- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RICHI

-

Voltage:

-

380V/415V/440V

-

Dimension(L*W*H):

-

2200*1500*2050MM

-

Motor Power (Kw):

-

22-280Kw

-

Power (kW):

-

37Kw

-

Weight (KG):

-

2500 KG

-

Marketing Type:

-

CE Certified Machines

-

Name:

-

Agro Waste Wood Pellet Machine

-

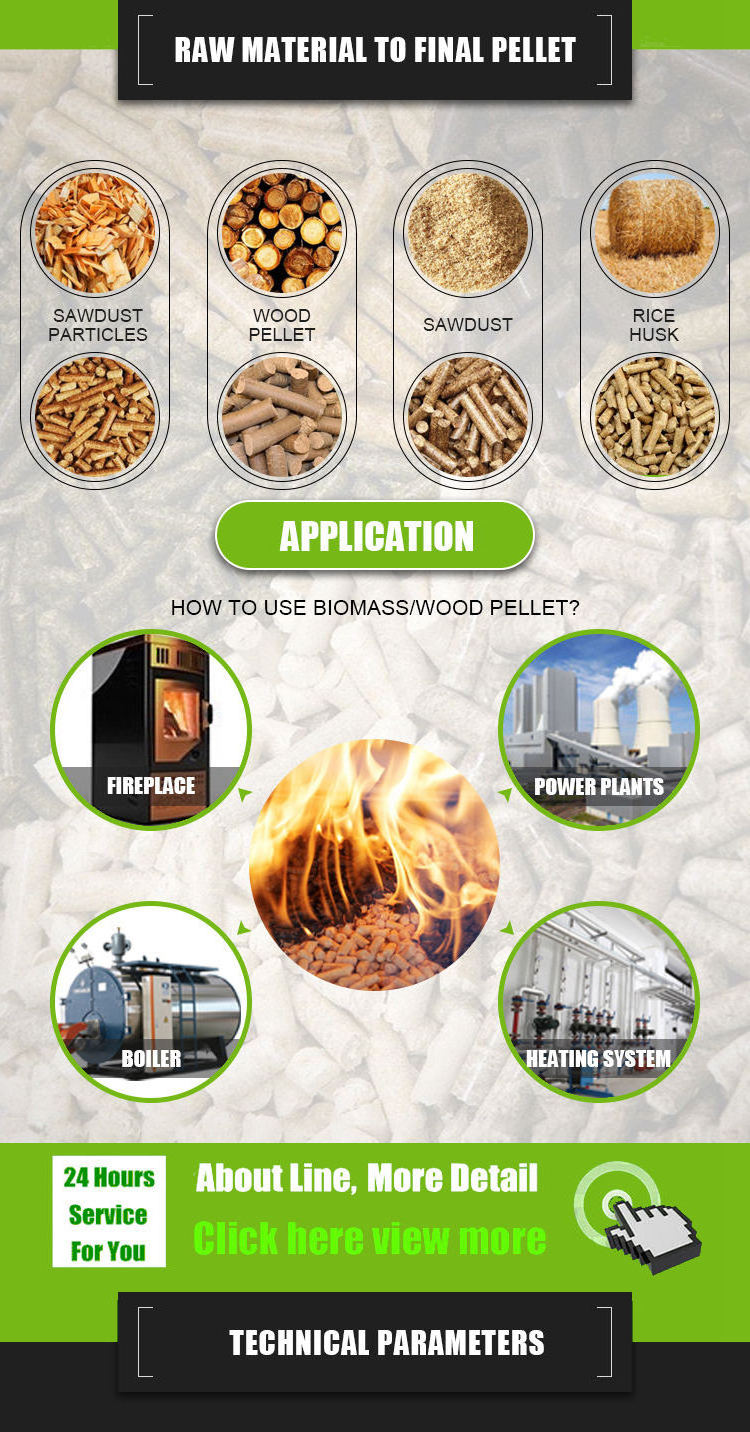

Application:

-

Make Biomass Pellets

-

Capacity:

-

0.3-0.4TPH for single wood pellet machine to product wood pellet

-

Type:

-

Ring Die Wood Pellet Mill

-

Keywords:

-

Wood Pellet Machine

-

Motor:

-

Siemens Motor

-

Color:

-

Green White

-

Advantage:

-

Long Life Usgae

-

Pellet size:

-

2-12mm

-

Material:

-

42CrMo for Core Part Ring Die

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

300 - 2000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RICHI

-

Voltage:

-

380V/415V/440V

-

Dimension(L*W*H):

-

2200*1500*2050MM

-

Motor Power (Kw):

-

22-280Kw

-

Power (kW):

-

37Kw

-

Weight (KG):

-

2500 KG

-

Marketing Type:

-

CE Certified Machines

-

Name:

-

Agro Waste Wood Pellet Machine

-

Application:

-

Make Biomass Pellets

-

Capacity:

-

0.3-0.4TPH for single wood pellet machine to product wood pellet

-

Type:

-

Ring Die Wood Pellet Mill

-

Keywords:

-

Wood Pellet Machine

-

Motor:

-

Siemens Motor

-

Color:

-

Green White

-

Advantage:

-

Long Life Usgae

-

Pellet size:

-

2-12mm

-

Material:

-

42CrMo for Core Part Ring Die

| MZLH Series Ring Die Pellet Machine - Agro Waste Alfafa Bentonite Cat Litter Bio Fuel Coconut Shell Cotton Hull Pellet Machine |

| Model | Constituent part |

Power (KW) |

Pellet Size (mm) |

Capacity (Wood Sawdust, Biomass,Paper) |

Capacity (Grass or Straw) |

Capacity (Organic Fertilizer) |

Weight (KG) |

Dimension (CM) |

| MZLH-320 | Anti-Caking Feeder | 1.5KW | 2-12mm | 0.3-0.4T/H | 0.6-0.8T/H | 1-2T/H | 2500KG | 220*90*130 |

| Force Feeder | 0.55KW | |||||||

| Pellet Machine | 37KW | |||||||

| MZLH-350 | Anti-Caking Feeder | 1.5KW | 2-12mm | 0.5-0.8T/H | 0.8-1T/H | 3-4T/H | 3500KG | 250*110*160 |

| Force Feeder | 0.55KW | |||||||

| Pellet Machine | 55KW | |||||||

| MZLH-420 | Anti-Caking Feeder | 1.5KW | 2-12mm | 1-1.5T/H | 1.5-2T/H | 5-6T/H | 4000KG | 280*115*173 |

| Force Feeder | 0.55KW | |||||||

| Pellet Machine | 110KW | |||||||

| MZLH-520 | Anti-Caking Feeder | 2.2KW | 2-12mm | 1.5-2.5T/H | 3-4T/H | 7-8T/H | 4500KG | 300*126*186 |

| Force Feeder | 0.75KW | |||||||

| Pellet Machine | 160KW | |||||||

| The Futuer of Wood Pellet Machine | ||||||||

|

1) The main motor drive the ring die mould rotated. the press roller that were placed inside of the roller does not revolution, but will rotate because the friction of the ring die mould and sawdust wood powder raw material.

2) The biomass wood sawdust powder raw material was spread evenly into the space between the ring die and roller, and was press into the mould hole, formed column shape pellet, the pellet will rotate along with the rotating ring die mould and will be cutted when the length of the column pellet reach to a certain value.

3)Feeder : feeding raw material into the wood pelleting chamber. the feeder is made of stainless steel.

4) Forced feeding unit: since the raw material is fluffy, and the bulking value is higher, we equip the force feeding sets.

5) Pellet making unit: ring die mould and press roller inside work together to make the raw material into wood pellet.

6) Main motor:

driving the pellet making system.

|

||||||||

|

♦ RICHI company was established in 1995. After 26 years of development, has now grown to a feed machinery and engineering,feed pellet production line, food machinery and engineering, steel structure engineering, automatic control technology and engineering; Wood processing machinery and engineer ing , wood pellet production machinery and engineering, biomass energy machinery and engineering. Company has passed the ISO2008 quality management system certification.

♦ Company existing staff 300 people, of which the mechanical design and manufacturing, feed processing technology, electrical automation, computer application, animal science, aquaculture, food engineering, marketing and other kinds of profesional and technical personnel more than 80 people, make our factory has strong market development and sevices, product development and manufactur, project management and delivery capacity.

♦ We have advanced processing and testing equipment, such as large CNC laser cutting machine, large CNC large drilling machine, horizontal boring and milling machine, robot automatic welding machine, coating paint and other advanced production equipment.

♦ Our factory has already successfully finished over 500 turnkey projects. It makes us become one of the most powerful factories of feed and wood pellet machinery. Our factory has already exported our machines to over 83 countries, Such as:United States,Canada,UK, South Africa,Uzbekistan, Afghanistan,Indonesia, Kenya, Australia, Colombia, Brazil , Uruguay, Vietnam, Thailand, Malaysia, Singapore, Indonesia, Algeria, the UAE, Kazakhstan etc. ♦ Welcome to Visit Our Factory! |

MZLH Series Ring Die Pellet Machine - Agro Waste Alfafa Bentonite Cat Litter Bio Fuel Coconut Shell Cotton Hull Pellet Machine