- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SDQC2717

-

Thickness:

-

10-300mm

-

Size:

-

cut to size as your need

-

Standard color::

-

natural/blue/green/black/yellow/red/orange(other color is available )

-

Inspection::

-

GB/T 19001-2008 ; ISO 9001:2008

-

Molecular weight::

-

3million -9million

-

Breaking elongation::

-

>300%

-

Impact strength::

-

131Mj/mm2

-

Density::

-

0.93-0.97

-

Thickness tolerance::

-

+2 -1 (some made according to your requirements)

-

Abrasion::

-

80, steel = 100

-

Friction Coefficient::

-

0.12-0.15

-

shape::

-

sheet/board/pad/panel/roll

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QiCheng

-

Model Number:

-

SDQC2717

-

Thickness:

-

10-300mm

-

Size:

-

cut to size as your need

-

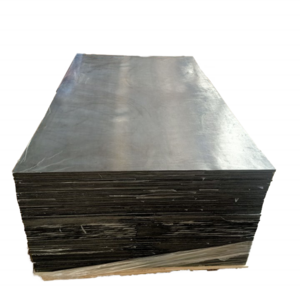

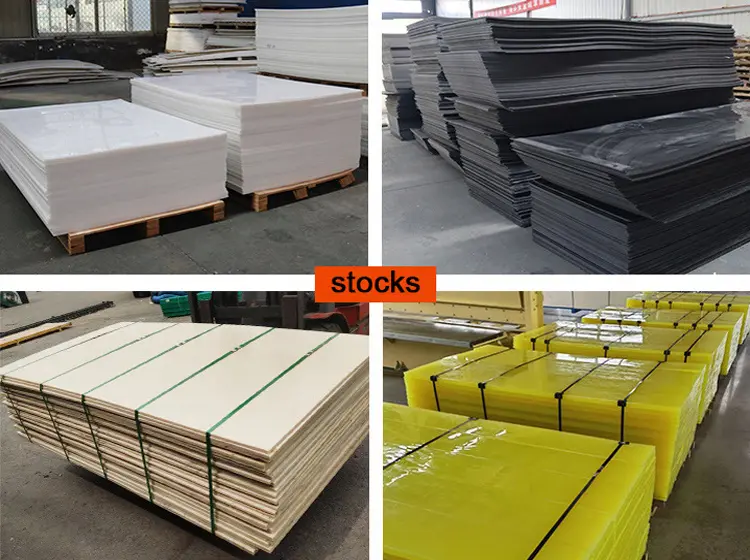

Standard color::

-

natural/blue/green/black/yellow/red/orange(other color is available )

-

Inspection::

-

GB/T 19001-2008 ; ISO 9001:2008

-

Molecular weight::

-

3million -9million

-

Breaking elongation::

-

>300%

-

Impact strength::

-

131Mj/mm2

-

Density::

-

0.93-0.97

-

Thickness tolerance::

-

+2 -1 (some made according to your requirements)

-

Abrasion::

-

80, steel = 100

-

Friction Coefficient::

-

0.12-0.15

-

shape::

-

sheet/board/pad/panel/roll

Products Description

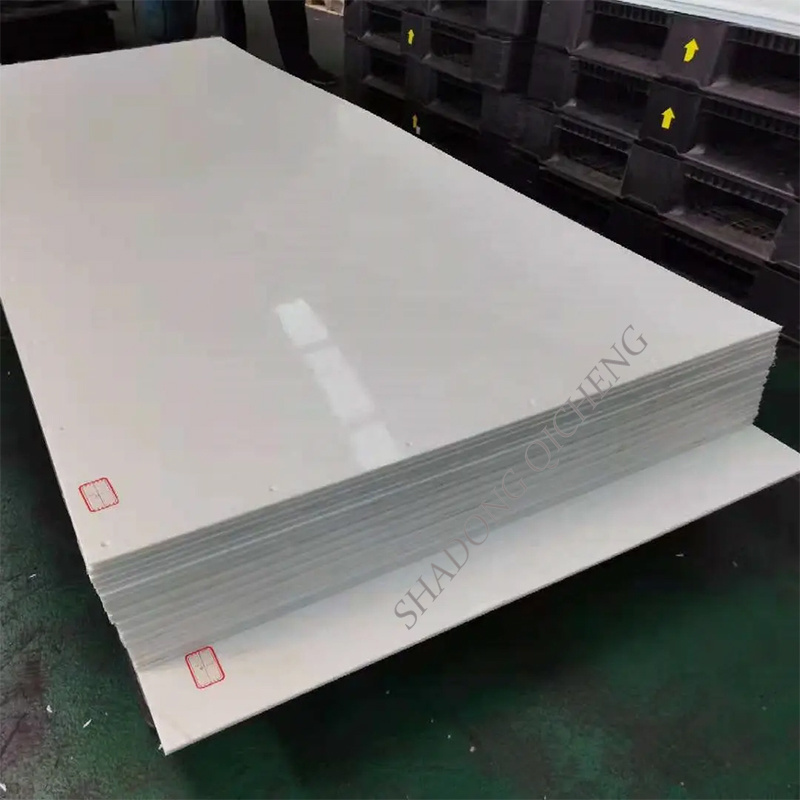

(HDPE/UHMW-PE) UHMWPE SHEET

: We can manufacture different UHMWPE Sheet according to different requirements with different application .Like anti-UV, fire-resistant,anti-static and with other characters. Best quality with good surface and color make our UHMWPE sheet more and more popular all over the world .

processing way: Compression Molding or Extrusion molding according to different thickness and load capacity.

Features:

1.Best shock resistance even in low temperature

2.Low frictional factor, and well sliding bearing material

3.Lubricity(no caking, in adhesion)

4.Best chemical corrosion resistance and stress craze resistance

5.Excellent machinery process ability

6.Lowest water absorption

6.Lowest water absorption

7.Paragon electric insulativity and anti-static behavior

8.Nice high energy radioactive resistance

9.Abrasive resistance which always have in thermoelectricity polymer

9.Abrasive resistance which always have in thermoelectricity polymer

10.Density is lower than other thermoplastic Two different

processing way: Compression Molding or Extrusion molding according to different thickness and load capacity.

Product Paramenters

|

Item

|

Units

|

ASTM test

|

HDPE

|

UHMW-PE

|

|

Tensile strength

|

PSI

|

D-638

|

4000

|

3100

|

|

Flexural modulus

|

PSI

|

D-790

|

200000

|

110000

|

|

Notched impact

|

Ft-lbs/in of notch

|

D-256

|

1.3

|

18

|

|

Heat deflection temperature at 66psi

|

℉

|

D-648

|

172

|

-

|

|

Maximum continuous service temperature in air

|

℉

|

|

-

|

180

|

|

Water absorotion

|

%

|

D-570

|

0.10

|

slight

|

|

Coeff icient of liner thermal expansion

|

In/in℉10-5

|

D-696

|

7

|

11.1

|

|

Property

|

Standard

|

Unit

|

UHMWPE

|

|

Physical Properties

|

|

|

|

|

Density

|

GB1033-86

|

g/cm3

|

0.93

|

|

Water Absorption

|

GB1034-86

|

%

|

< 0.01

|

|

Max Working Temperature

|

-

|

°C

|

90

|

|

Minimum Working Temperature

|

-

|

°C

|

-269

|

|

Mechanical Properties

|

-

|

-

|

-

|

|

Tensile Strength

|

GB1040-79

|

MPa

|

21

|

|

Ultimate Tensile Strength

|

GB1040-79

|

MPa

|

38

|

|

Elongation

|

GB1040-79

|

%

|

12

|

|

Break Elongation

|

GB1040-79

|

%

|

340

|

|

E-Modulus

|

GB1040-79

|

MPa

|

820

|

|

Notched Impact Strength

|

GB1843-80

|

KJ/m2

|

ok

|

|

Bending Strength

|

GB9341-88

|

MPa

|

26

|

|

Bending E-Modulus

|

GB9341--88

|

MPa

|

760

|

|

Compression Strength (deformation 10%)

|

GB1041-79

|

MPa

|

27

|

|

Compression E-Modulus

|

GB1041-79

|

MPa

|

550

|

|

Shear Strength

|

GB1041-79

|

MPa

|

33

|

|

Hadrness

|

GB2411-80

|

Shore D

|

65

|

|

Static Coefficient of Friction

|

GB10006-88

|

-

|

0.07-0.15

|

|

Dynamic Coefficient Friction

|

GB10006-88

|

-

|

0.07-0.11

|

|

Thermal Properties

|

-

|

-

|

-

|

|

Coefficient of Linear Expansion

|

GB1036-89

|

°C-1

|

1.5×10-4

|

|

Coefficient of Heat Conductivity ( 23 °C )

|

GB3399-82

|

Cal/cm sec °C

|

8.5×10-4

|

|

Special Heat ( 23 °C)

|

GB3399-82

|

Cal/g°C

|

0.44

|

|

Electrical Properties

|

-

|

-

|

-

|

|

Volume Resistivity

|

GB1410-78

|

Ohm cm

|

>1015

|

|

Surface Resistivity

|

GB1410-78

|

Ohm

|

>1015

|

|

Dielectric Constant ( 1MHZ )

|

GB1409-78

|

-

|

3

|

|

Dielectric Strength

|

GB1408-78

|

Kv/mm

|

70

|

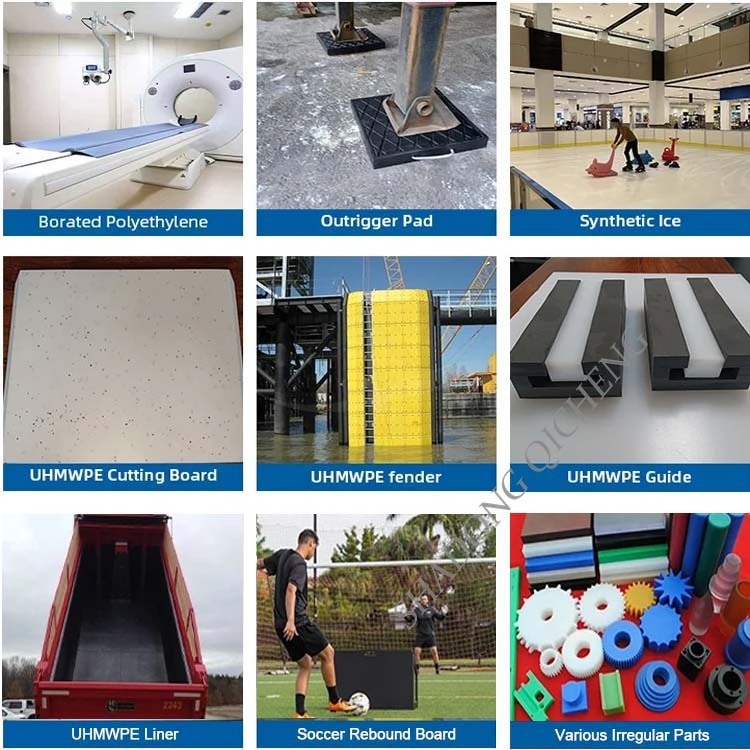

Application

Specification: Length, width, and thickness according to customer's requirement.

Characteristics: Excellent thermoforming performance, high impact strength

Application: Automobile, bus interior top, instrument desk, seat & backup plate, service door board, window frame, boxes & cases, medical equipment, motorbike shell, refrigerator inner liners and door liners, wall cabinets, drinking fountains interior, outermost shell of equipments, etc.

Production Process

Hot Searches