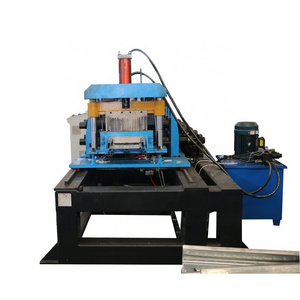

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

Eps sandwich panel machine

-

Power:

-

Hydraulic

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Panel thickness:

-

40mm-250mm

-

material of cutting blade:

-

Cr12

-

Plc:

-

DETLA

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

4-5 m/min

-

Place of Origin:

-

Tianjin, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

Eps sandwich panel machine

-

Power:

-

Hydraulic

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Panel thickness:

-

40mm-250mm

-

material of cutting blade:

-

Cr12

-

Plc:

-

DETLA

-

Certification:

-

CE/ISO9001

Welcome to YUFADA,we are your China Manufacturer High Quality Cheap Price roof roll forming machine and c&zpurlin maintain expert.

Home Products categories Company profile Contacts

Now our EPS/ROCK WOOL roll forming machine have been exported to many countries,the most important is that all you need can be customized.

Composite Decoiler—Roll Forming—laminating system (ribbon, gelatinizing, heating up, compounding, crimping, notching, edge trimmer)—cutting system—Runout Table

2) Thickness of the plate : 0.3-0.8mm

3) Core thickness: 40-250mm

4) Production capacity(according to your glue ):

4-4.5m/min (the fastest), 2-2.5m/min (the slowest)

5) Total power: about 32KW

6) Weight: 25 ton

7) PLC control system, easy to operate, high precision and work stably.

8) Dimensions of whole production line:

about Length 35m × Width 2.5m × Height2.6m

9) Voltage: 380v 50hz 3-phase