Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/440v/customized

-

Dimension(L*W*H):

-

18*6*4

-

Power (kW):

-

300

-

Weight:

-

5000

-

Screw Speed (rpm):

-

0 - 500 rpm

-

Name:

-

Plastic Granulator Machine

-

Keywords:

-

EVA Shoe Sole Compound Granulating Machine

-

Motor brand:

-

Siemens Beide

-

Inverter brand:

-

ABB/Delta

-

Screw material:

-

W6Mo6Cr4V2

-

Final product:

-

EVA Pellet

-

Processing type:

-

Exturding Machine

-

Raw material:

-

EVA

-

Cutting way:

-

Underwater cutting

-

After-sales Service Provided:

-

Engineers& oversea installation

Quick Details

-

Output (kg/h):

-

600 - 800 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380v/440v/customized

-

Dimension(L*W*H):

-

18*6*4

-

Power (kW):

-

300

-

Weight:

-

5000

-

Screw Speed (rpm):

-

0 - 500 rpm

-

Name:

-

Plastic Granulator Machine

-

Keywords:

-

EVA Shoe Sole Compound Granulating Machine

-

Motor brand:

-

Siemens Beide

-

Inverter brand:

-

ABB/Delta

-

Screw material:

-

W6Mo6Cr4V2

-

Final product:

-

EVA Pellet

-

Processing type:

-

Exturding Machine

-

Raw material:

-

EVA

-

Cutting way:

-

Underwater cutting

-

After-sales Service Provided:

-

Engineers& oversea installation

TPR EVA shoe sole compound extrusion line plastic TPU granules extruder pellet making machine

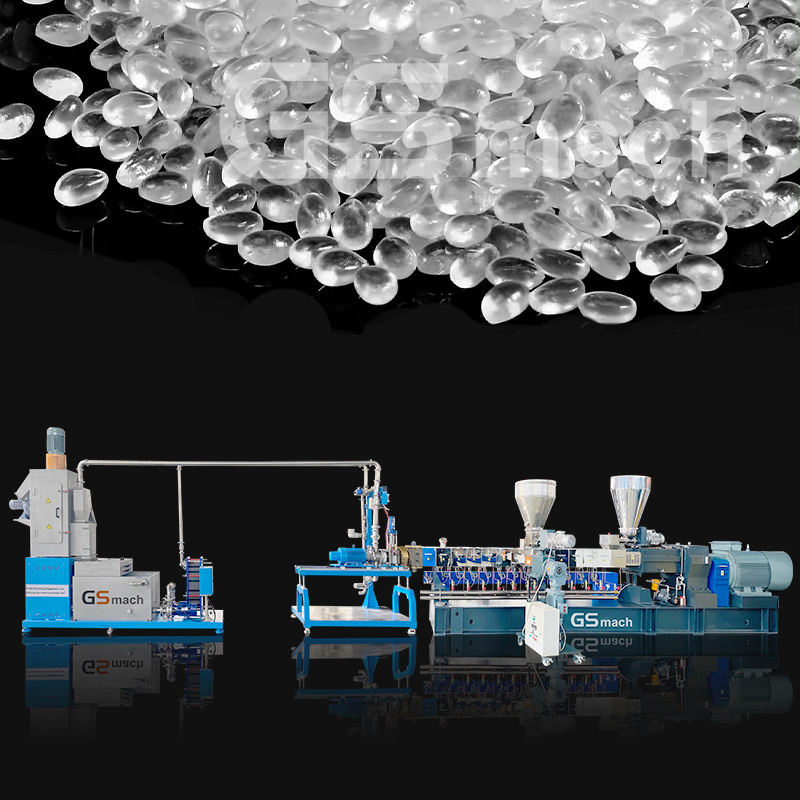

Overall View

EVA (Ethylene-Vinyl Acetate)

is a thermoplastic elastomer material.

EVA material has received widespread attention due to its excellent performance and wide range of applications. Among sole materials, EVA material has good cushioning, shock resistance, anti-slip, wear resistance and other properties, so it is widely used in the manufacturing of various sports shoes, casual shoes and other footwear products.

Main Introduction

TPR EVA shoe sole compound extrusion line plastic TPU granules extruder pellet making machine

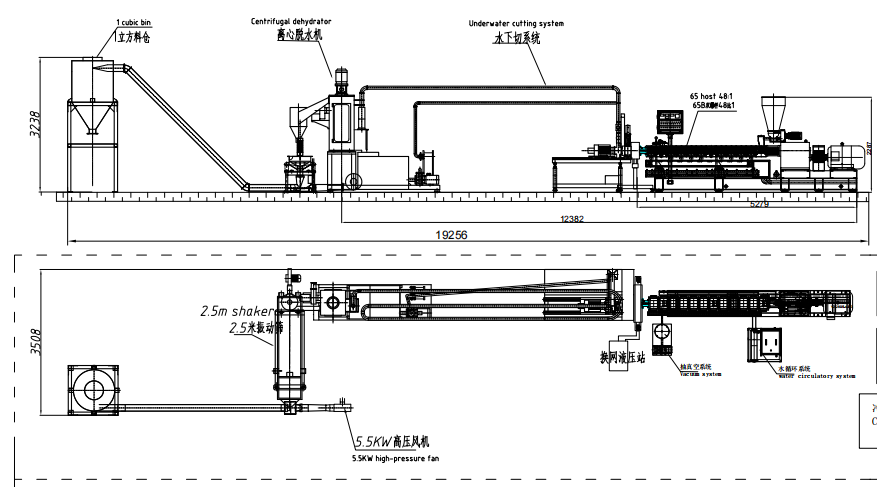

1.Equipment Process Flow

Raw materials------High speed mixer------Twin screw extruder------Underwater pelletizer system------Vibrating screen------Silo

2. Process Flow

After the polymer is heated, sheared, and plasticized, it forms a melt and is extruded. It enters the mold cavity to build pressure and is ejected through a special template designed with optimized and balanced pressure, temperature, and flow distribution. It is placed at the interface of the template. After cutting with a high-speed tool, the particles are separated (this process is continuous and stable). The ejected particles interact with high-pressure cooling water to form spherical or hemispherical regular particles, which are cooled and shaped, and are quickly sent into the pipeline for continuous cooling and then dehydrated and air-dried.

3. Standard Equipment Model

|

Type

|

Screw Dia.

|

Rotate Speed

|

Output(kg/h)

|

Power

|

|

GS50

|

50.5

|

500-600

|

200-300

|

45-90

|

|

GS65

|

62.4

|

500-600

|

400-500

|

75-160

|

|

GS75

|

71

|

500-600

|

600-800

|

110-250

|

|

GS95

|

93

|

400-500

|

1000-1500

|

250-550

|

4. Advantages of the equipment

------Fully automatic continuous production; one-button startup, convenient and fast.

------Shorten the curing time, require less floor space and cooling water, and are energy-saving and environmentally friendly.

------Fully enclosed production, clean environment.

------Low noise & no dust pollution.

5. Layout of the equipment

Details Images

The advantage of underwater pelletizer system is that this method can optimize the

EVA pellets'

shape and make their surface smooth and uniform. The final

EVA granules

have high density and good fluidity. And it can also prevent oxidation of the particles and reduce adhesion.

Application

TPR EVA shoe sole compound extrusion line plastic TPU granules extruder pellet making machine

is with high resilience, tensile strength, and toughness. Soles made of eva materials have good shock-proof and cushioning properties. Nowadays, many sports shoes, basketball shoes, and outdoor travel shoes use eva soles. In addition, EVA soles have very good softness and rubber-like elasticity. Even if the soles are bent, they will not break and have very good wear resistance.

Hot Searches