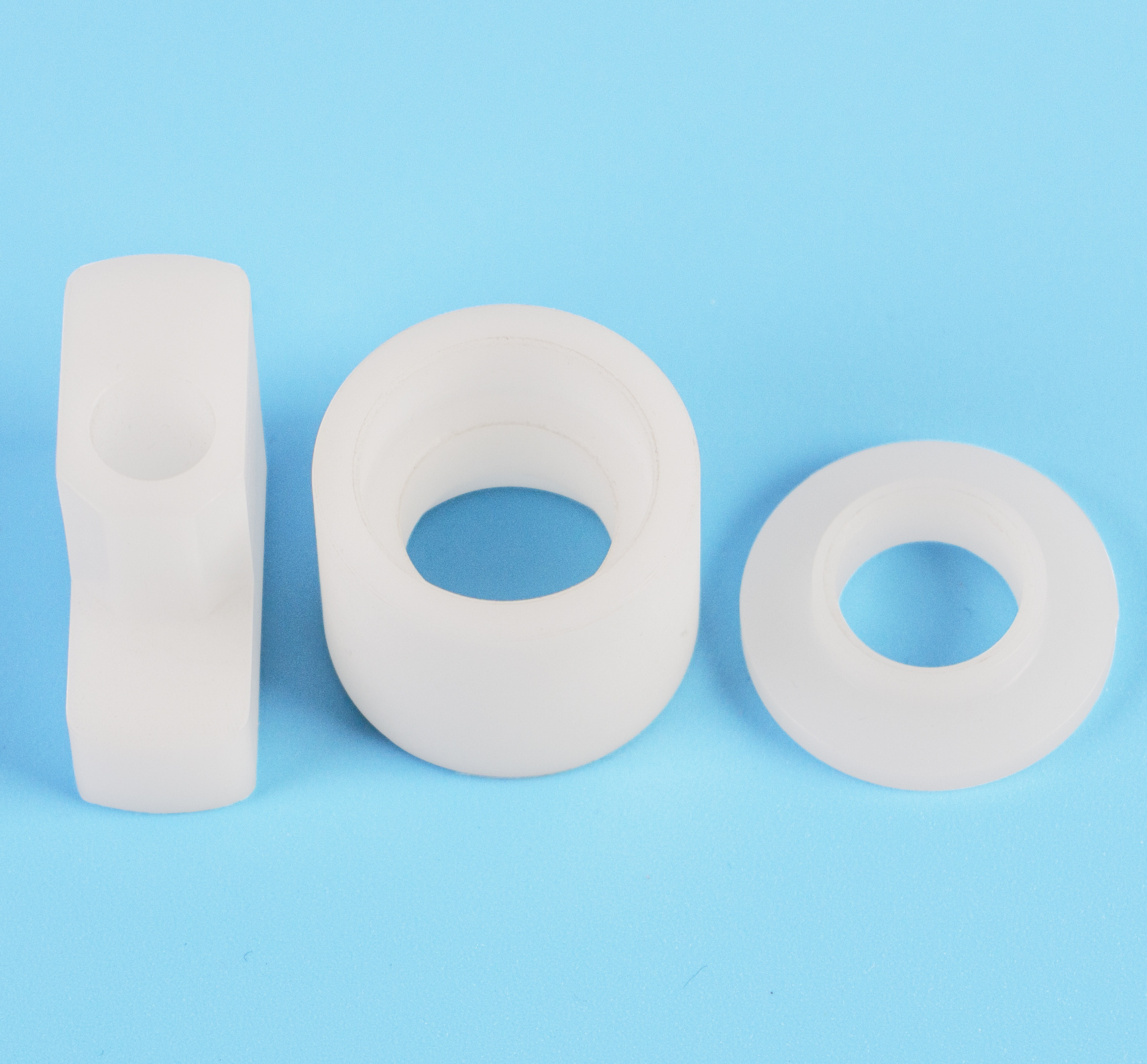

ETFE has better creep resistance and compressive strength than PTFE, and its tensile strength can reach 50MPa.

It is close to 2 times of PTFE, and the elongation can reach 100~300%.

|

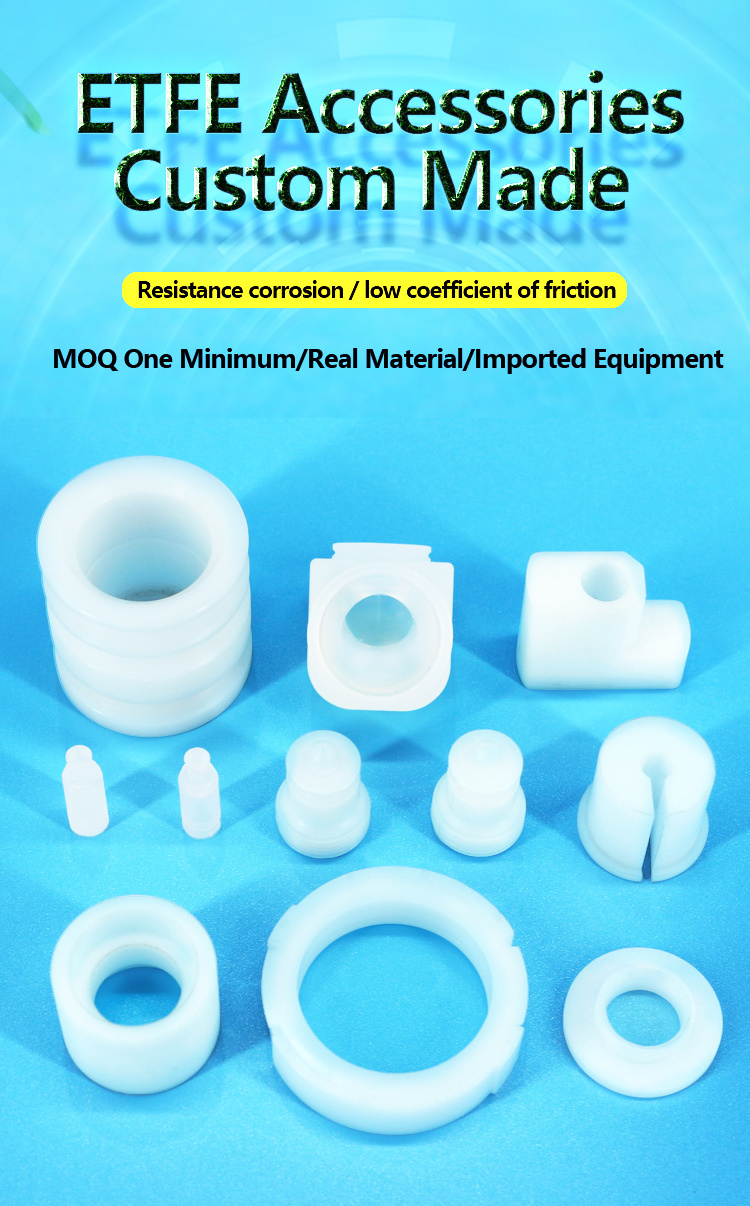

Custom CNC Machining Parts Services

|

|

|

|

Quotation

|

According to your drawing(size,material,thickness,processing content,and required technology,etc)

|

|

|

Material

|

Metal: Stainless steel, aluminum alloy, brass, steel;Plastic:ETFE,PTFE,PFA, Nylon, PC, Pvc,etc

|

|

|

Process

|

CNC Milling, CNC Turning, Auto lathe,Drilling Laser Cutting,etc

|

|

|

Surface

|

Treatment Powder coating, anodizing, polishing, electroplating,etc

|

|

|

Processing equipment

|

CNC lathe, CNC milling machine, drilling machine; Core machine, Cutting machine

|

|

|

Accept drawings

|

CAD (DXE.DWG), PDF, Pro/Engineer

|

|

|

Tolerance

|

+/-0.02mm

|

|

|

Quality Assurance

|

ISO9001:2015

|

|

|

Delivery time

|

1-2 weeks for samples, 3-4 weeks for mass production

|

|