- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>=99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

China

-

Brand Name:

-

MIC

-

Weight:

-

860 KG

-

Material:

-

Stainless Steel 304/316

-

Name:

-

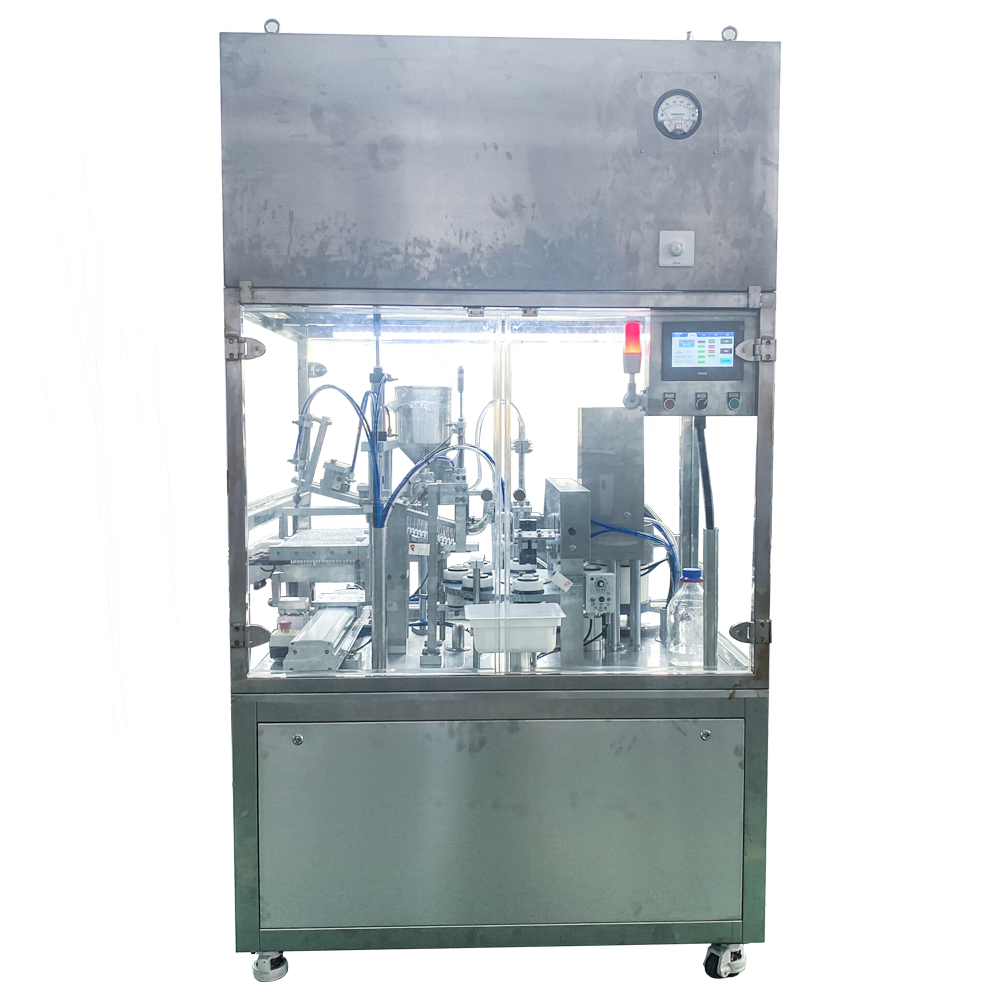

Gel Syringe Filling Machine

-

Function:

-

Vacuum filling plugging

-

Production capacity:

-

1200bph

-

Model:

-

MIC-SGJ-I

-

Filling range:

-

1-10ml

-

Bottle type:

-

Glass Syringe

-

Advantage:

-

Efficiency

-

Suitable for:

-

Gel

-

Control:

-

PLC+ Touch Screen

Quick Details

-

Machinery Capacity:

-

1200bph

-

Packaging Material:

-

Glass, Wood

-

Filling Material:

-

Other

-

Filling Accuracy:

-

>=99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

China

-

Brand Name:

-

MIC

-

Weight:

-

860 KG

-

Material:

-

Stainless Steel 304/316

-

Name:

-

Gel Syringe Filling Machine

-

Function:

-

Vacuum filling plugging

-

Production capacity:

-

1200bph

-

Model:

-

MIC-SGJ-I

-

Filling range:

-

1-10ml

-

Bottle type:

-

Glass Syringe

-

Advantage:

-

Efficiency

-

Suitable for:

-

Gel

-

Control:

-

PLC+ Touch Screen

RELATED PRODUCTS

PRODUCT DESCRIPTION

PRODUCT PARAMETER

|

Filling volume

|

1-20ml

|

|

Filling speed

|

800-1500pieces/hour

|

|

Air consumption

|

0.5Mpa,8m³/h

|

|

Filling accuracy

|

±1%-1.5%

|

|

Power

|

2.5KW,220v 50Hz

|

|

Machine Size

|

1600*1500*1800MM

|

PRODUCT APPLICATION

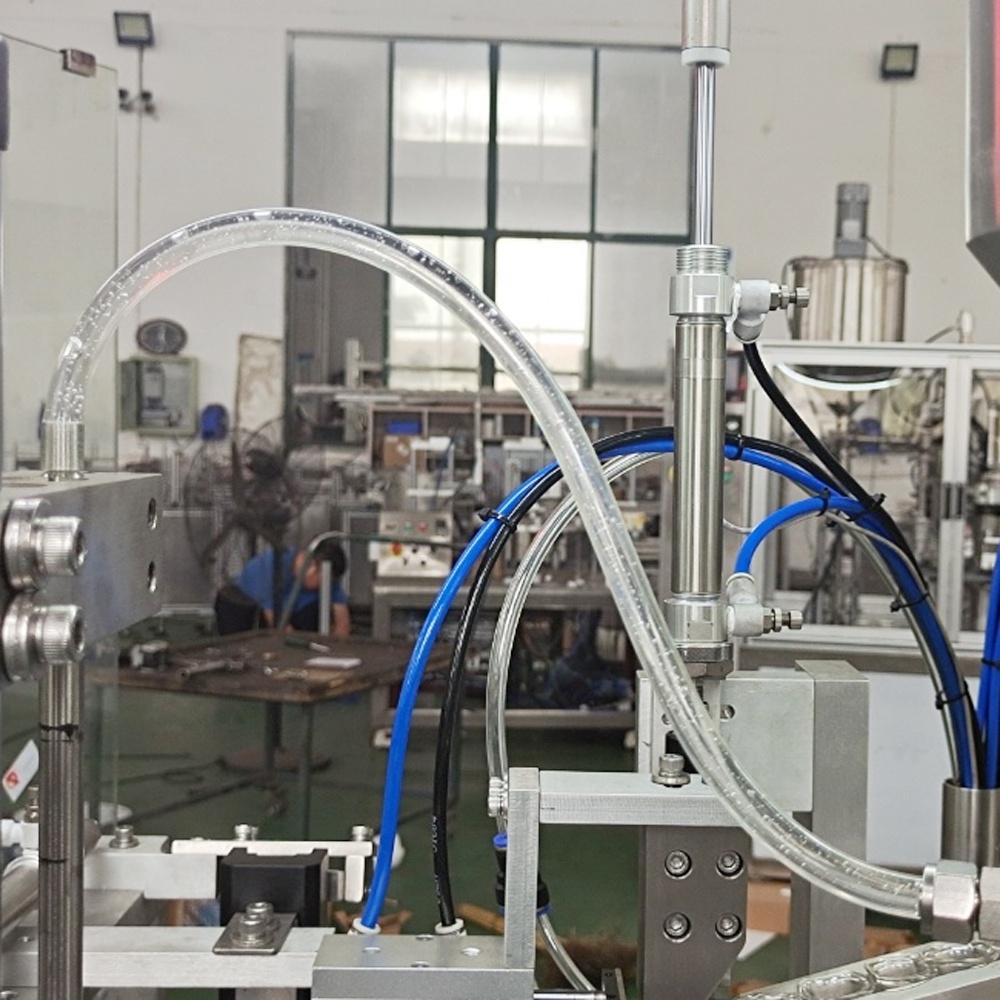

DETAILED IMAGES

Loading syringe tube

Put the syringe honeycomb

on the special fetal membrane

manually

, and hang the syringe on the bottle comb plate together with the fetal membrane at one time, and then automatically enter the filling dial row by row from the slide. The dial rotates intermittently and feeds at a time.

Insert a syringe into the dial wheel and turn it to the corresponding work station.

Filling position

the syringe is brought to the filling station by the dial, a single filling needle is

inserted into the syringe and rises while filling, and the syringe is

sealed at the

same time for vacuum during filling.

The filling pump uses a special gel ceramic pump Filling.

Vacuum stoppering of the syringe

The rubber stopper is arranged by the oscillator.A stopper rod first takes the rubber stopper on the stopper rod On the upper side,

the stopper rod is integrated with a vacuum body,

and at the same time,

the syringe is pressed down to seal and vacuum

, and then the

stopper rod is

added to liquid

level of the syringe.

one set of filling machine has 4sets of

servo motor,

controlled loading tube, filling, filling up and down, sealing.

confirm the machine running stable and high accuracy.

COMPANY INTRODUCTION

FAQ

Hot Searches