- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Gosunm

-

Weight:

-

80 KG

-

Machinery Capacity:

-

60-200pcs/min (depends on the label size)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

shrink label tunnel sleeve labeling machine, sleeve labeling machine

-

Usage:

-

bottle single labeling

-

Applicable Dimensions:

-

plastic and film

-

Label speed:

-

15-160pcs/min

-

Labeling accuracy:

-

1.0mm

-

Labeling speed (pcs / min):

-

labeling for soft tube

-

Weight (kg ):

-

semi-automatic soft tube self ahesive sticker labeling machine

-

Frequency (HZ):

-

effective labeling for soft tube

-

Applicable Label width ( width ):

-

soft tube labeling machine

Quick Details

-

Application:

-

APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles, petrified

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Gosunm

-

Weight:

-

80 KG

-

Machinery Capacity:

-

60-200pcs/min (depends on the label size)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

shrink label tunnel sleeve labeling machine, sleeve labeling machine

-

Usage:

-

bottle single labeling

-

Applicable Dimensions:

-

plastic and film

-

Label speed:

-

15-160pcs/min

-

Labeling accuracy:

-

1.0mm

-

Labeling speed (pcs / min):

-

labeling for soft tube

-

Weight (kg ):

-

semi-automatic soft tube self ahesive sticker labeling machine

-

Frequency (HZ):

-

effective labeling for soft tube

-

Applicable Label width ( width ):

-

soft tube labeling machine

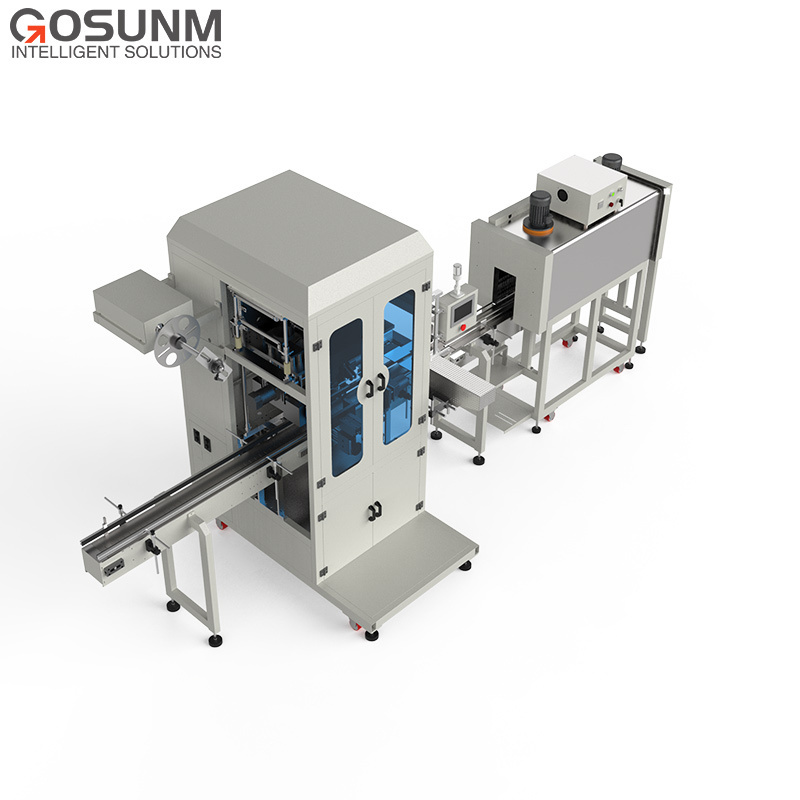

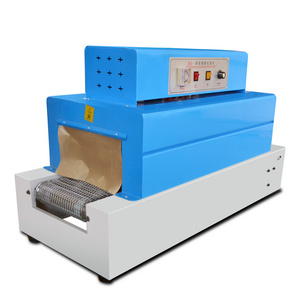

Shrink Sleeve Labeling Machine

with Electric Heater Shrinking Tunnel

|

Specifications

|

|

|

|

Model

|

GST-250E

|

|

|

Production Capacity

|

≥12000BPH

|

|

|

Qualified Rate

|

≥99.9%

|

|

|

Production Efficiency Of The Whole Line

|

≥95%

|

|

|

Bottle Diameter

|

50mm ~95mm

|

|

|

Bottle Height

|

30 mm -280 mm

|

|

|

Bottle Verticality

|

≤1. 0°

|

|

|

Applicable Labels

|

PVC、PET、OPS

|

|

|

Label Length

|

30mm ~250mm

|

|

|

Label Thickness

|

0.027mm ~0.13mm

|

|

|

Label Material

|

PVC、PET、OPS

|

|

|

Label Clear Pitch

|

≥5mm

|

|

|

Inner Diameter Of Roll Label Core

|

≥4”(76mm)

|

|

|

Outer Diameter Of Roll Label

|

≤500mm

|

|

|

Voltage

|

220V

|

|

|

Sleeve Labeling Machine Power

|

3.5KW

|

|

|

Main Machine Size

|

2000X1050X2100mm

|

|

|

Weight Of The Whole Machine

|

300 kg

|

|

Machine Details

Shrink Sleeve Labeling Machine

with Steam Shrinking Tunnel

|

Specifications

|

|

|

|

|

||||

|

Model

|

|

|

GST-250S

|

|

||||

|

Production Capacity

|

|

|

≥20000BPH

|

|

||||

|

Qualified Rate

|

|

|

≥99.9%

|

|

||||

|

Production Efficiency Of The Whole Line

|

|

|

≥95%

|

|

||||

|

Bottle Diameter

|

|

|

50mm~95mm

|

|

||||

|

Bottle Height

|

|

|

30 mm -280 mm

|

|

||||

|

Bottle Verticality

|

|

|

≤1. 0°

|

|

||||

|

Applicable Labels

|

|

|

PVC、PET、OPS

|

|

||||

|

Label Length

|

|

|

30mm ~250mm

|

|

||||

|

Label Thickness

|

|

|

0.027mm ~0.13mm

|

|

||||

|

Label Material

|

|

|

PVC、PET、OPS

|

|

||||

|

Label Clear Pitch

|

|

|

≥5mm

|

|

||||

|

Inner Diameter Of Roll Label Core

|

|

|

≥4”(76mm)

|

|

||||

|

Outer Diameter Of Roll Label

|

|

|

≤500mm

|

|

||||

|

Voltage

|

|

|

220V

|

|

||||

|

Sleeve Labeling Machine Power

|

|

|

3.5KW

|

|

||||

|

Main Machine Size

|

|

|

2000X1050X2100mm

|

|

||||

|

Weight Of The Whole Machine

|

|

|

300 kg

|

|

||||

Machine Details

Applicable Products

Horizontal Sleeve Labeling Machine

Machine Advantages

Driving part:

Synchronized mechanism drive, each drive belt replacement can be completed quickly, and the traditional multi-layer link-arm type (replacement and repair takes more than six hours) compared with easy maintenance, simple maintenance, and never affect production.

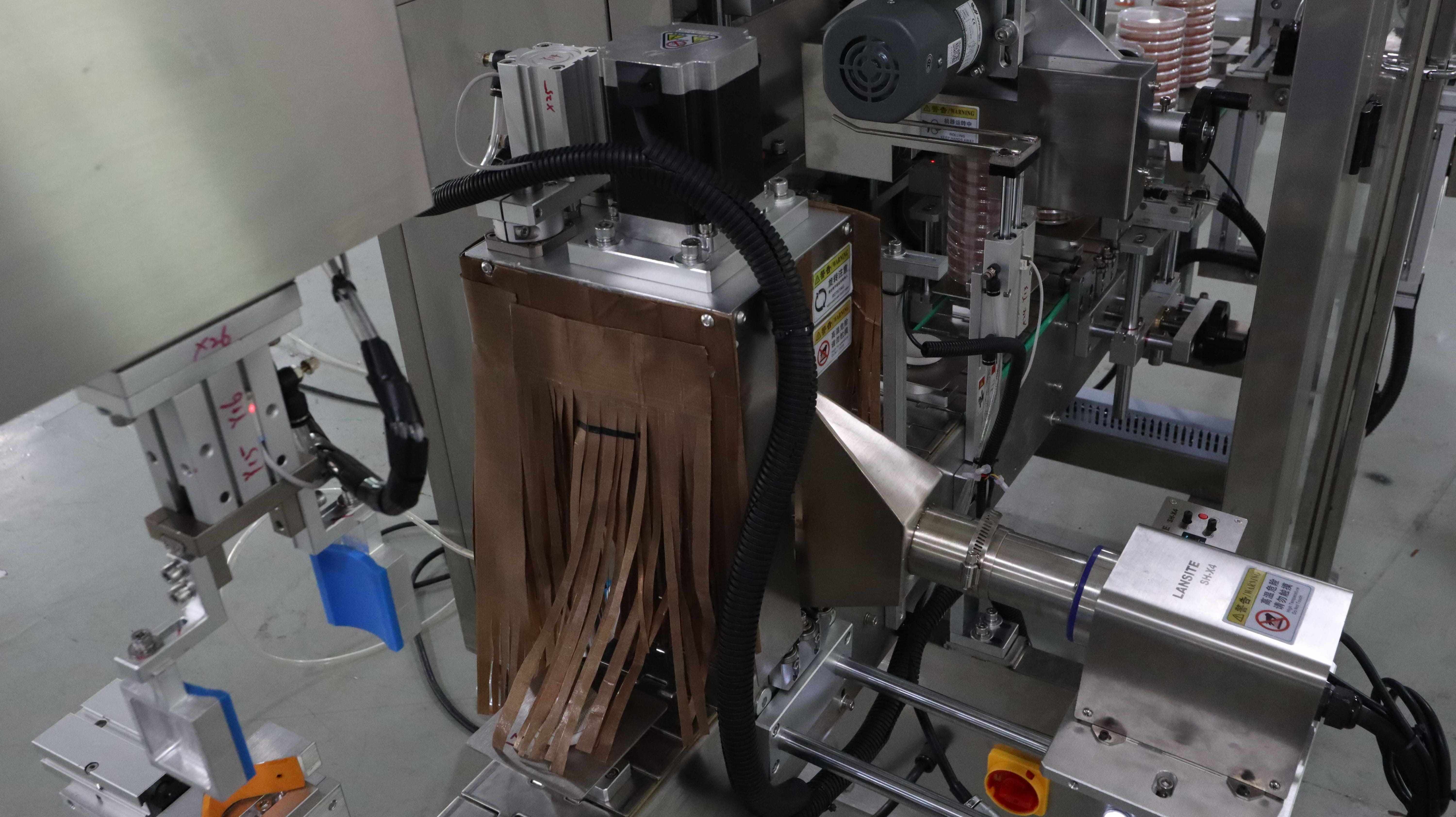

Cutter set:

New cutter design using servo motor drive, high speed, stable and accurate action, flat cut, shrinkage and beautiful, with the label synchronization positioning mechanism, cutter positioning accuracy up to 1mm. unique cutter seat design, suitable for 30mm ~ 130mm containers, cutter seat completely free of replacement, free of debugging, cutter plate origin sensor is built into the internal cutter plate, no need to read the synchronous belt when disassembling the cutter plate. There is no need to check the position of the belt when disassembling the cutter. The exclusive use of a light touch man-machine automatically searches for the original position, which is safe and convenient, and is ahead of similar products.

The new cutter design is driven by stepping motor, with high speed, stable and accurate movement, smooth cutting, beautiful shrinkage, and with the label synchronous positioning mechanism, the accuracy of cutting positioning is up to 1mm.

Feeding group:

Adopt single shrinking material tray, increase the cache material frame design, moderate height, easy to install labels; using frequency converter and photoelectric sensing with mechanical buffer device to control the roll label tension, so that the label transport is stable and smooth, no film material automatically stops and with warning lights and touch screen Chinese display. Unique high standard detection, so that the equipment in the process of labeling timely detection of labeling errors, to prevent unqualified products into the downstream process.

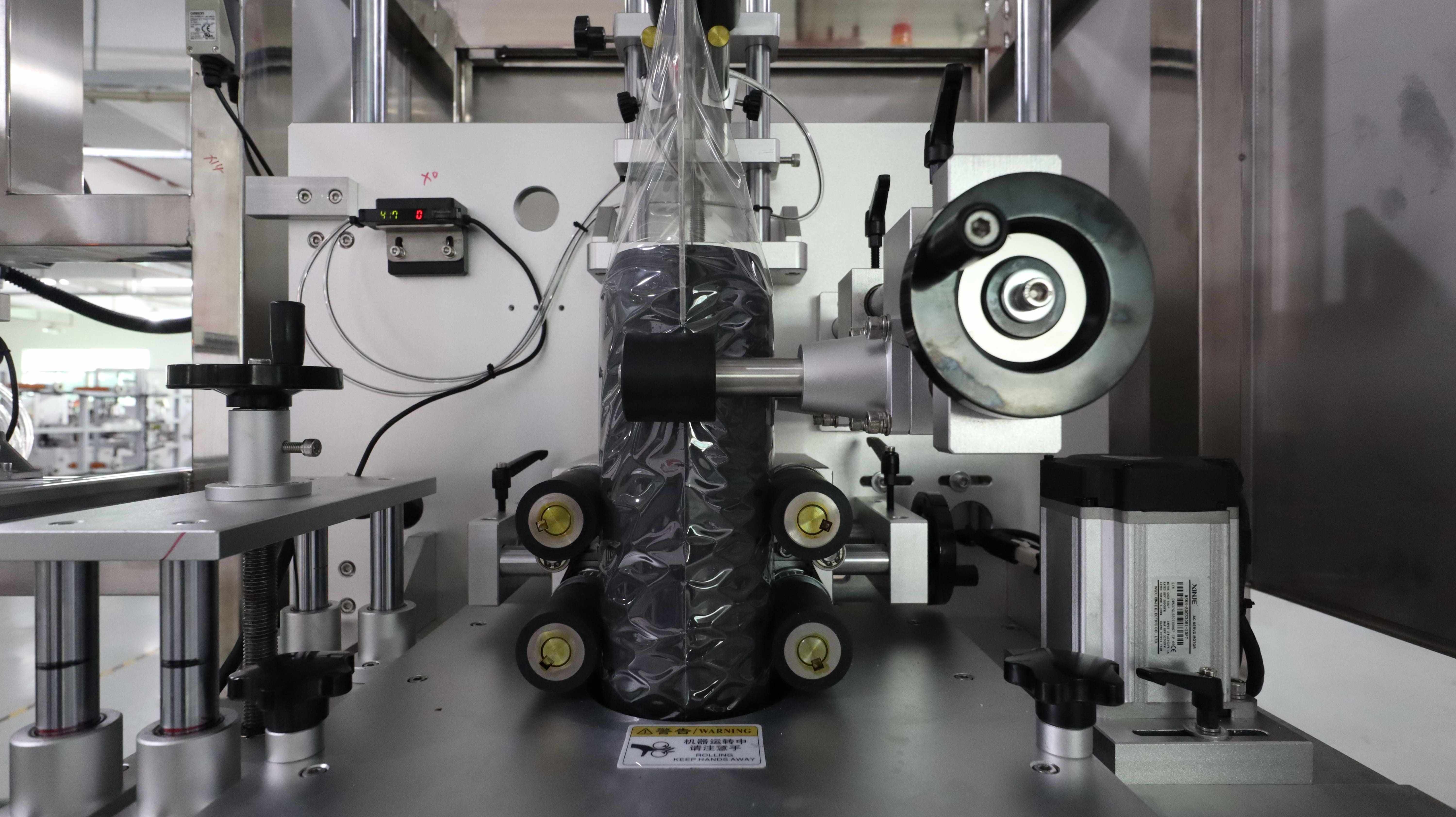

Brush down group:

Adopting a motor with double-sided arc synchronous belt to synchronize the brush down rubber wheels to ensure the stability of labeling.

With bottle group:

Adopting mechanical transmission to drive the bottle positioning belt on both sides. When changing the specification of the whole bottle group, the lifting, width and narrowing of the bottle group are synchronized with a hand wheel to achieve quick and convenient adjustment.

Machine lifting group:

Synchronized mechanism drive, each drive belt replacement can be completed quickly, and the traditional multi-layer link-arm type (replacement and repair takes more than six hours) compared with easy maintenance, simple maintenance, and never affect production.

Cutter set:

New cutter design using servo motor drive, high speed, stable and accurate action, flat cut, shrinkage and beautiful, with the label synchronization positioning mechanism, cutter positioning accuracy up to 1mm. unique cutter seat design, suitable for 30mm ~ 130mm containers, cutter seat completely free of replacement, free of debugging, cutter plate origin sensor is built into the internal cutter plate, no need to read the synchronous belt when disassembling the cutter plate. There is no need to check the position of the belt when disassembling the cutter. The exclusive use of a light touch man-machine automatically searches for the original position, which is safe and convenient, and is ahead of similar products.

The new cutter design is driven by stepping motor, with high speed, stable and accurate movement, smooth cutting, beautiful shrinkage, and with the label synchronous positioning mechanism, the accuracy of cutting positioning is up to 1mm.

Feeding group:

Adopt single shrinking material tray, increase the cache material frame design, moderate height, easy to install labels; using frequency converter and photoelectric sensing with mechanical buffer device to control the roll label tension, so that the label transport is stable and smooth, no film material automatically stops and with warning lights and touch screen Chinese display. Unique high standard detection, so that the equipment in the process of labeling timely detection of labeling errors, to prevent unqualified products into the downstream process.

Brush down group:

Adopting a motor with double-sided arc synchronous belt to synchronize the brush down rubber wheels to ensure the stability of labeling.

With bottle group:

Adopting mechanical transmission to drive the bottle positioning belt on both sides. When changing the specification of the whole bottle group, the lifting, width and narrowing of the bottle group are synchronized with a hand wheel to achieve quick and convenient adjustment.

Machine lifting group:

adopts electric lifting, which is more convenient to operate.

Fabrication Area and Assembly Area

All the accurate mechanical parts are fabricated in the Mazak CNC center. The fabrication accuracy: 0.005 mm.Over 90% of the mechanical parts are fabricated in our workshop to ensure part accuracy and machine stability.

Gosunm has been developina and producing labelina machines since 2007. With 15 vears of experience. serving more than 3,000 customers worldwide and accumulating a large number of labeling applications and experiences.

Gosunm labeling machines are very popular among customers.

Based on years of experience and the actual needs of customers, we have developed a variety of bottle labeling machines.

GST-216H

Fully Automatic

Rotary Labeling Machine

GST-413 semi-automatic round bottle labeling machine

GST-211T Desktop Rolling Round Bottle Labeling Machine

GST-212T Desktop type positioning round bottle labeling machine

GST-211 Vertical Rolling Round Bottle Labeling Machine

GST-212 Vertical positioning round bottle labeling machine

GST-219 Horizontal round bottle labeling machine

GST-250E Electric heating sleeve labeling machine

GST-250S Steam sleeve label machine

GST-250H Horizontal Labeling Machine

GST-711 Single side bottle/barrel labeling machine

GST-712 Double-sided bottle/barrel labeling machine

The above labeling machines can meet most customers' bottle/can/barrel labeling needs, and are suitable for daily chemical products, alcoholic beverages, pharmaceutical industry, e-commerce and many other industries. These standard round bottle labeling machines, which have been verified by our customers for many years in practice, have good machine stability, easy installation and simple operation.

in addition to the above standard models of round bottle labeling machines, we can also customize them based on customers requirement. These machines can be used individually or connected to production lines.

Quality Control

1. Technical dept

①Evaluate the technical parameters of the project.

②Evaluate whether the technical proposal can be fully implemented under the contract, and if so, implement the original proposal. If not, propose a new proposal and confirm with the customer.

③Perform 3D layout.

④Review the overall design layout to ensure that it is reasonable and that all parameters can be achieved. Check whether the

components of brand/materials/ power source/ gas source are in accordance with the requirements of the contract, check whether the packing size is in accordance with the transportation requirements of the customer.

⑤ Make detailed drawings and lists, and check that the material surface treatment of the drawing and the number of drawing lists are correct.

②Evaluate whether the technical proposal can be fully implemented under the contract, and if so, implement the original proposal. If not, propose a new proposal and confirm with the customer.

③Perform 3D layout.

④Review the overall design layout to ensure that it is reasonable and that all parameters can be achieved. Check whether the

components of brand/materials/ power source/ gas source are in accordance with the requirements of the contract, check whether the packing size is in accordance with the transportation requirements of the customer.

⑤ Make detailed drawings and lists, and check that the material surface treatment of the drawing and the number of drawing lists are correct.

2.Procurement dept

①Review the purchase list and drawings provided by the technical department. If some items cannot meet the lead time, report it to sales and customers to apply for a replacement. choose a supplier with excellent quality.

②Check whether the material is correct after it is in warehouse. Check the size and accuracy range.

③After checking the incoming material, inform production dept to take the material for assembling.

②Check whether the material is correct after it is in warehouse. Check the size and accuracy range.

③After checking the incoming material, inform production dept to take the material for assembling.

3. Assembly dept

①According to the technical parameters, specify all the technical indicators to be achieved.

②Receive materials according to the technical list and make sure the materials are correct.

③Install and wire the equipment according to the equipment drawings.

④Manual testing of each mechanism to see if it meets the requirements of the contract.

②Receive materials according to the technical list and make sure the materials are correct.

③Install and wire the equipment according to the equipment drawings.

④Manual testing of each mechanism to see if it meets the requirements of the contract.

4. Commissioning dept

① Check all information according to the production order (the order includes all technical parameters of the contract)

② According to the production order to adjust the equipment, test the machine with factory samples and then test the machines with customer samples.

③ To optimize the details of the equipment until the equipment can meet the specifications such as production rate, speed.

④ Aging test for the equipment

② According to the production order to adjust the equipment, test the machine with factory samples and then test the machines with customer samples.

③ To optimize the details of the equipment until the equipment can meet the specifications such as production rate, speed.

④ Aging test for the equipment

5. Inspection dept

① According to the order details, check the actual production speed and the qualified rate.

② Check the appearance and safety of the equipment, and check whether the holding degree of each mechanism meets the order.

③ Confirm the check list has been done one by one, issue the acceptance list, and inform the sales department to contact the customer for shipment after all are qualified.

② Check the appearance and safety of the equipment, and check whether the holding degree of each mechanism meets the order.

③ Confirm the check list has been done one by one, issue the acceptance list, and inform the sales department to contact the customer for shipment after all are qualified.

FAQ

1. who are we?

We are based in Guangdong, China, start from 2012,sell to Domestic Market(40.00%),Eastern Asia(30.00%),North America(10.00%),Mid

East(4.00%),South America(3.00%),Western Europe(3.00%),Eastern Europe(2.00%),Southeast Asia(2.00%),Oceania(2.00%),Northern

Europe(2.00%),Southern Europe(2.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Mask Making Machine,Labeling Machine,Filling Machine,Dimension Weight Scanner

4. why should you buy from us not from other suppliers?

rely on strong product lines and exquisite technology, exceeding customer expectations to provide a one-stop quality products and

services. Gosunm Machinery had already been exported to more than 100+ countries.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Korean

We are based in Guangdong, China, start from 2012,sell to Domestic Market(40.00%),Eastern Asia(30.00%),North America(10.00%),Mid

East(4.00%),South America(3.00%),Western Europe(3.00%),Eastern Europe(2.00%),Southeast Asia(2.00%),Oceania(2.00%),Northern

Europe(2.00%),Southern Europe(2.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Mask Making Machine,Labeling Machine,Filling Machine,Dimension Weight Scanner

4. why should you buy from us not from other suppliers?

rely on strong product lines and exquisite technology, exceeding customer expectations to provide a one-stop quality products and

services. Gosunm Machinery had already been exported to more than 100+ countries.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Korean

Hot Searches