- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Model Number:

-

20M-80M

-

Application:

-

Cost-effective Steel Structure

-

Product name:

-

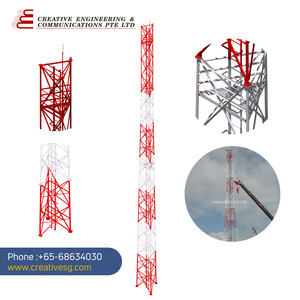

tower

Product Overview

Essential details

Model Number:

30m-80m

Type:

Telecommunication Tower

Place of Origin: ShanDong, China Brand Name: jiuyuan

Standard: ANSI/TIA-222-G-2005 Material: Angle Steel Q235B Q345B Q420

Certification : ISO9001:2008 SGS COC Galvanization Standard: ASTM A123/ ISO 1461

Nuts & Bolts: Grade 8.8/6.8/4.8 Name: Telecom Tower

Structure: Four Support Legs Lifetime: More than 20 Years

Wind Speed: 30M/S Welding: AWS D 1.1

Place of Origin: ShanDong, China Brand Name: jiuyuan

Standard: ANSI/TIA-222-G-2005 Material: Angle Steel Q235B Q345B Q420

Certification : ISO9001:2008 SGS COC Galvanization Standard: ASTM A123/ ISO 1461

Nuts & Bolts: Grade 8.8/6.8/4.8 Name: Telecom Tower

Structure: Four Support Legs Lifetime: More than 20 Years

Wind Speed: 30M/S Welding: AWS D 1.1

Products Description

|

Design

|

|

|

||

|

1. Design Code

|

TIA/EIA-222-G/F

|

|

||

|

Structure Steel

|

|

|

||

|

|

Mild Steel

|

High Tensile Steel

|

||

|

|

GB/T 700:Q235B, Q235C,Q235D

|

GB/T1591:Q345B, Q345C,Q3455D

|

||

|

|

ASTM A36

|

ASTM A572 Gr50

|

||

|

|

EN10025: S235JR, S235J0,S235J2

|

EN10025: S355JR,S355J0,S355J2

|

||

|

3. Design Wind Speed

|

Up to 250 km/h

|

|

||

|

4. Allowable deflection

|

0.5 ~1.0 degree @ operational speed

|

|

||

|

5. Tension strength (Mpa)

|

360~510

|

470~630

|

||

|

6. Yield strength (t≤16mm) (Mpa)

|

355

|

235

|

||

|

7. Elongation (%)

|

20

|

24

|

||

|

|

27(20°C)---Q235B(S235JR)

|

27(20°C)---Q345B(S355JR)

|

||

|

|

27(0°C)---Q235C(S235J0)

|

27(0°C)---Q345C(S355J0)

|

||

|

|

27(-20°C)---Q235D(S235J2)

|

27(-20°C)---Q345D(S355J2)

|

||

|

Bolts & Nuts

|

|

|

||

|

9. Grade

|

Grade 4.8, 6.8, 8.8

|

|

||

|

10. Standards for mechanical properties

|

|

|

||

|

10.1 Bolts

|

ISO 898-1

|

|

||

|

10.2 Nuts

|

ISO 898-2

|

|

||

|

10.3 Washers

|

ISO 6507-1

|

|

||

|

11. Standards for Dimensions

|

|

|

||

|

11.1 Bolts

|

DIN7990, DIN931, DIN933

|

|

||

|

11.2 Nuts

|

ISO4032, ISO4034

|

|

||

|

11.3 Washers

|

DIN7989, DIN127B, ISO7091

|

|

||

|

Welding

|

|

|

||

|

12. Method

|

CO2 Shielded Arc Welding & Submerged Arc Welding(SAW)

|

|

||

|

13. Standard

|

AWS D1.1

|

|

||

|

Marking

|

|

|

||

|

14. Method of marking of the members

|

Hydraulic Press Stamping

|

|

||

|

Galvanizing

|

|

|

||

|

15. Galvanization standard of steel sections

|

ISO 1461 or ASTM A123

|

|

||

|

16. Galvanization standard of bolts and nuts

|

ISO 1461 or ASTM A153

|

|

||

|

17. Factory test

|

Tensile test,Elements analysis, Sharpy test(impact test), Cold Bending,

Preece test,Hammer test |

|

||

Production Flow

Hot Searches