- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Place of Origin:

-

Istanbul, Turkey

-

Brand Name:

-

BAUMERK

-

Model Number:

-

PUK 401

-

Type:

-

Other Waterproofing Materials

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Place of Origin:

-

Istanbul, Turkey

-

Brand Name:

-

BAUMERK

-

Model Number:

-

PUK 401

-

Type:

-

Other Waterproofing Materials

Description

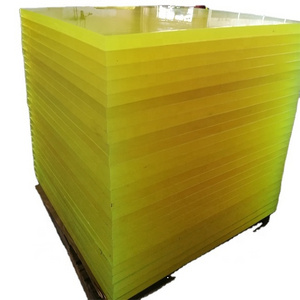

PUK 401 is a polyurethane-coal tar based, two component, cold applied, self-leveling joint sealant with excellent adhesion performance, abrasion, UV light, mechanical, chemical and jet fuel resistance.

Fields of Application

PUK 401 is produced especially for airports, runways, park areas, hangars, loading areas.

It is suitable for road and concrete areas such as in tunnel, bridge, canals, petrol stations, stadiums, sidewalks, refinery and petrochemicals, harbor and other industrial facilities.

It is suitable for all kinds of horizontal outdoor joints.

Features and Benefits

Provides permanent high elasticity at temperatures between -35°C to +85°C.

Cold applicable.

Suitable for joints of expressways and roads with heavy traffic conditions.

Resistant to abrasion.

Has excellent adhesion on different surfaces such as concrete, wood, metal etc.

Resistant to UV.

Resistant to jet fuels, oils, acids and bases.

Technical Data

|

Content Density Solid Content Shore A Hardness Adhesion/Cohesion Properties Hydrolysis Resistance Burning Resistance Mass and volume change after immersed test fuel Adhesion/cohesion properties after immersed chemicals Volume Loss Sagging Resistance Tensile Modulus Elasticity recovery Service Temperature Application Temperature Pot Life Drying Time Touch dry Mechanical strength HS Code |

Coal Tar – Polyurethane Based 1,25 g/cm 3 96% 25±5 No Adhesion/Cohesion at 0,31 MPa (TS EN ISO 9047) 40% (TS EN 14187-5) Proper (TS EN 14187-7) Mass 8% / Volume 10% (TS EN 14187-4)

No adhesion/cohesion (Class D) (TS EN 14187-6)

2,7% (TS EN ISO 10563) No sagging (TS 1092) 0,16 MPa (at 23°C) / 0,22 MPa (at -20°C) 80% (TS EN ISO 7389) -35°C to +86°C +5°C to +35°C 30-40 minutes

48 hours 7 days 3214.10.10.00.12 |

Application Procedure

Preparation of Substrate

The surface must be dry and clean before application. All joints before filling shall be carefully cleaned by metal brushing or sanding. The dust should be removed by pressured air. PUK 401 causes foaming when applied on moist surfaces. Therefore the joints must be dry and the sealant must not contact water until chemical curing occurs.

Application Method

Component A and B is mixed under low speed mixer until homogenous mixture obtained. Mixture must be used within 30-45 minutes. Otherwise gelling occurs and it cannot be recovered.

Consumption

1,25 kg/lt

Packaging

A component + B component = 5 kg set