- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

aluminum industrial Product

-

Product name:

-

metal extrusion machine

-

Usage:

-

Kitchen Furniture Cabinet

-

Application:

-

Industrial Profile

-

Keyword:

-

copper extrusion press

-

Type:

-

Metal Processing Machine

-

Certification:

-

CE ISO

-

Name:

-

machining equipment

-

Feature:

-

whole production line

-

Advantage:

-

High Effciency

-

Machine name:

-

extrusion press

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jiuying

-

Weight (KG):

-

25000

-

Marketing Type:

-

aluminum industrial Product

-

Product name:

-

metal extrusion machine

-

Usage:

-

Kitchen Furniture Cabinet

-

Application:

-

Industrial Profile

-

Keyword:

-

copper extrusion press

-

Type:

-

Metal Processing Machine

-

Certification:

-

CE ISO

-

Name:

-

machining equipment

-

Feature:

-

whole production line

-

Advantage:

-

High Effciency

-

Machine name:

-

extrusion press

Contacts: Ruby Xue

Tel: +86-411-82766928

Email: rubyxue001@gmail.com

Mob/Wechat/Whatsapp: +86 138 4093 6601

Products Description

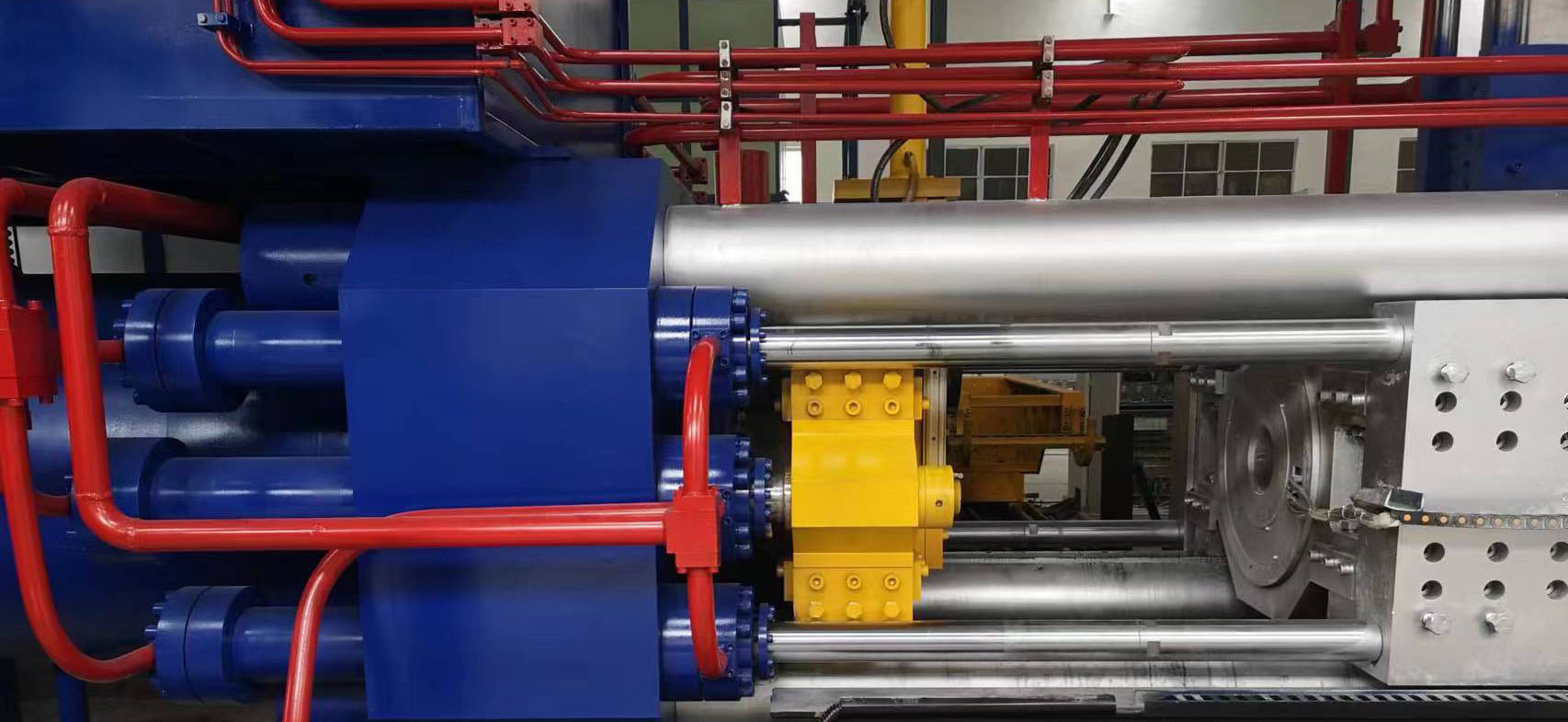

Aluminum/Copper Extrusion Press

At present, aluminum and copper profile extrusion machines have been widely used in construction, electronics, automobiles, aerospace, machine manufacturing, and other fields.

In actual production, the application rate of copper-aluminum profile extrusion machines is constantly increasing, which can meet the needs of various industries..

Features of Aluminum Extrusion Press

1. Structure

The machine has a four-column horizontal structure with a top-mounted oil tank. Its structure is compact and easy to assemble or disassemble.

2. Extrusion Process

There are two extrusion processes: following needles and fixed needles. Our machine can meet the extrusion requirements of different pipe diameters.

3. Electronic Component

We use PLC control and can do man-machine interface real-time monitoring.

4. Hydraulic System

Hydraulic system adopts large flow plug valve, stable performance, large flow, and low-temperature rise.

5. Locate Mode

The movable beam adopts four points positioning, and the center can be adjusted. It is convenient, safe, and rapid.

The machine has a four-column horizontal structure with a top-mounted oil tank. Its structure is compact and easy to assemble or disassemble.

2. Extrusion Process

There are two extrusion processes: following needles and fixed needles. Our machine can meet the extrusion requirements of different pipe diameters.

3. Electronic Component

We use PLC control and can do man-machine interface real-time monitoring.

4. Hydraulic System

Hydraulic system adopts large flow plug valve, stable performance, large flow, and low-temperature rise.

5. Locate Mode

The movable beam adopts four points positioning, and the center can be adjusted. It is convenient, safe, and rapid.

Range of Work

At present, copper and aluminum profile extrusion machines have been widely used in construction, electronics, automobiles, aerospace, machine manufacturing, and other fields.

In actual production, the application rate of copper-aluminum profile extrusion machines is constantly increasing, which can meet the needs of various industries.

Product Paramenters

|

TECHNICAL PARAMETERS FOR ALUMINUM EXTRUSION PRESS

|

|

|

|

|

|

|||||

|

Model

|

Extruding Speed

(mm/s)

|

Rated Extrusion Force

|

|

Fixed Work Stress

(MPa)

|

Main Motor Power

(KW)

|

|||||

|

XJ-630

|

40

|

6300KN

|

700UST

|

21

|

75×3

|

|||||

|

XJ-800

|

50

|

8000KN

|

880UST

|

21

|

132×3

|

|||||

|

XJ-1000

|

40

|

10000KN

|

1100UST

|

21

|

132×3

|

|||||

|

XJ-1250

|

50

|

12500KN

|

1350UST

|

21

|

132×4

|

|||||

|

XJ-1630

|

40

|

16300KN

|

1800UST

|

21

|

132×5

|

|||||

|

XJ-1800

|

40

|

18000KN

|

2000UST

|

21

|

132×6

|

|||||

|

XJ-2200

|

40

|

22000KN

|

2420UST

|

21

|

132×7

|

|||||

|

XJ-2500

|

40

|

25000KN

|

2750UST

|

21

|

132×8

|

|||||

Mechanical Part

The mechanical part is composed of base, prestressed frame type tension column, front beam, movable beam, X-shaped oriented extrusion cylinder seat, extrusion shaft, ingot feeding mechanism, residual material separation shear, sliding die base, etc.

Hydraulic Part

The hydraulic system is mainly composed of master cylinder, side cylinder, locking cylinder, perforated cylinder, large-capacity axial piston variable pump, electro-hydraulic ratio servo valve (or electro-hydraulic proportional regulating valve), position sensor, oil pipe, oil tank and various hydraulic pressure switch composition.

Electrical Part

The electrical part is mainly composed of power supply cabinet, operation console, PLC programmable controller, upper industrial control machine and display screen.

Recommend Products

Hot Searches