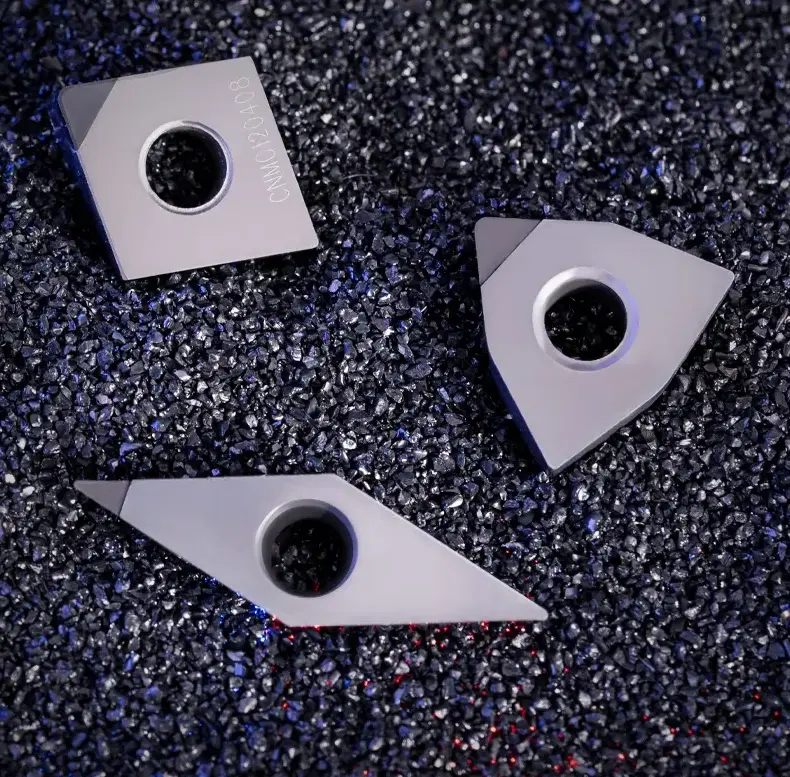

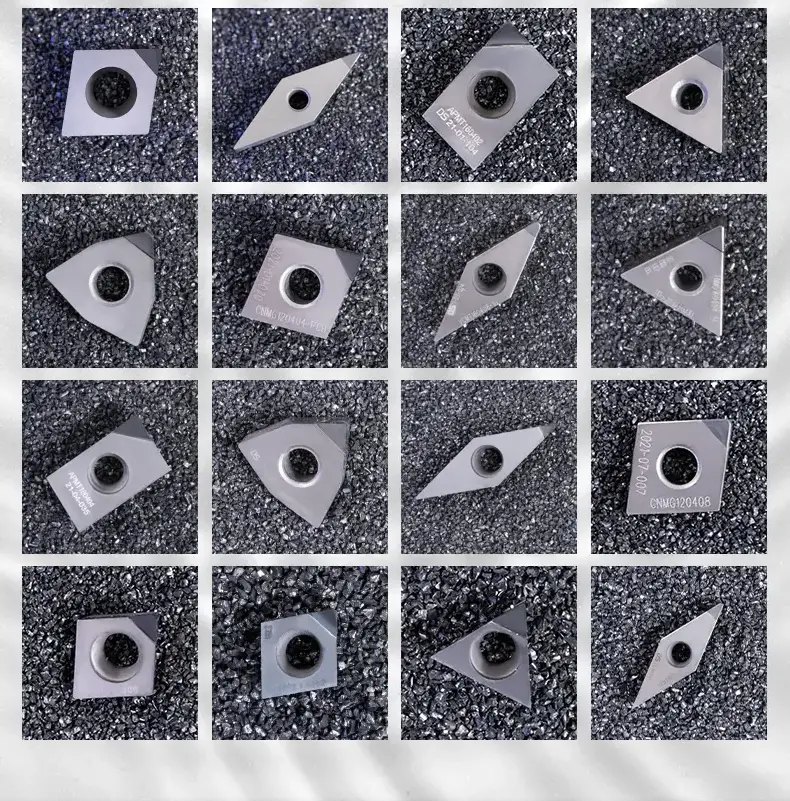

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

DS

-

Machining:

-

Finish,Semi-Finish,Roughing

-

Advantage:

-

High Efficiency, Wear-Resistant

-

Workpiece Material:

-

Steel/Copper/Aluminum/Magnesium/Zinc/Plastic

Quick Details

-

Usage:

-

Lathe Turning Tool

-

Hardness:

-

Super Hard

-

Coating:

-

PCD PCBN CBN

-

Place of Origin:

-

China

-

Brand Name:

-

DS

-

Machining:

-

Finish,Semi-Finish,Roughing

-

Advantage:

-

High Efficiency, Wear-Resistant

-

Workpiece Material:

-

Steel/Copper/Aluminum/Magnesium/Zinc/Plastic

| Diamond (PCD) | Cubic Boron Carbide (CBN) |

| Heat resistance/° | Heat resistance/° |

| 700-800 | 1400-1500 |

| Compressive strength/MPa | Compressive strength/MPa |

| 600-1100 | 500-800 |

| Fracture toughness/MPa*m*1/2 | Fracture toughness/MPa*m*1/2 |

| 9.0 | 9.0 |

| Hardness | Hardness |

| >8000HV | 3500~5000HV |

| Thermal conductivity/(W/(m*k)) | Thermal conductivity/(W/(m*k)) |

| 700 | 200-300 |

| Coefficient of thermal expansion | Coefficient of thermal expansion |

| 0.9~1.18 | 3.5~4.8 |

| PCD: aluminum and aluminum alloys, copper and steel alloys, titanium, magnesium, zinc, lead and other non-ferrous metals, glass fiber, carbon fiber reinforced plastics and other non-metals | CBN: for brown metal with extremely stable chemical properties, both hardened steel (45-65HRC) bearing steel (60-60HRC) high-speed steel (>62HRC) tool steel (57-60HRC) chilled cast iron rough turning and finishing, high-temperature alloy thermal spray material containing more than 10% of Co carbide and other difficult-to-machine materials of high-speed cutting processing |

| Aluminum and aluminum alloys | Ductile iron |

| Cutting speed | Hardness |

| 200-3000 | HB240-300 |

| Feed amount | Cutting speed |

| 0.05-0.5 | 200-400 |

| Cutting depth | Feed amount |

| 0.05-1.0 | 0.1-0.4 |

| Cutting depth | |

| 0.1-1.5 |

2. Stainless steel, steel parts, copper and aluminum, cast iron, titanium, magnesium, zinc and lead and other non-ferrous metals, glass steel and other fee metals.

3. Finishing, semi-finishing and roughing, the processed products can reach a high glossy plane without polishing.

1. Are you amanufacturer? Do you have afactory?

We are professional manufacturer with more than 15 years experience in this field.

2. Can the price be reduced for large quantities?

Yes, bigger quantity orders are cheaper.

3. Do you inspect the finished product?

Yes, every production step and finished product will be inspected by QC department before shipment.

4. What is the lead time for mass production?

Honestly, it depends on the order quantity and the season you place your order.

5. Is free shipping available?

If you buy alot of products, the shipping fee is negotiated with the factory.

6. Can you send the product to our forwarder in China?

Yes, if you have aforwarder in China, we are happy to send the product to them.

7. Can you produce special carbide tools?

Of course, we can. We will use special tools to produce according to your drawings and samples.