- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FRP grating

-

Model Number:

-

frp composite grating

-

Surface Treatment:

-

anti-slip

-

Material:

-

FRP

-

Open area:

-

40% 80%

Quick Details

-

Application:

-

FRP grating walkway

-

Technique:

-

pultruded

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FRP grating

-

Model Number:

-

frp composite grating

-

Surface Treatment:

-

anti-slip

-

Material:

-

FRP

-

Open area:

-

40% 80%

Products Description

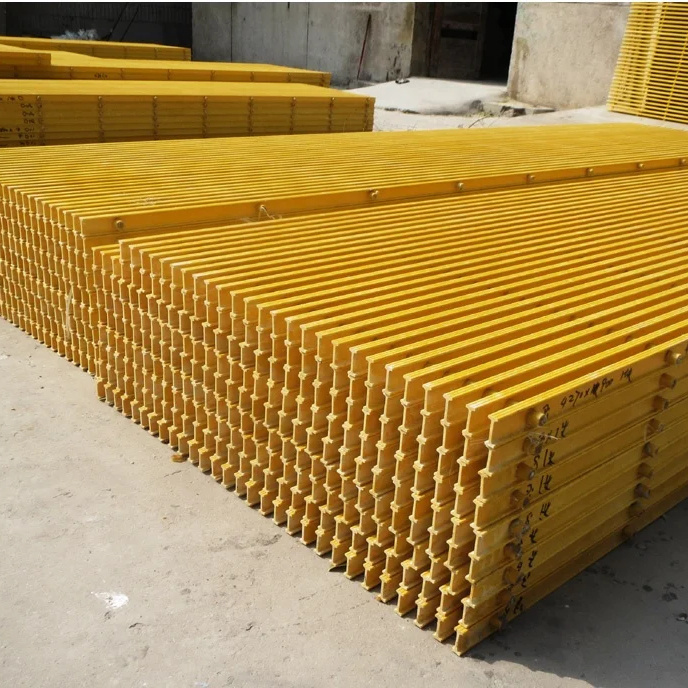

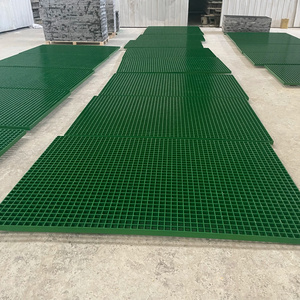

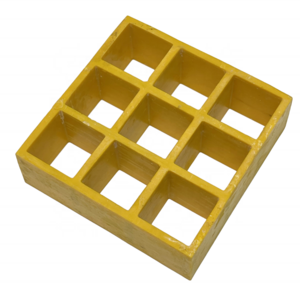

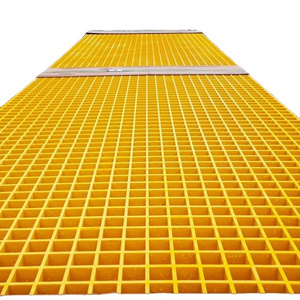

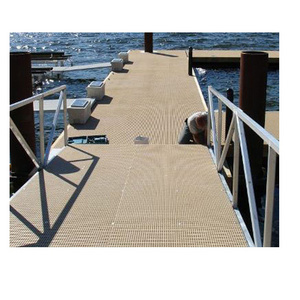

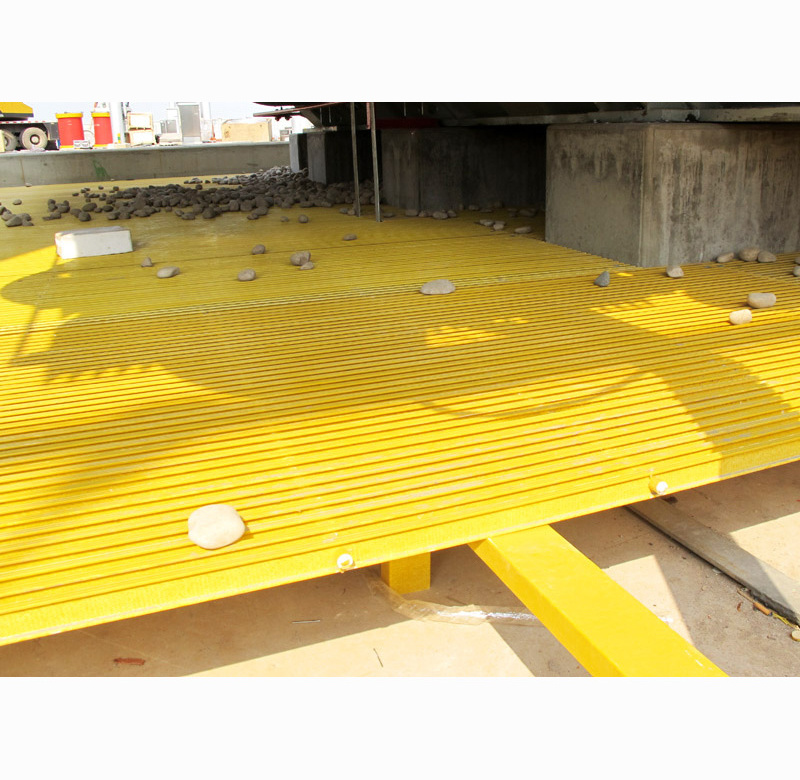

Pultruded fiberglass grating materials are oftentimes used for walkways, sun-screens, decking, docks, ramps, and other public structures

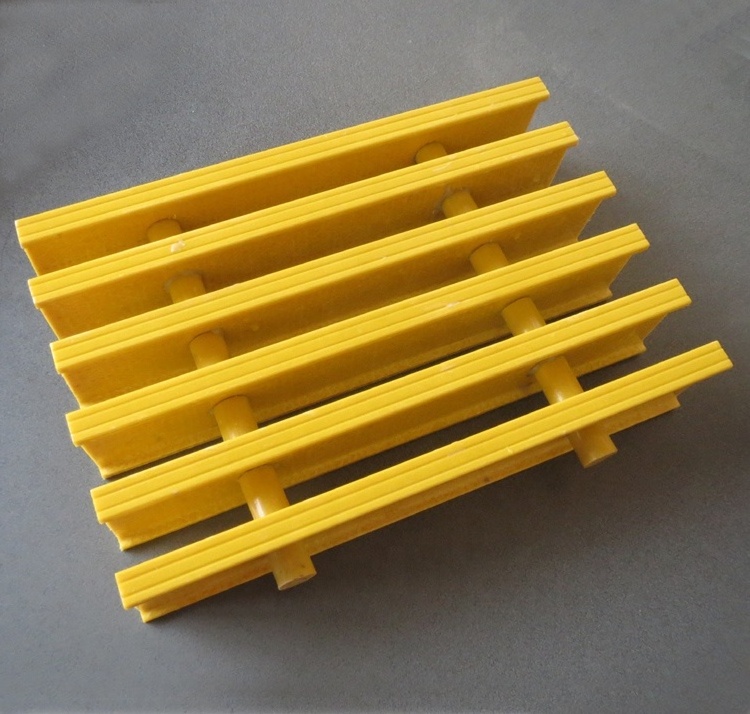

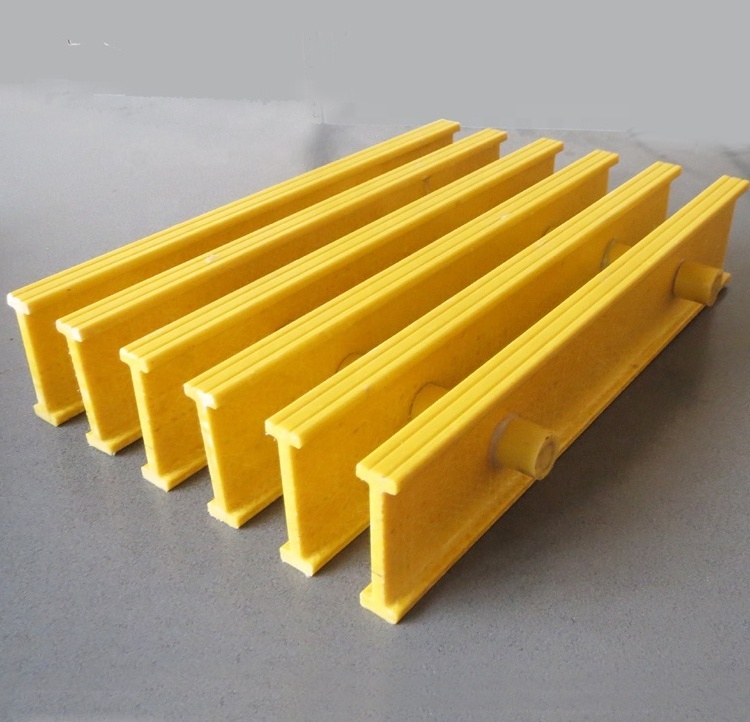

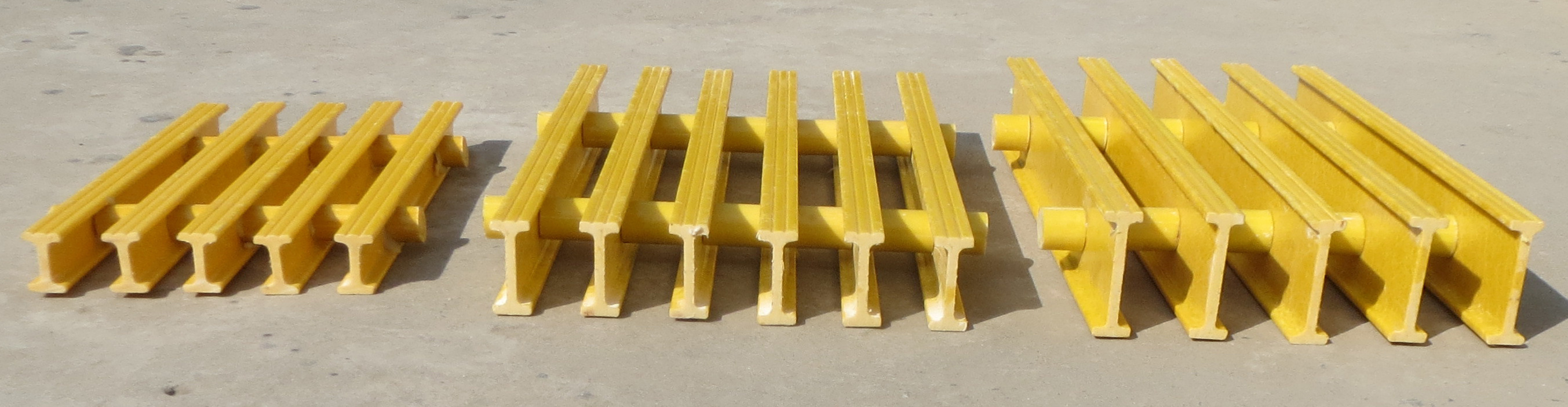

1- manufactured by assembly of pultruded I-Beam & pultruded cross roads. The distance between I-Beam & cross roads depend upon various load conditions.

2 5mm,38mm, 40mm, 50mm,58mm,65mm high grating are available;

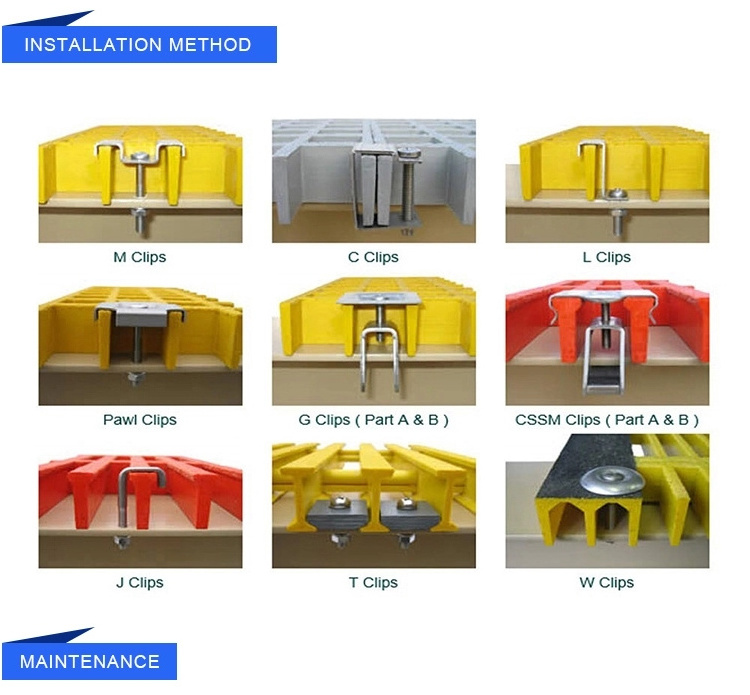

3-Easy to install;

4-Can be cut at any lengths you need; open area is decided by customer

5-Grating clamps are available.

1- manufactured by assembly of pultruded I-Beam & pultruded cross roads. The distance between I-Beam & cross roads depend upon various load conditions.

2 5mm,38mm, 40mm, 50mm,58mm,65mm high grating are available;

3-Easy to install;

4-Can be cut at any lengths you need; open area is decided by customer

5-Grating clamps are available.

Fiberglass pultruded grating advantages:

1. High Strength : Fiberglass pultruded grating exhibits outstanding strength, capable of bearing significant loads, making it suitable for applications with high strength requirements.

2. Lightweight Design : Compared to traditional metal gratings, fiberglass pultruded grating is lightweight, facilitating easier installation and maintenance and reducing the overall burden on the structure.

3. Corrosion Resistance: Fiberglass possesses excellent corrosion resistance, making pultruded grating resistant to harsh environments, including humidity, chemicals, and salt spray, thereby extending its service life.

4. Insulation Properties: Fiberglass is a non-conductive material, providing excellent electrical insulation. This feature is beneficial in applications where electrical insulation is required.

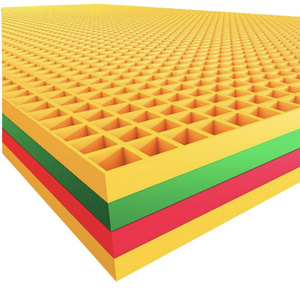

5. Customizability : Fiberglass pultruded grating can be customized to meet specific requirements, including different sizes, colors, and shapes, allowing adaptation to various design specifications.

6. Low Maintenance Costs: Due to its corrosion resistance and aging resistance, fiberglass pultruded grating typically requires minimal maintenance, reducing overall maintenance costs and frequency.

1. High Strength : Fiberglass pultruded grating exhibits outstanding strength, capable of bearing significant loads, making it suitable for applications with high strength requirements.

2. Lightweight Design : Compared to traditional metal gratings, fiberglass pultruded grating is lightweight, facilitating easier installation and maintenance and reducing the overall burden on the structure.

3. Corrosion Resistance: Fiberglass possesses excellent corrosion resistance, making pultruded grating resistant to harsh environments, including humidity, chemicals, and salt spray, thereby extending its service life.

4. Insulation Properties: Fiberglass is a non-conductive material, providing excellent electrical insulation. This feature is beneficial in applications where electrical insulation is required.

5. Customizability : Fiberglass pultruded grating can be customized to meet specific requirements, including different sizes, colors, and shapes, allowing adaptation to various design specifications.

6. Low Maintenance Costs: Due to its corrosion resistance and aging resistance, fiberglass pultruded grating typically requires minimal maintenance, reducing overall maintenance costs and frequency.

Pultruded grating superior features compare with molded grating

1. Corrosion resistant: resist most acids, caustics and salts

2. Strength: 2 to 3 times stronger than molded grating, suitable for wide support span, carry great load bearing

3. Impact resistance: The 65% glass to 35% resin ratio of pultruded grating provides twice the stiffness of molded grating, high ultimate strength prevents impact damage

Pultruded grating superior features compare with steel grating

* Corrosion resistant: resists most acid, caustics and salts

* Safety: low electrical conductivity, non-skid surface

* Lightweight: 1/3 the weight of steel

* Easy for transport and filed fabricated

1. Corrosion resistant: resist most acids, caustics and salts

2. Strength: 2 to 3 times stronger than molded grating, suitable for wide support span, carry great load bearing

3. Impact resistance: The 65% glass to 35% resin ratio of pultruded grating provides twice the stiffness of molded grating, high ultimate strength prevents impact damage

Pultruded grating superior features compare with steel grating

* Corrosion resistant: resists most acid, caustics and salts

* Safety: low electrical conductivity, non-skid surface

* Lightweight: 1/3 the weight of steel

* Easy for transport and filed fabricated

FRP grating applications:

* FRP Stair and Handrail systems

* Industrial platforms and walkways

* Marine structures

* Food Manufacturing Applications

* Fiberglass Baffle Walls

* Manhole Covers

* Fiberglass Louvers and Ridge Vents

* Ladder systems

* FRP Tank Covers

* Water & Wastewater Containment systems

* Sludge Dry Beds

* Trough Covers

* FRP Enclosures

* FRP ramps and crossovers

* Industrial platforms and walkways

* Marine structures

* Food Manufacturing Applications

* Fiberglass Baffle Walls

* Manhole Covers

* Fiberglass Louvers and Ridge Vents

* Ladder systems

* FRP Tank Covers

* Water & Wastewater Containment systems

* Sludge Dry Beds

* Trough Covers

* FRP Enclosures

* FRP ramps and crossovers

Chemical plant FRP grating trench drain cover

Chemical plant FRP grating walkway

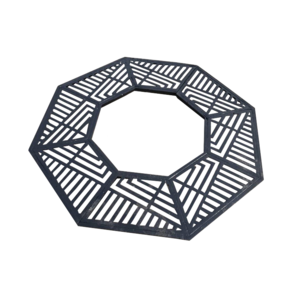

FRP grating air conditioner screen

FRP grating for transformer substation

FRP grating walkway for ship decking

FRP grating stair step

Product Paramenters

Pultruded FRP grating specification list

the open area of pultruded FRP grating dimensions could be adjusted as requirement, below is popular size list

|

Art No.

|

“I”high A

(mm) |

“I"Top width B

(mm) |

"I" bottom width D (mm)

|

clearance C

(mm) |

open area

|

approx weight

(kg/sqm) |

|

5025

|

25

|

30

|

30

|

30

|

50

|

10

|

|

4025

|

25

|

15

|

15

|

10

|

40

|

13.8

|

|

5025

|

25

|

15

|

15

|

15

|

50

|

11.9

|

|

6025

|

25

|

15

|

15

|

23

|

60

|

10

|

|

4038

|

38

|

15

|

15

|

10

|

40

|

20.5

|

|

5038

|

38

|

15

|

15

|

15

|

50

|

17.8

|

|

6038

|

38

|

15

|

15

|

23

|

60

|

14.8

|

|

6038ii

|

38

|

15

|

15

|

23

|

60

|

19.2

|

|

4040

|

40

|

40

|

20

|

27

|

40

|

19.5

|

|

5040

|

40

|

40

|

20

|

40

|

50

|

17

|

|

6040

|

40

|

40

|

20

|

60

|

60

|

14

|

|

4040i

|

40

|

30

|

30

|

20

|

40

|

14

|

|

5040i

|

40

|

30

|

30

|

30

|

50

|

12

|

|

6040i

|

40

|

30

|

30

|

45

|

60

|

10

|

|

6050

|

50

|

15

|

15

|

23

|

60

|

16

|

|

5050

|

50

|

15

|

15

|

15

|

50

|

22.5

|

|

4050

|

50

|

15

|

15

|

10

|

40

|

25.5

|

|

4058

|

58

|

15

|

15

|

10

|

40

|

32

|

|

5058

|

58

|

15

|

15

|

15

|

50

|

27

|

|

6058

|

58

|

15

|

15

|

23

|

60

|

22

|

|

4065

|

65

|

30

|

30

|

20

|

40

|

17

|

|

5065

|

65

|

30

|

30

|

30

|

50

|

15

|

|

6060

|

60

|

30

|

30

|

45

|

60

|

12

|

the structure of 4025 FRP grating

the clearance and crossbar distance could be adjusted

Packing And Shipping

Packing type:

pallets, wood carton, etc. also could packing according to customer's requirement.

Shipping:

land shipping, air shipping, railway shipping, express delivery(length can't over 2.5m)

Hot Searches