- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-415V

-

Dimension(L*W*H):

-

11*5*8

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

38 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1040 mm

-

Mold Platen Size(Height)(mm):

-

1200 mm

-

Air Pressure(MPa):

-

0.65 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

45 kW

-

Accumulator Capacity(L):

-

7.2 L

-

Power (kW):

-

120

-

Weight (T):

-

12

-

color:

-

as requirement

-

average power:

-

150kw

-

thickness control:

-

MOog

-

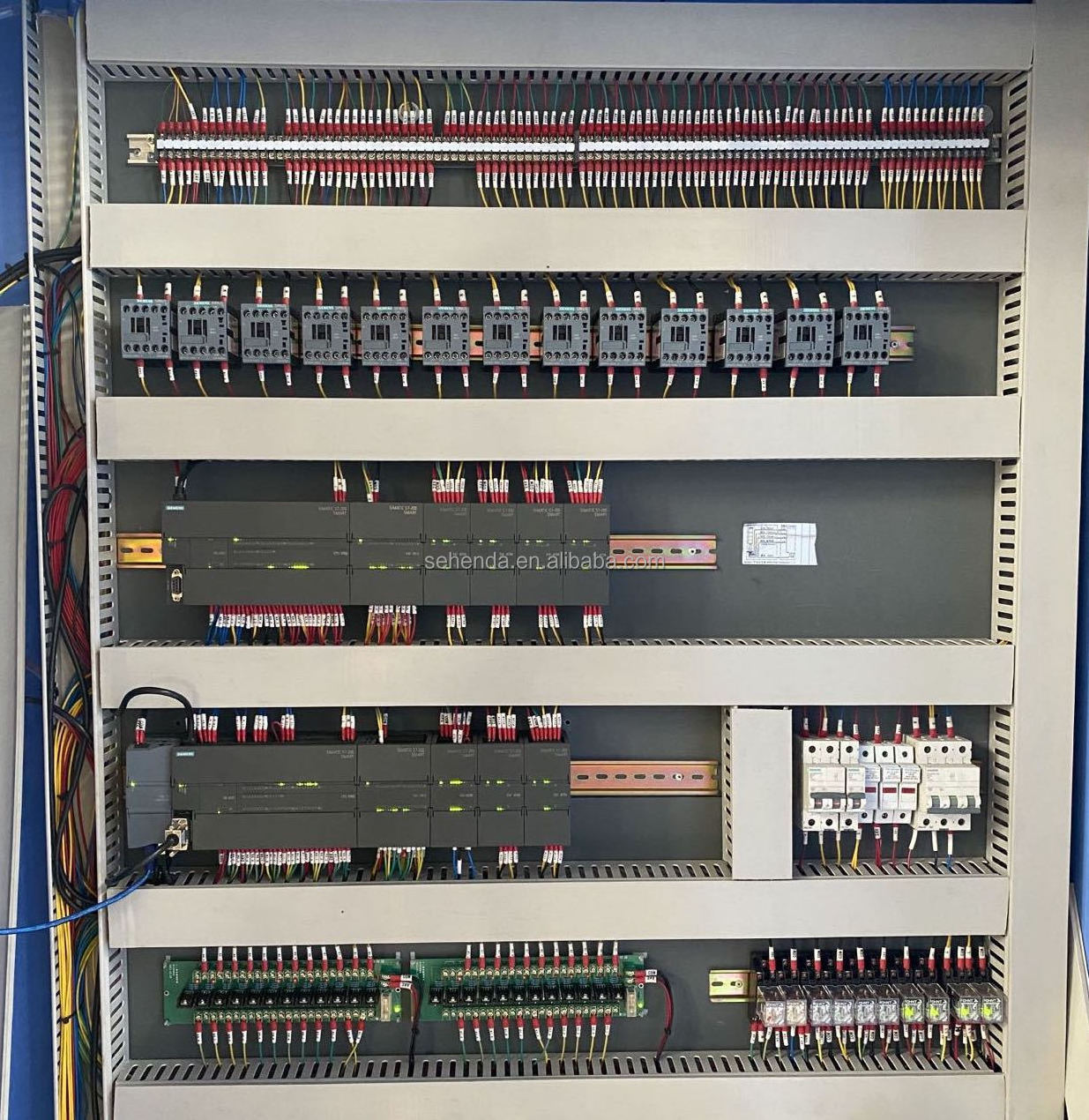

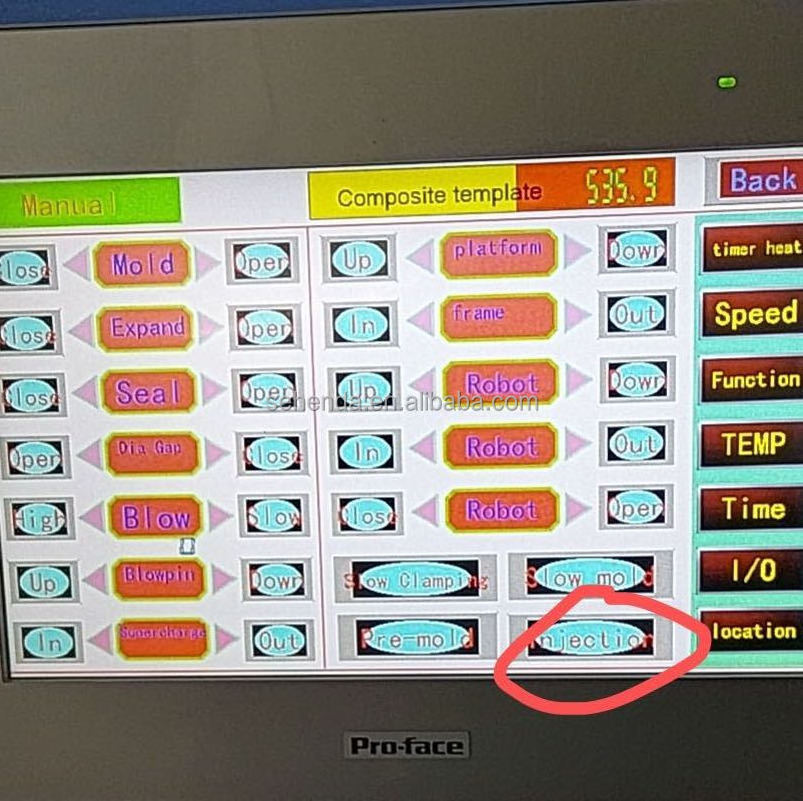

PLC:

-

seimens

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

Quick Details

-

Clamping Force (kN):

-

1800

-

Output (kg/h):

-

180 kg/h

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380-415V

-

Dimension(L*W*H):

-

11*5*8

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

38 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1040 mm

-

Mold Platen Size(Height)(mm):

-

1200 mm

-

Air Pressure(MPa):

-

0.65 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

45 kW

-

Accumulator Capacity(L):

-

7.2 L

-

Power (kW):

-

120

-

Weight (T):

-

12

-

color:

-

as requirement

-

average power:

-

150kw

-

thickness control:

-

MOog

-

PLC:

-

seimens

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

drum blow molding machine

Automatic blow moulding machine for drums barrels gallons

55 gallon drum blow molding machine

SKJ120(single station single die head)

automatic blow moulding machine was specially designed for making plastic water tanks,plastic cans, lubricant oil bottles,plastic drums and other plastic containers not over 250L.

1. Appliction : For container and tank from 120 to 250 liter, 1-2 layer

, also can be used to produce pallet, waste bin, road barrier, septictank,and so on.

2. Manpower : 2 new workers are enough for the whole production line, even both are female, and two weeks training are free of charge.

3. Output : 20pcs for 200L 3 layer tank per hour the weight and thickness can be adjusted by you from 1mm to 10 mm.

4. Material : PE ,HDPE

5. Main Markets : Asia, South Amereica, European.

6 .Delivery time : 3 months

7 .Advantage:

1.Our company has been producing Blow molding machine for more than 13 years. We accumulate profound experience of design and ma nufacturing.

2. We have export blowing molding machines for 3 years i.e. India, German, Italy, New Zealand, Peru, Thailand, Malaysia and so on and receives a highly reputation.

3.There is a complete after-sale service system form installation to training.

4.We could design various molds and also customize strange-shaped hollow products.

8. Guarantee time: 1 year . During guarantee period if some parts of the machine are damaged or broken or there are some problems on the machine (except Artificial damage ), The Seller will change or fix that free of charge.

9. Certificate: CE , ISO9001:2008.

10. Installation:

a) The Seller will dispatch an engineer and translator against the requests of the Buyer to install and adjust the machine for 10 days in the Buyer ’ s factory.

b) The Buyer need to inform the Seller 15 days in advance.

c)The Buyer should pay for the engineer and translator ’ s visa application cost, round- tickets, food & accommodation before their departure.

11. Training:

The Buyer could dispatch their operators to the Seller ’ s factory for training, including machine operation, maintenance & repair; Or against the requests of the Buyer, the Seller ’ s technician could train the Buyer ’ s operators in the Buyer ’ s factory during the period of installation & adjusting; The training is free of charge.

12. Package:

Container transport to Qingdao port China, container size and quantity according to the machine and other goods.

Important parts in box; Parts,easy to rust,antirust

encapsulation; Other parts fixed in container

20

years specializing in manufacturing huge blow moulding machine worth your trust .

years specializing in manufacturing huge blow moulding machine worth your trust .

For more details? Pls contact us.

Main unit of blow moulding machine

| LOW-VOLTAGE APPARATUS | LG | KOREA |

| PNEMATIV | AIRTAC | TAIWAN |

| HYDRAULIC COMPONENT | YUKEN | LAPAN |

| SEAL | DICHT0MATIK | GERMANY |

| OIL MOTOR | SIEMENS | |

| SCREW MOTOR | SINMENS | |

| PROXIMITY SWITCH | OMRON | JAPAN |

| PLC | MITSTUBLISH | |

| TOUCH SCREEN | WEINVIEW | TIAWAN |

| WALL THINKNESS CONTRAL SYSTEM | MOOG | JAPAN |

| FREQUENCY CONVERTERS | ABB/LG/MITSUBISH |