- Product Details

- {{item.text}}

Quick Details

-

Theoretical Shot Volume(cm³):

-

120 cm³

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

30 g

-

Screw diameter (mm):

-

120 mm

-

Weight (KG):

-

1200 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

LSR

-

Brand Name:

-

TRIMER

-

Power (kW):

-

11 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Vertical Plastic Injection Moulding Machine

-

Plastic Type:

-

ABS.AS.PS.HIPSPP.LDPE.HDPE.PMMD.PA6.POM.PCPVC.PET.PBT. TPE(PE)

-

Application:

-

Inserting Plastic Products

-

Product:

-

PP PVC ABS TPE

-

Injection Molding Machine Classification:

-

PET Preform Making Injection Molding Machine

-

Plastic injection moulding machine:

-

Vertical Led Machinery

-

Key Words:

-

Servo Motor Plastic Injection Molding Machine

-

Usage:

-

Plastic Product Molding

Quick Details

-

Mold Height(mm):

-

200 - 350 mm

-

Ejector Stroke(mm):

-

350 mm

-

Ejector Force(kN):

-

80 kN

-

Theoretical Shot Volume(cm³):

-

120 cm³

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

30 g

-

Screw diameter (mm):

-

120 mm

-

Weight (KG):

-

1200 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

LSR

-

Brand Name:

-

TRIMER

-

Power (kW):

-

11 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Vertical Plastic Injection Moulding Machine

-

Plastic Type:

-

ABS.AS.PS.HIPSPP.LDPE.HDPE.PMMD.PA6.POM.PCPVC.PET.PBT. TPE(PE)

-

Application:

-

Inserting Plastic Products

-

Product:

-

PP PVC ABS TPE

-

Injection Molding Machine Classification:

-

PET Preform Making Injection Molding Machine

-

Plastic injection moulding machine:

-

Vertical Led Machinery

-

Key Words:

-

Servo Motor Plastic Injection Molding Machine

-

Usage:

-

Plastic Product Molding

Products Description

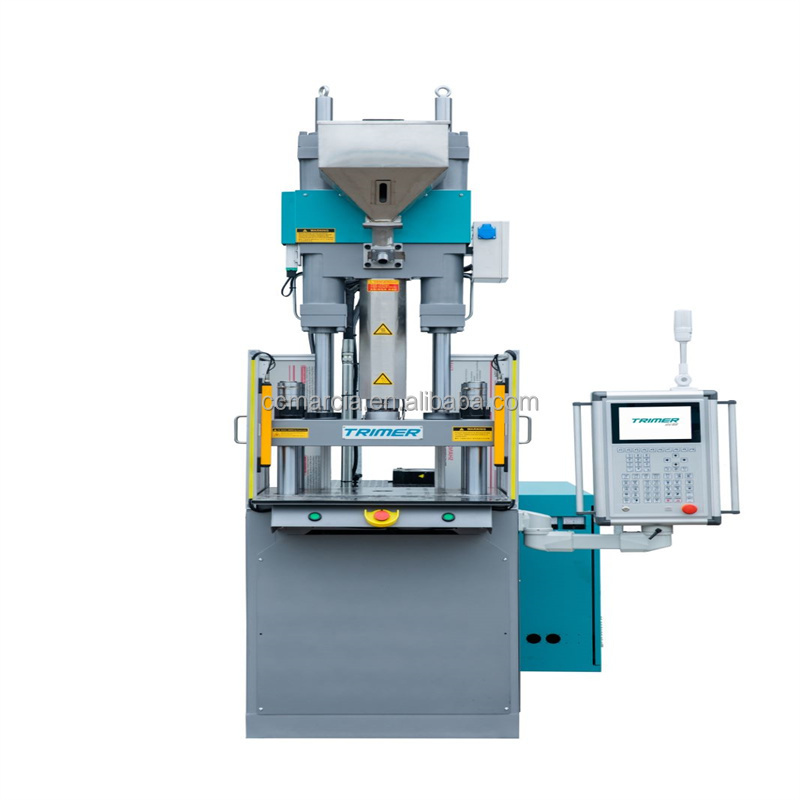

VRE series oil electric composite vertical injection molding machine

Standard configuration

Electric drive: injection, material storage, turntable.

Servo hydraulic drive: mold opening and closing, seat forward and backward, ejector pin, and core pulling.

Provide a set of core pulling for one upper mold and two lower molds.

The water distribution tower in the center of the turntable can be connected to cooling water or hot oil.

The automatic lubrication system provides sufficient lubrication for the electric drive injection unit.

Alloy screw material pipes for engineering plastics.

The nozzle buffer device helps to reduce nozzle and mold wear.

Real time monitoring of injection pressure and storage back pressure for imported Load Cell.

12 inch human-machine interface, providing two operation modes: touch screen and commonly used buttons.

New advanced high stable vertical injection molding machine made in China.

Whatsapp 0086 136 1618 7265

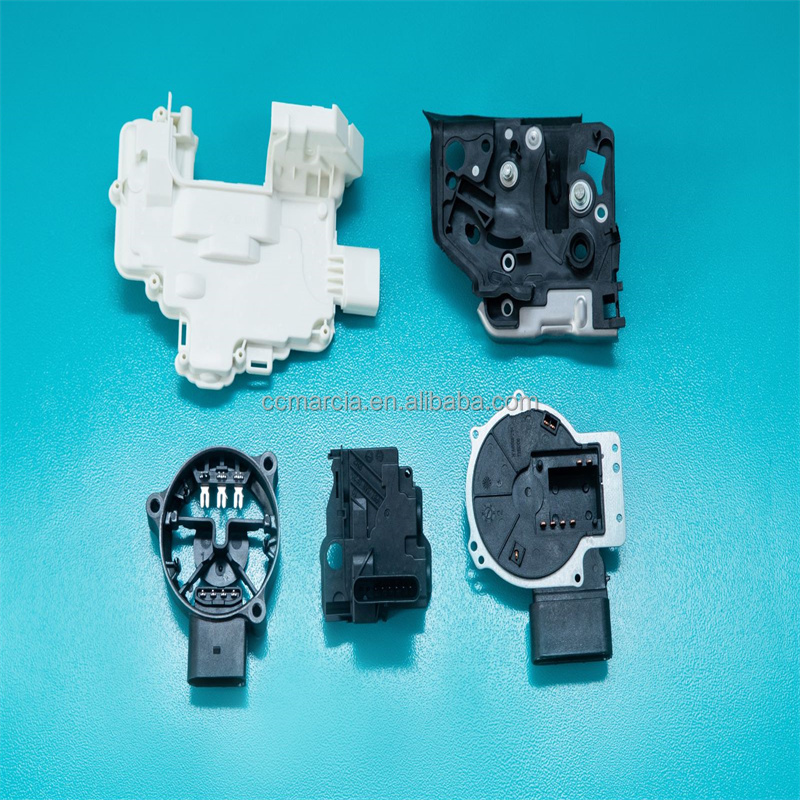

Application

two colors process for tools handle

made by vertical injection machine

professional injection machine for glasses

vertical injection machine for making

electric parts with embedding process

China factory Vertical Thermoplastic Moulding Injection Molding Machine

plastic injection molding machine

Plastic Products Manufacturing Machine vertical injection molding machine

All Kinds Of Thermoplastic Liquid Plastic Molding Bait Fishing

Gear Vertical Injection Molding Machine

Gear Vertical Injection Molding Machine

Best Price Hydraulic Vertical Plastic Injection Molding Machine

Thermoplastic Vertical Plastic Syringe Injection Blow Molding Machine

CNC injection molding machine

Best Price High Configuration Plastic EVA Injection Molding Machinery

Plastic Rubber Plug Cover Screw Bolt Making for Small Vertical Injecting Molding Machine

Car Air Filter Vertical Injection Molding Machine

injection plastic mould machine desktop moiron desktop injection molding machine

Semi Automatic Vertical 35 Ton Manual Mini Plug Power Cord USB Data Cable Injection Molding Machine

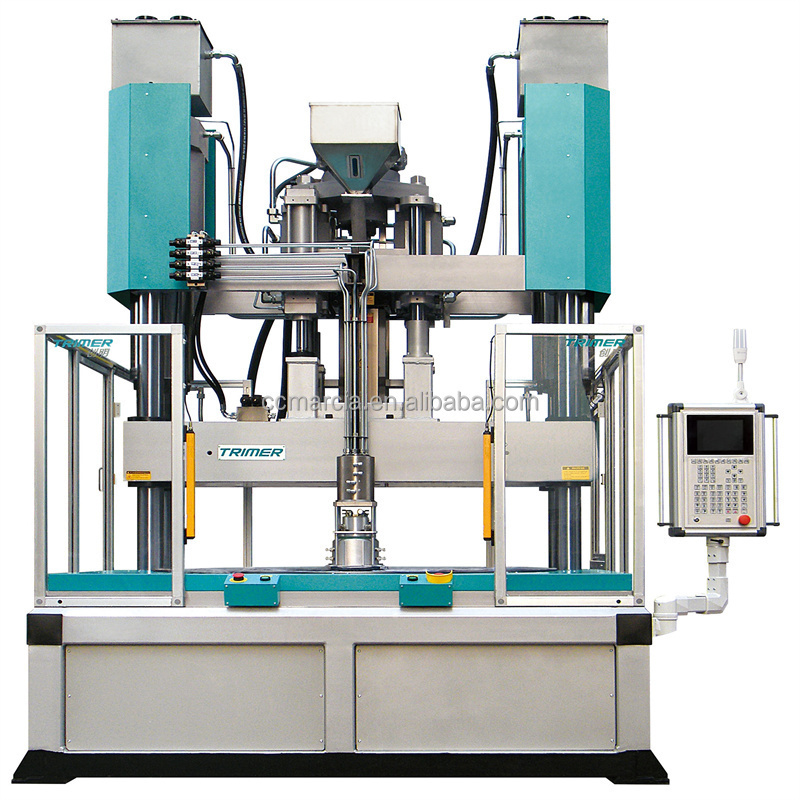

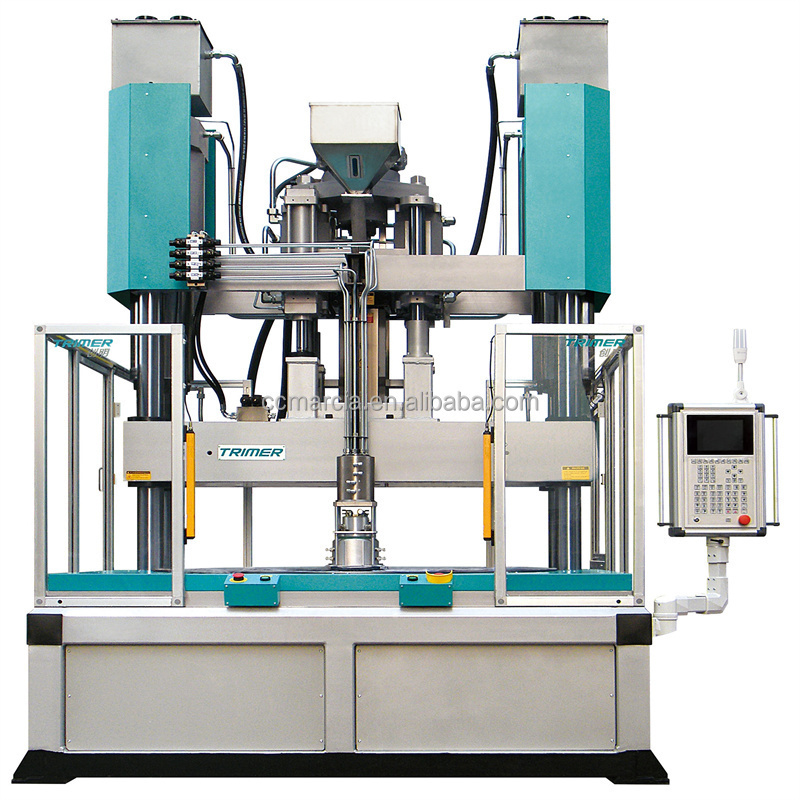

Special Machine Introduction

Liquid silicone rubber injection molding machine

special injection molding machine for making different LSR products

Machine features of Liquid silicone rubber injection molding machine

1.Specially designed injection unit is more suitable for LSR processing.

2.Adjustable multi-stage precision mold electrothermal temperature control.

3.Special water-cooled closed nozzle for LSR.

4.Special water-cooled screw and barrel for LSR.

5.Optimized design of the insulation board to prevent heat loss.

6.Double Sliding/Rotary table design, convenient, improve safety and

improve production efficiency 30%-50%.

7.Optional servo system, energy saving, precision and fast response.

8.Optional vacuum device to prevent product bubble

FAQ

Vertical injection machine is the customized service , please feel free to contact with us and share your detailed requirement as below :

What kind of plastic products do you make ?

How about your requirement for the productivity ?

Hydraulic oil type or electricity ?

etc

Any request , please talk with us whatsapp 0086 136 1618 7265

Recommend Products

Hot Searches