- Product Details

- {{item.text}}

Quick Details

-

color:

-

various color Polyphthalamide Resin

-

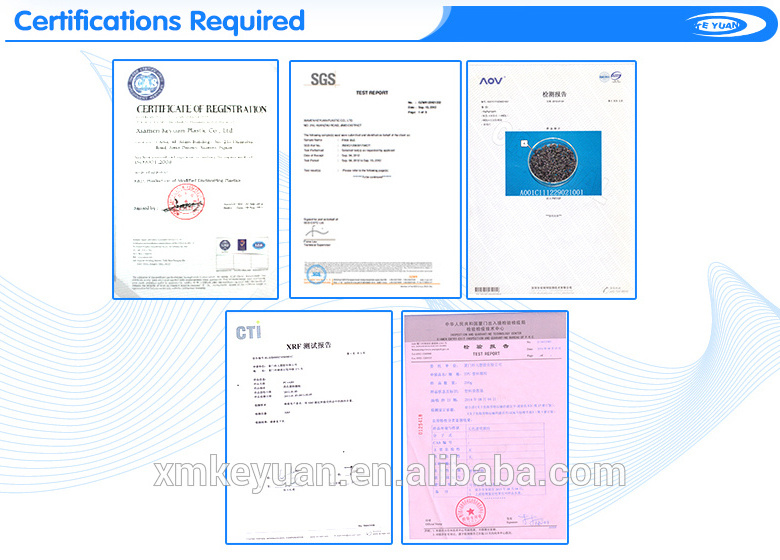

certificate:

-

ISO/SGS/RHOS

-

brand name:

-

keyuan: PPA Plastic Granule

-

Certification:

-

RoHS

-

Material:

-

PPA/PPO/PA612

-

Type:

-

Virgin/Recycled

-

Grade:

-

Injection Moulding

-

sample:

-

free sample

-

Shape:

-

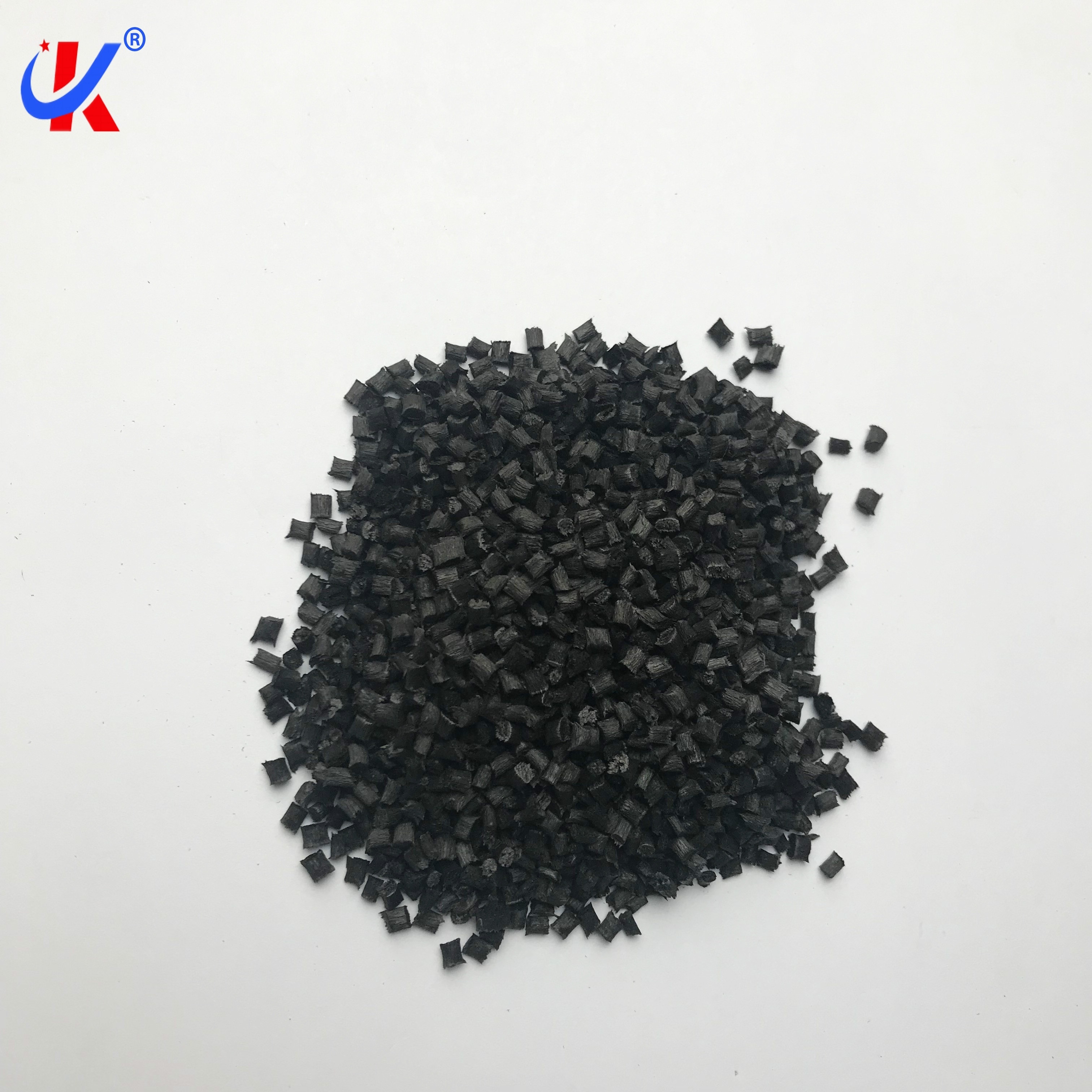

Polyphthalamide PPA granules

-

Feature:

-

PPA GF20%/GF33%

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

KEYUAN

-

Model Number:

-

KY-T6602

-

color:

-

various color Polyphthalamide Resin

-

certificate:

-

ISO/SGS/RHOS

-

brand name:

-

keyuan: PPA Plastic Granule

-

Certification:

-

RoHS

-

Material:

-

PPA/PPO/PA612

-

Type:

-

Virgin/Recycled

-

Grade:

-

Injection Moulding

-

sample:

-

free sample

-

Shape:

-

Polyphthalamide PPA granules

-

Feature:

-

PPA GF20%/GF33%

PPA GF33% Plastic Material Resin Glass Fiber / Carbon Fiber Reinforced CF20% CF33% Polyphthalamide PPA Polymer

Advantage:

1. temperature: continuous use temperatures up to 170 ℃, heat distortion temperature of 280 ℃ (1.8MPa) or higher;

2. good mechanical strength: a strength as aluminum, steel, stiffness;

3. high liquidity, low touch temperature injection molding, high weld line strength, better than the LCP material, cracking problem can be solved;

4. superior chemical resistance, can withstand particular ethylene glycol and water erosion;

5. dimensional stability, low water absorption, anti-warping.

Polyphthalamide PPA Application:

1.Electronic and Electrical Area:

Various connectors connectors, memory cards, laptop memory, backplane, LED packaging, circuit breakers, motor parts, switch components, etc.;

2.auto industry:

Engine peripheral components, such as the filter, the engine cover, Valve and pump housing.

| Property item | Test condition | Test method | PPA | Unit | |

| Physical properties | Specific gravity | ASTM D792 | 1.45 | ||

| Water absorption rate | ASTM D570 | 0.15 | % | ||

| Mould contraction rate | 3.2mm | ASTM D955 | 0.3-0.8 | % | |

| Melt idex | ASTM D1238 | 7 | g/10min | ||

| Mechanical properites | Tensile strength (yield point) | ASTM D638 | 145 | Mpa | |

| Tensile modulus | ASTM D638 | 12000 | Mpa | ||

| Tensile rate (rupture point) | ASTM D638 | 2 | % | ||

| Flexural yield strength | ASTM D790 | 225 | Mpa | ||

| Flexural modulus | ASTM D790 | 11000 | Mpa | ||

| Impact strength (notched) | 23 ℃ | ASTM D256 | 80 | J/m | |

| Hardness | Rockwell | ASTM D785 | 121 | R | |

| Heat deflection temperature HDT/A | 1.8Mpa | ASTM D648 | 300 | ℃ | |

| Linear Expansibility | E831 | 0.0002 | 1/ ℃ | ||

| Inflaming reatarding | 0.5mm | UL94 | 5VA | ||

| Electrical properties | Dissipation factor | 100Hz | ASTM D150 | 3.78 | |

| Dissipation factor | 1MHz | ASTM D150 | 3.53 | ||

| Permittivity | 100Hz | ASTM D150 | 0.005 | ||

| Permittivity | 1MHz | ASTM D150 | 0.012 | ||

| (Ohm-cm) Volume residtivity | ASTM D257 | 1.3E+16 | Ω-cm | ||