- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Fiberglass Composites

-

Place of Origin:

-

China

-

Product name:

-

Spa mold

-

Color:

-

grey

-

Shape:

-

rectangle

-

Seatings:

-

1 seat

-

Size:

-

1890*890*830mm

-

Loading Port:

-

Shenzhen / Guangzhou

-

Delivery Time:

-

3-6 weeks

-

Shipping way:

-

by sea

-

Quality:

-

Good, brand-new

Quick Details

-

Project Solution Capability:

-

Others

-

Application:

-

Bathroom

-

Design Style:

-

Modern

-

Material:

-

Fiberglass Composites

-

Place of Origin:

-

China

-

Product name:

-

Spa mold

-

Color:

-

grey

-

Shape:

-

rectangle

-

Seatings:

-

1 seat

-

Size:

-

1890*890*830mm

-

Loading Port:

-

Shenzhen / Guangzhou

-

Delivery Time:

-

3-6 weeks

-

Shipping way:

-

by sea

-

Quality:

-

Good, brand-new

Product Description

Spa mould is the source of the product, and its quality will directly determine the quality of the spa shell.

IT IS ALL CUSTOM BUILT BY HAND!

It takes us weeks to do the polishing & sanding by hand, in order to have the perfect smoothness, and the graceful curved surfaces.

hand-crafted by our experienced designers and veteran workers, every ergonomic seating and curved details are carefully thought out and hand-made to provide the ultimate in comfort, safety and aesthetics;

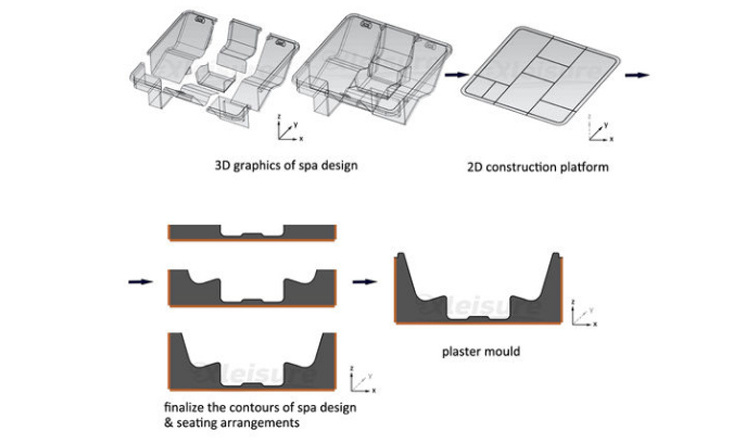

3D MODELING FOR ODM SPA MOULD

- using advanced computer assisted design (CAD) and 3D modeling, we created the formfitting seats that perfectly accommodate the body;

CRAFTED BY HAND, FROM SCRATCH, MOLDED TO PERFECTION

- every hot tub spa mould is sculpted by hand, to achieve the smoothness and feel of every contour of the spa that no machine can deliver. This sculpting process can take months to perfect.

gel-coast on mould surface

- highly resistant to high temperature, and it features smooth surface finish and texture, and exceptional durability;

great mechanical properties, great gloss, and heat resistance and flexibility to the final mould;

the shells thermoformed from our mould come with superb smooth surface finish.

high quality fiberglass mat

- soft and more penetrative, more strength

bonding resin

- professional specialty resin features perfect bonding capability, high-temperature resistant

used for 3000 times thermo-forming

under proper care and maintenance

|

dimension

|

1890*890*830mm

|

|

corner radius

|

no corners, rectangle shape

|

|

seating arrangements

|

1 spacious king seats with wrist hydo-massage

|

|

filter housing

|

single-port skimmer with front access

|

|

water features

|

custom-made

|

|

other features

|

compact design, hand grip, foot massage

|

|

vacuum plumbing diameter

|

2 inch / 60mm

|

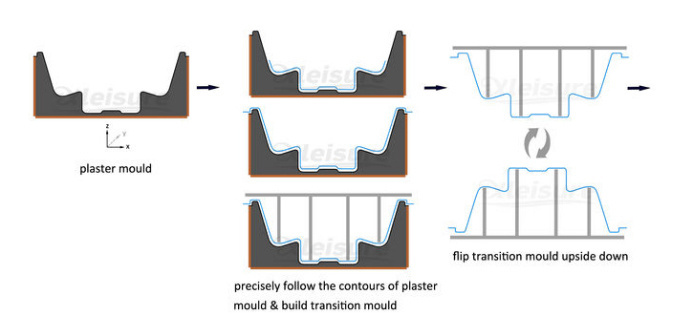

Construction Process: ( plaster mould - transition mould - final mould)

1. plaster mould

- build major curves, seating shape, the contours of spa desgin;

- build major curves, seating shape, the contours of spa desgin;

2. transiton mould

- add small stick-out structure for jets, pillows, topside valves, bottom texture etc.

3. final mould

- add steel sub-frame, wheels and thermoforming plumbing, then polish & sand the surface

Related Products

Packing&Shipping

Company Introduction

FAQ

Hot Searches