temperature can increase the cohesive strength of the adhesive in a shorter time.