Rotary dryer is used to burn the hard magnetic ferrite powder; it can also be used in cement, metallurgy, chemical industry. The equipment is composed of the main kiln and its supporting transmission, cooling pipe, fuel system, electrical control, the second wind devices, exhaust dust removal device and preheating kiln body. It has the over temperature alarm, overload alarm, work automatic temperature control, and kiln oxygen adjustable functions.

- Product Details

- {{item.text}}

Quick Details

-

Applicable devices:

-

rotary kiln, ball mill, tube mill

-

Certification:

-

ISO 9001:2008

-

Packing:

-

Standared Package

-

MOQ:

-

1 Set

-

Customized:

-

yes

Quick Details

-

Weight (KG):

-

9000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yarong

-

Applicable devices:

-

rotary kiln, ball mill, tube mill

-

Certification:

-

ISO 9001:2008

-

Packing:

-

Standared Package

-

MOQ:

-

1 Set

-

Customized:

-

yes

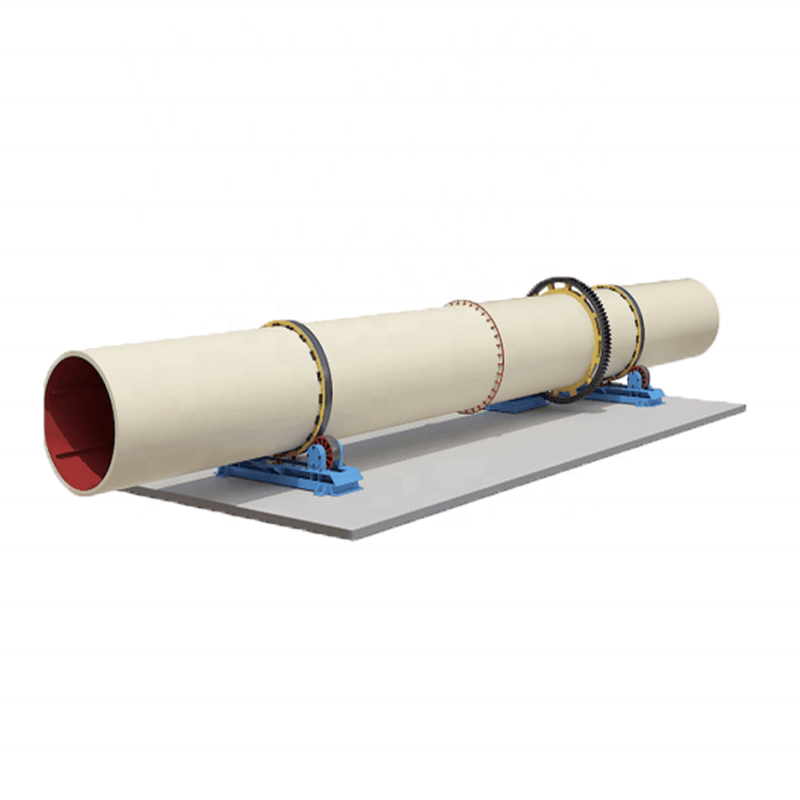

Rotary dryer

Rotary Dryer Working principle:

Wet material is input from one end of the dryer, under the copy board flip of the inner cylinder cloth, material is uniformly

distributed and dispersed in the dryer, and fully contacts with the hot air stream (countercurrent) to speed up the drying heat

transfer, and mass transfer driving force. During the drying process, the material in the copy board and the hot gas stream with

the inclination of the role, it can regulate movement to another section star-like discharge valve to discharge the finished

products.

Rotary Dryer Applications:

1. It is applied to the dry chemical, mining, metallurgy and other industries’ large particles than significant materials.

Such as: ore, blast furnace slag, coal, metal powder, phosphate, ammonium sulfate.

2. To the powder have the special requirements like: Foaming agent, lees residue, precipitated calcium carbonate, activated clay,magnetic powder, graphite, dregs.

Feature:

Require the low-temperature drying, and requires large quantities of continuous dry material.

Rotary dryer has high degree of mechanization, large production capacity.

Fluid through the cylinder the resistance is small, consumption function is low.

The strong adaptability to the material properties.

Stable operation, low operating costs and good dried product uniformity.

Wet material is input from one end of the dryer, under the copy board flip of the inner cylinder cloth, material is uniformly

distributed and dispersed in the dryer, and fully contacts with the hot air stream (countercurrent) to speed up the drying heat

transfer, and mass transfer driving force. During the drying process, the material in the copy board and the hot gas stream with

the inclination of the role, it can regulate movement to another section star-like discharge valve to discharge the finished

products.

Rotary Dryer Applications:

1. It is applied to the dry chemical, mining, metallurgy and other industries’ large particles than significant materials.

Such as: ore, blast furnace slag, coal, metal powder, phosphate, ammonium sulfate.

2. To the powder have the special requirements like: Foaming agent, lees residue, precipitated calcium carbonate, activated clay,magnetic powder, graphite, dregs.

Feature:

Require the low-temperature drying, and requires large quantities of continuous dry material.

Rotary dryer has high degree of mechanization, large production capacity.

Fluid through the cylinder the resistance is small, consumption function is low.

The strong adaptability to the material properties.

Stable operation, low operating costs and good dried product uniformity.

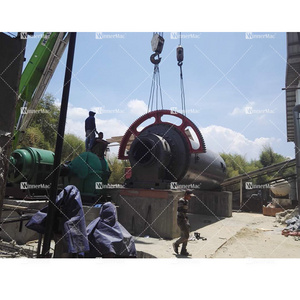

The manufacturing accuracy and assembly quality have a great impact on the generation of dynamic load, the noise during transmission, and the life of the gear, especially in the installation and maintenance process of the ball mill, the selection and adjustment of the gear pair meshing clearance of the transmission device are very important.

Installation of Ball Mill Pinion

1. Before installing the pinion, carefully check the bearing pedestal, bearing cover, rolling bearing, pinion, shaft, and other parts, remove the burrs on the gear surface, and thoroughly clean them before installation.

2. Lift the assembled pinion gear unit, and place it on the base plate stably according to the predetermined position. Strictly check the installation position of the base plate, the bearing seat, and the transmission shaft, to ensure that the gear engagement performance is good. At the same time, install the coupling half.

3. Fix the ball mill pinion gear unit and its bottom plate with bolts, paint red lead on the tooth surface of the small gear, turn the pinion shaft to make it mesh with the girth gear, and check the contact rate of the gear pair; The tooth length shall not be less than 50%, the tooth height shall not be less than 40%, the contact spot shall tend to the middle, and the backlash between girth gear and pinion shall be 1.40~2.18

1. Before installing the pinion, carefully check the bearing pedestal, bearing cover, rolling bearing, pinion, shaft, and other parts, remove the burrs on the gear surface, and thoroughly clean them before installation.

2. Lift the assembled pinion gear unit, and place it on the base plate stably according to the predetermined position. Strictly check the installation position of the base plate, the bearing seat, and the transmission shaft, to ensure that the gear engagement performance is good. At the same time, install the coupling half.

3. Fix the ball mill pinion gear unit and its bottom plate with bolts, paint red lead on the tooth surface of the small gear, turn the pinion shaft to make it mesh with the girth gear, and check the contact rate of the gear pair; The tooth length shall not be less than 50%, the tooth height shall not be less than 40%, the contact spot shall tend to the middle, and the backlash between girth gear and pinion shall be 1.40~2.18

|

Product Name

|

High Precision steel material Custom small pinion gear

|

|

Applications

|

girth gears are applied in the cement and minerals industries

|

|

Gear Cutting Machines

|

16m CNC Hobbing Machine

|

|

Diameter

|

Min 100 mm to16000 mm Gear

|

|

module range

|

10 Module to 70 Module

|

|

Maximum module

|

45 by hob

|

Hot Searches