- Product Details

- {{item.text}}

Quick Details

-

Material:

-

WC+Co

-

Size:

-

Cusomized

-

Type:

-

Woodworking Turning Tools

-

MOQ:

-

1 Piece

-

Certification:

-

ISO 9001

-

Length:

-

10~335mm

-

Hardness:

-

HRA87 - HRA93.5

-

Application:

-

Cutting

-

Density:

-

14.15~19 g/cm3

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Burray

-

Product name:

-

Carbide Bar&Rod

-

Material:

-

WC+Co

-

Size:

-

Cusomized

-

Type:

-

Woodworking Turning Tools

-

MOQ:

-

1 Piece

-

Certification:

-

ISO 9001

-

Length:

-

10~335mm

-

Hardness:

-

HRA87 - HRA93.5

-

Application:

-

Cutting

-

Density:

-

14.15~19 g/cm3

Stock Polished Cemented Tungsten Carbide Rods

Carbide rods belong to carbide cutting tools, stable performance, easy welding, wear resistance, impact resistance. Carbide rods are mainly suitable for drills, end mills and reamers.

Carbide rods belong to carbide cutting tools, stable performance, easy welding, wear resistance, impact resistance. Carbide rods are mainly suitable for drills, end mills and reamers.

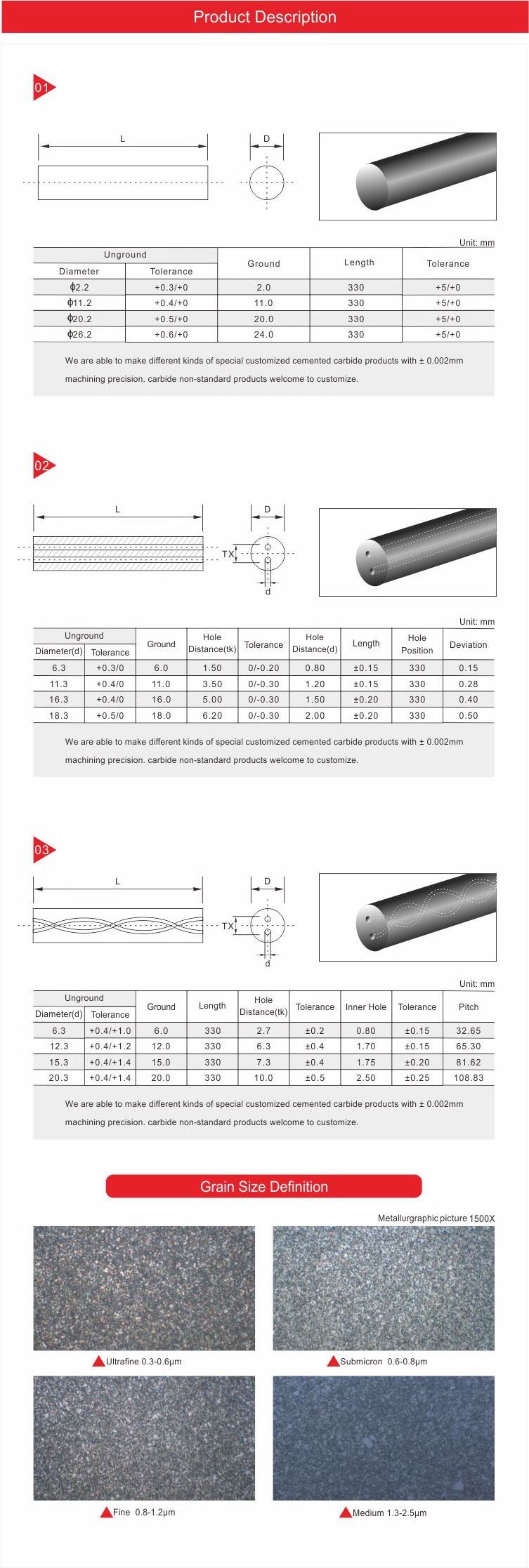

| ISO | Grain Size μm | Density g/cm3 | Hardness HRA | T.R.S N/mm2 |

Cobalt Comtent(WT. %) |

| k20 | Ultrafine | 14.6 | 93.2 | 3300 | 8.0 |

| k30 | Ultrafine | 14.35 | 92.6 | 3600 | 10.0 |

| k40 | Ultrafine | 14.15 | 92.3 | 3900 | 12.0 |

| k10 | Submicron | 14.9 | 93.6 | 2600 | 6.0 |

| k25 | Fine | 12.0 | 92.5 | 2200 | 9.0 |

| k35 | Fine | 11.5 | 90.5 | 2300 | 12.0 |

| k30 | Medium | 14.6 | 89.9 | 2350 | 9.0 |

| k40 | Medium | 14.2 | 88.8 | 2600 | 12.0 |

Workers and techniques from Burray, have over 10 years of professional experience in the carbide rotary burrs; Our Carbide produces all of the carbide covered by the industry standards as well as custom grades to meet special customer requirements. The professional sales team and after-sale service in carbide rotary burrs; We can provide an overall solution and select the most suitable carbide rotary burrs according to your application.

1.Direct factory sale.

2.Reasonable price.

3.good wear resistance.

4.Longer service life.

5.OEM service available.

6.Short and on time delivery.

7.Samples and small orders are acceptable.

Every part is carefully processed (by grinding, machining, milling, wire-cutting, EDM etc) to the exact tolerances shown on the drawing and carefully checked both in production line and QC room (QC check every dimension of every part before packing and shipping). In this way, we assured the high precision and thus the interchangeability in the tool room of the customers’ factory.

1.Plastic case filling sponges, and foam. cotained in wooden/carton case.

2.Special packaging according to clients' requirments.

3.Shipping: Shenzhen, Chongqing, Shanghai, Qingdao, Guangzhou, etc. We accept land, air, sea transport and international multimodal transport.