SXZG Series press brake features the crowning system for improved quality, a servo driven back gauge system for increased speeds.

Also has increased working speeds, stroke, daylight, and pressing capacities of machines. The future - as a result of rising energy costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

This series is fully in accordance with European standards, high precision, high security.

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

200 mm

-

Dimension:

-

2500*1800*2000

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Weight (KG):

-

5000

-

Motor Power (kw):

-

5.5 kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Sheet / Plate Rolling

-

machine type:

-

hand folder mild steel bending hydraulic press brake machinery

-

Color:

-

Optional

-

voltage:

-

380v 220v 415v

-

CNC or not:

-

CNC BendingMachine

-

Function:

-

Steel Metal Bending

-

Control system:

-

DA53t

-

Electrical components:

-

Schneider

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

2200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

200 mm

-

Dimension:

-

2500*1800*2000

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Weight (KG):

-

5000

-

Motor Power (kw):

-

5.5 kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Sheet / Plate Rolling

-

machine type:

-

hand folder mild steel bending hydraulic press brake machinery

-

Color:

-

Optional

-

voltage:

-

380v 220v 415v

-

CNC or not:

-

CNC BendingMachine

-

Function:

-

Steel Metal Bending

-

Control system:

-

DA53t

-

Electrical components:

-

Schneider

4mm 6mm ss iron plate metal sheet 2200mm 40 ton small mini servo hydraulic press brake

mini servo hydraulic press brake

Product Overview

CNC PRESS BRAKE

DELEM DA53T Controller

1. 10.1'' LCD TFT colour display

2. Bend sequence determination

3. Developed length calculation

4. Crowning control

5. Servo, frequency inverter and AC control

6. Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

2. Bend sequence determination

3. Developed length calculation

4. Crowning control

5. Servo, frequency inverter and AC control

6. Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

|

Item

|

40T1600

|

|

Pressure

|

400

|

|

Worktable length

|

1600

|

|

Pole distance

|

1300

|

|

Throat depth

|

250

|

|

Slider strokes

|

120

|

|

Max open height

|

460

|

|

Motor

|

5.5

|

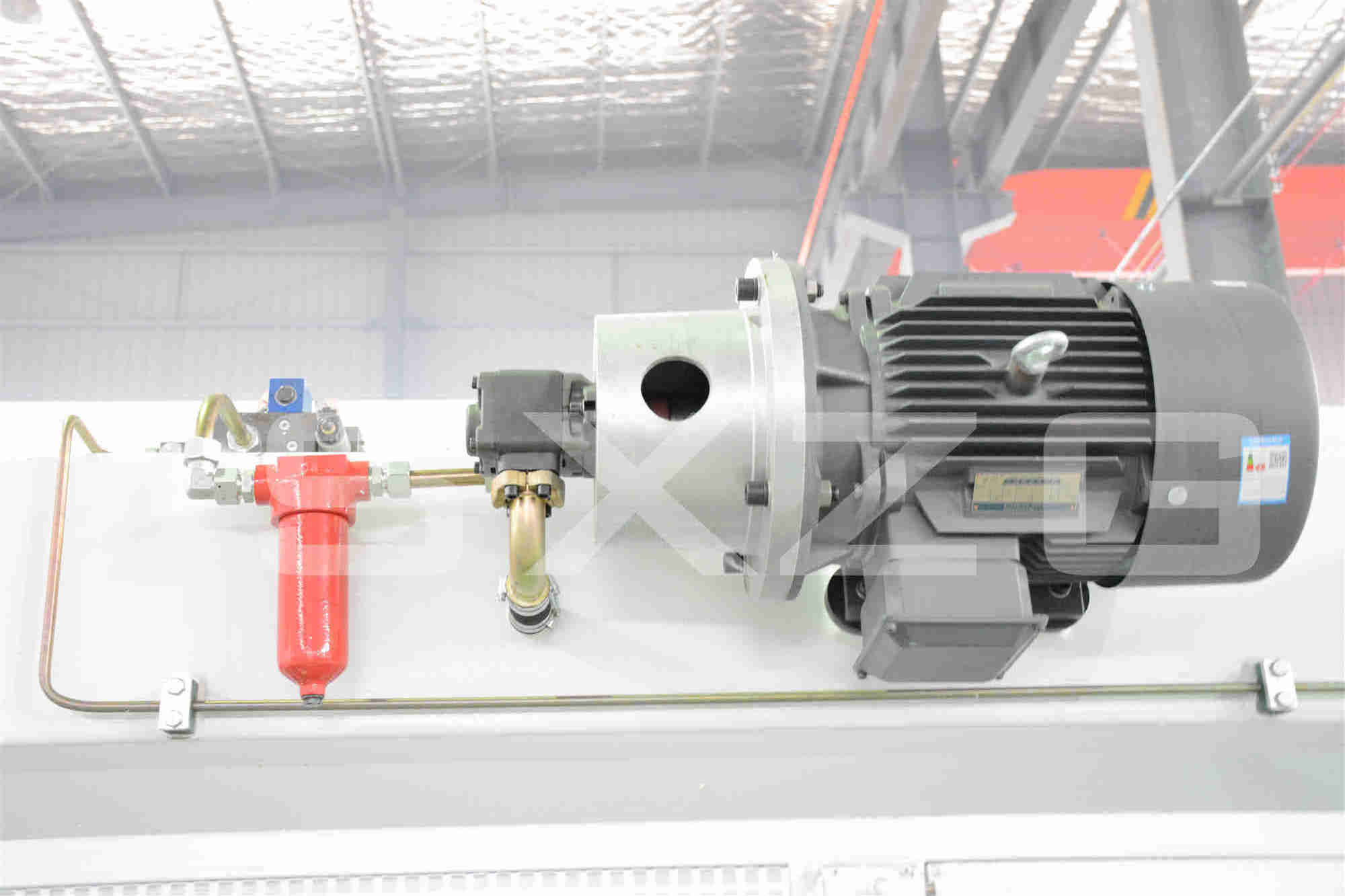

PRODUCT CONFIGURATION

SIEMENS MOTOR

Germany famous brand motor improves the lifespan of the and keeps the machine working in low noise environment

Bosch Rexroth hydraulic Valve

Germany Bosch Rexroth integrated hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid

Ball Screw And Linear Guide Rall

Using Taiwan HAWKINGS Ball Screw and linear guider to improve the machine backgauge accurancy

Germany EMB tube

Using Germany EMB tube and connectors reduce the odds against welding slag jam into the valves and affect oil flowing

Fast clamp

Very easy to change toolings

Mechanical Crowning

Optional electric mechanical crowning, improving the precision of bending angle and linearity

Optional Components

Backgauge up and down

Optional Servo motor drive R Axis-Backgauge up and down

Hydraulic Crowning

Optional hydraulic crowning, improving the precision of bending angle and linearity

Main Motor Sevo Motor

Save electricity costs; Low noise; Low oil temperature, extend the life of the seal

Italy DSP Laser protection

Optional Italy DSP laser protection, protecting the workers' fingers

Optional Segment Die

Press brake segmented die are available for your choice

Press brake segmented die are available for your choice

Tooling and samples

Packaging and Delivery

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer of pipe tube processing.

Q2: How long is your delivery time?

A2: The standard model is 15-30 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: The thickness, width and material.

4. Q: What is your term of payment ?

A:30% T/T in advance, the balance before shipment.

Q2: How long is your delivery time?

A2: The standard model is 15-30 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: The thickness, width and material.

4. Q: What is your term of payment ?

A:30% T/T in advance, the balance before shipment.

Related Products

Hot Searches