- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUKUO

-

Model Number:

-

NGPF-96

-

Surface Treatment:

-

High Quality Gel Coated

-

Color:

-

White/Blue/Customized

-

Material:

-

FRP sheet and core material

-

Cover Materials:

-

Fiberglass Reinforced Polyester (FRP)

-

Core material:

-

plywood panel

-

Applications:

-

Dry freight truck bodies, Truck door panels, Caravans

-

FRP Thickness:

-

1mm-3mm

-

Core Thickness:

-

3mm-20mm

-

Max. Width:

-

1220mm

-

Max. Length:

-

2440mm

-

Feature:

-

Corrosion Resistance

Quick Details

-

Application:

-

Construction

-

Technique:

-

Continuous Panel Molding

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YUKUO

-

Model Number:

-

NGPF-96

-

Surface Treatment:

-

High Quality Gel Coated

-

Color:

-

White/Blue/Customized

-

Material:

-

FRP sheet and core material

-

Cover Materials:

-

Fiberglass Reinforced Polyester (FRP)

-

Core material:

-

plywood panel

-

Applications:

-

Dry freight truck bodies, Truck door panels, Caravans

-

FRP Thickness:

-

1mm-3mm

-

Core Thickness:

-

3mm-20mm

-

Max. Width:

-

1220mm

-

Max. Length:

-

2440mm

-

Feature:

-

Corrosion Resistance

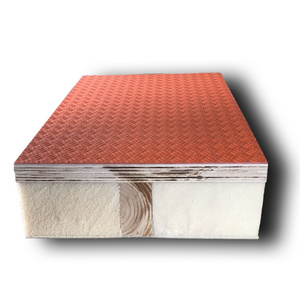

Melamine Plywood Sandwich Heat Insulation Gelcoated Frp Panel For Camper Caravan,plywood sandwich panel

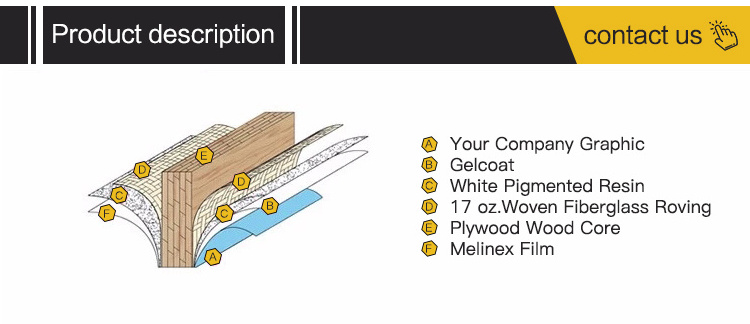

Product Description

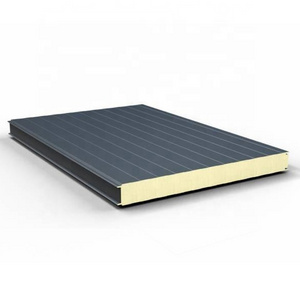

The FRP fiberglass sandwich panel is a new kind of high-quality environmental-friendly product, which is made of heat-cured gel coat, synthetic resin and fiberglass. And it's widely used in high-grade automobiles, refrigerator truck compartments and purification, medical treatment, food hygiene,food processing facilities, restaurants, commercial buildings and wash facilities and other projects.

Specification

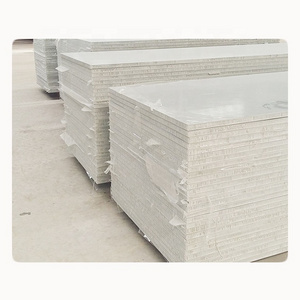

The FRP plywood sandwich is made of marine plywood with 2 layers fiberglass reinforced plastic surface sheets on both sides.

Specification:

1. FRP sheet is normally 2mm thick, can be customized as you required.

2. Surface gel coat can be chosen.

3. The FRP sheet and the core plywood are bonded together by vacuum bagging method.

Specification:

1. FRP sheet is normally 2mm thick, can be customized as you required.

2. Surface gel coat can be chosen.

3. The FRP sheet and the core plywood are bonded together by vacuum bagging method.

|

Model Number

|

NGPF-96

|

|

Application

|

Dry freight truck bodies, Truck door panels, Caravans

|

|

Surface Treatment

|

High Glossy/Woven Roving/Chopped Strand Mat/Matte/Embossed, etc

|

|

Technique

|

FRP Continuous Production

|

|

Processing Service

|

Bending, Decoiling, Moulding, Welding, Punching, Cutting

|

|

Color

|

White or customized

|

|

Material

|

FRP sheet and core material

|

|

Cover Materials

|

Fiberglass Reinforced Polyester (FRP)

|

|

Core material

|

Plywood panel

|

|

FRP Thickness

|

1mm-3mm

|

|

FRP Thickness

|

3mm-20mm

|

|

Max. Width

|

1220mm

|

|

Max. Length

|

2440mm

|

|

Panel Material

|

Pebbled Texture Panel/Smooth Panel/FRP Leaf Texture Panel

|

The above mentioned panels can be combined with the froth, gypsum, polywood, aluminium, PP, XPS, honeycomb. The sandwich panel is a more strengthen, better rigidity panel. The sandwich panels will be easier to install, the installation efficiency will be improved greatly, furthermore, the requirement of wall coarseness will be reduced.

Product Details

Features

of FRP

fiberglass reinforced plastic plywood sandwich panel

1.

FRP plywood sandwich panel, which is made of high quality filberglass panel and environmental plywood made of special polyester or polyurethane glue. It has the features of beauty, high strength and impact resistance.

2.

The surface of the FRP panel is smooth ane flat. With the exception of the usual white. it can be customizing according to the customer's requirements.

3.

The compressive strength can reach 70Mpa.

4.

Waterproof: the wood plywood core is made of environmentally waterproof glue, and there is no obvious cracking for 7 hours.

Application

Application of

FRP fiberglass reinforced plastic plywood sandwich panel

1)Temporary offices,dormitories,warehouse and workshop in construction sites and in municipal works and residential resettlements 2) Temporary commercial housings in the cities,such as exhibition halls,shopping centers,offices and other housings for exhibition and sports 3) Holiday inns or container house,leisure villas and holiday homes in tourist spots. 4) Temporary houses used in large-scale fieldwork,such as exploiting energy sources and making tunnels,warehouse 5) Temporary houses in military field and temporary housings in earthquake,fire, hurricane and flood disaster-affected areas 6) large area suspended ceiling,separation of steel structure workshop,suspended ceiling,wall body and air purification room. Dry freight truck bodies, t ruck door panels, caravans.

1)Temporary offices,dormitories,warehouse and workshop in construction sites and in municipal works and residential resettlements 2) Temporary commercial housings in the cities,such as exhibition halls,shopping centers,offices and other housings for exhibition and sports 3) Holiday inns or container house,leisure villas and holiday homes in tourist spots. 4) Temporary houses used in large-scale fieldwork,such as exploiting energy sources and making tunnels,warehouse 5) Temporary houses in military field and temporary housings in earthquake,fire, hurricane and flood disaster-affected areas 6) large area suspended ceiling,separation of steel structure workshop,suspended ceiling,wall body and air purification room. Dry freight truck bodies, t ruck door panels, caravans.

Packing & Delivery

Packing Details:

FRP fiberglass reinforced plastic plywood sandwich panel

are well packaged with all the necessary materials.

Bulk, Carton box, wooden pallet, steel pallet or as per customers' requirements.

Delivery Details:

5-30days

|

Package

|

1. Plywood Pallet

2. Plywood case

3. Customized

|

|

|

Delivery

|

1. Samples: 2-3 days if we have in stock;

2. Mass production: 15 working days

3. Delivery terms: EXW, FOB, CIF, DDP all can be accepted

|

|

|

Corrosion Resistance PU XPS FRP Fiberglass Sandwich Panel

|

|

|

Hot Searches