Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SG001

-

Brand Name:

-

SYGO

-

Product Type:

-

Custom Injection Molded Plastic Parts

-

Material:

-

Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

-

Process:

-

Cnc Machining+Deburrs

-

Tolerance:

-

±0.01mm to ±0.005mm

-

Certificates:

-

ISO9001:2015

-

Equipment:

-

CNC Machining Center,CNC lathe,CNC turning,milling

-

Feature:

-

Precision Durable

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

Color:

-

Customized Color

-

Our service:

-

OEM & ODM service

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

SG001

-

Brand Name:

-

SYGO

-

Product Type:

-

Custom Injection Molded Plastic Parts

-

Material:

-

Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

-

Process:

-

Cnc Machining+Deburrs

-

Tolerance:

-

±0.01mm to ±0.005mm

-

Certificates:

-

ISO9001:2015

-

Equipment:

-

CNC Machining Center,CNC lathe,CNC turning,milling

-

Feature:

-

Precision Durable

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

Color:

-

Customized Color

-

Our service:

-

OEM & ODM service

Products Description

|

Product Processing Type

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection

Molding |

|

|

|

|||

|

Materials

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc.

|

|

|

|

|||

|

|

Stainless steel: SUS303, SUS304, SS316, SS316L, 412,201,202,17-4PH, etc.

|

|

|

|

|||

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|

|

|

|||

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|

|

|

|||

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

|

|

|

|

|||

|

|

Other Materials Are Available

|

|

|

|

|||

|

Certification

|

ISO9001,IATF,SGS

|

|

|

|

|||

|

Drawing Format

|

PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF

|

|

|

|

|||

|

Surface Treatment

|

Anodizing, Polishing, Powder coating, Passivation, Sandblasting, Nickal plating,Zinc plating, Chrome plating, Heat treatment,

Oxidation |

|

|

|

|||

|

Tolerance丨Surface Roughness

|

±0.002 ~ ±0.005mm,Ra0.2 - Ra3.2(Custonize avaiable)

|

|

|

|

|||

|

Testing Equipment

|

Cmm/Tool Microscope/Multi-Joint Arm/Automatic Height Gauge/Manual Height Gauge/Dial Gauge/Roughness Measurement

|

|

|

|

|||

|

Application

|

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications

|

|

|

|

|||

|

Our Advantages

|

1.24 hours online service & Quickly Quote/Delivery.

2.100% QC quality inspection before delivery, and can provide qualityinspection form.

3.20+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions.

|

|

|

|

|||

|

Color

|

Customized

|

|

|

|

|||

|

OEM

|

Accept

|

|

|

|

|||

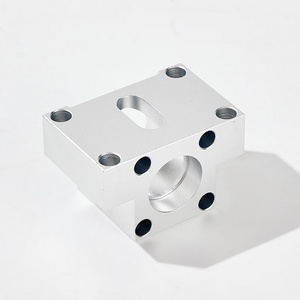

Processed Material

Machining Aluminum Parts

Material:

2024,5052,5083,6061,6061-T6, 6063,6082,7075,etc.

Tolerance:

+/- 0.01~0.005mm

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Machining Stainless Steel / Steel Parts

Material:

SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance:

+/- 0.01~0.005mm

Surface treatment:

electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc.

Machining Brass / Copper / Bronze Parts

Material:

HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Tolerance:

+/- 0.01~0.005mm

Surface treatment:

electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

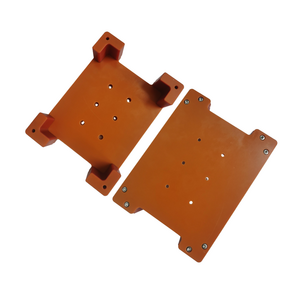

Machining Plastic Parts

Material:

Acetal/POM/PA/Nylon/PC/PMMA/PP/PVC/PU/HDPE/PVDF/Acrylic/ABS/PTFE/PEEK etc.

Tolerance:

+/- 0.01~0.005mm

Surface treatment:

spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing,engraving, etc.

Surface Treatment

Test equipment

Our Partner

Factory Show

Packaging & Shipping

FAQ

1. Are you a manufacturer or a trading company?

We are a 3500-square-meter factory located in zhejiang, China.

2. How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4. Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Hot Searches