Composition

: Feeding rollers, middle rollers, out-feeding rollers.

Loading capacity

: 2 tons per meter.

Rollers Distance:

1 m.

Rollers Speed:

0.5-4 m per min.

Drive:

Variable speed reducer.

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

- Product Details

- {{item.text}}

Quick Details

-

Power(W)::

-

customized

-

Function::

-

H beam shot blasting Cleaning

-

Application::

-

H beam Surface Cleaning

-

Power (V)::

-

220/380/400/440V

-

After-sales Service Provided:

-

Online support

-

OEM:

-

OEM Service Shot Blasting Machine

Quick Details

-

Place of Origin:

-

Shandong

-

Brand Name:

-

MeiLi

-

Weight (KG):

-

3200 KG

-

Power(W)::

-

customized

-

Function::

-

H beam shot blasting Cleaning

-

Application::

-

H beam Surface Cleaning

-

Power (V)::

-

220/380/400/440V

-

After-sales Service Provided:

-

Online support

-

OEM:

-

OEM Service Shot Blasting Machine

Why choose us?

1.

Highest quality

of our products following CE, ISO 9001 and Strict Production Guideline standard.

2.

Factory

and Competitive Price we offer.

3.Our level of after-sale service is second to none.

4.Our equipment is designed and constructed with our customer's safety as a top priority.

5.

OEM&ODM

service to meet all your requirements.

Products Description

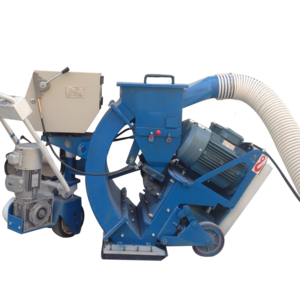

Roller Conveyor Tunnel Type Shot Blasting Machine for Building Steel and Aluminum Wheel

Roller Type Shot Blasting Machine

The series roller type shot blasting machine is a pass-through shot blasting machine used for the cleaning of steel plate, steel structure and profile. This kind of shot blasting machine can not only remove the scale and dust during welding, but also can enhance workpieces fatigue resistance, reaching the purpose of improving the inner and surface quality of steel plate

H beam shot blasting machine:

Shot blasting machine for h beam is designed and produced by adopting the advantages of similar products from both within the country and abroad. The rusting cleaning part (shot blasting) adopts high-efficient blast wheel and full shutter type shot sand

separator. The sweeping machine adopts specially made high-strength nylon rolling brush and high-pressure ventilator. The preheating and drying part of shot blasting machine may adopt various heating methods. The paint spraying part adopts high-pressure airless spraying method. The complete set of equipment is controlled by PLC, and is the large-size complete equipment of international advanced.

Q698G Plate shot blasting machine is a kind of cleaning steel plate, H steel, section steel multi-functional rust removal equipment. The conveying mode is a high efficiency shot blasting equipment for continuous feeding of straight roller channel. By electrical control in the process of cleaning roller conveyor speed will material sent to the main Chambers blasting, material into the chamber body mass ejection area, its around the surface hit by powerful dense projectile from different coordinate direction with friction, make its scale, rust layer and its dirt falls off quickly, the steel surface is bright and clean surface with certain roughness.

|

Product Name

|

Reliable In Quality High Yield Of Steel Shot Blasting Machine

|

|

Material

|

stainless steel

|

|

Color

|

nickel white、Light green

|

|

Standard

|

Custom type

|

|

Model

|

Q698G

|

|

Brand

|

MeiLi

|

|

Used

|

Plate shot blasting machine is a kind of cleaning steel plate, H steel, section steel multi-functional rust removal equipment.

|

Details Images

Advantages of roller conveyor type shot blasting machine:

1. Wide application, Easy to install and use.

3. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers).

2. Customized, Meet your needs.

4. Exquisite appearance (mature craft).

7. Factory direct selling with competitive price.

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

10. Mainly electrical control system adoptsinternational brand.

8. Over 13years' production experience.

9. Professional design team to serve you.

11.CE certificate assure you our quality.

1. Wide application, Easy to install and use.

3. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers).

2. Customized, Meet your needs.

4. Exquisite appearance (mature craft).

7. Factory direct selling with competitive price.

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

10. Mainly electrical control system adoptsinternational brand.

8. Over 13years' production experience.

9. Professional design team to serve you.

11.CE certificate assure you our quality.

Roller Conveyor Systems

Blasting Chamber

Composition

: Main blasting chamber, 2 auxiliary blasting chambers. Auxiliary Blasting Chamber:Four layers rubber curtains

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

Abrasive Recycling System

Longitude Screw:

collect abrasive at the bottom.

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator: Separate & get qualified abrasive

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator: Separate & get qualified abrasive

Manufacturing Technique

Shot blasting and painting line machine for industrial workpiece surface cleaning

Q69 Steel Profiles shot blasting machines are used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery,etc.By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked.

This ensures a flexible manufacturing process and high material output.

Product packaging

Hot Searches