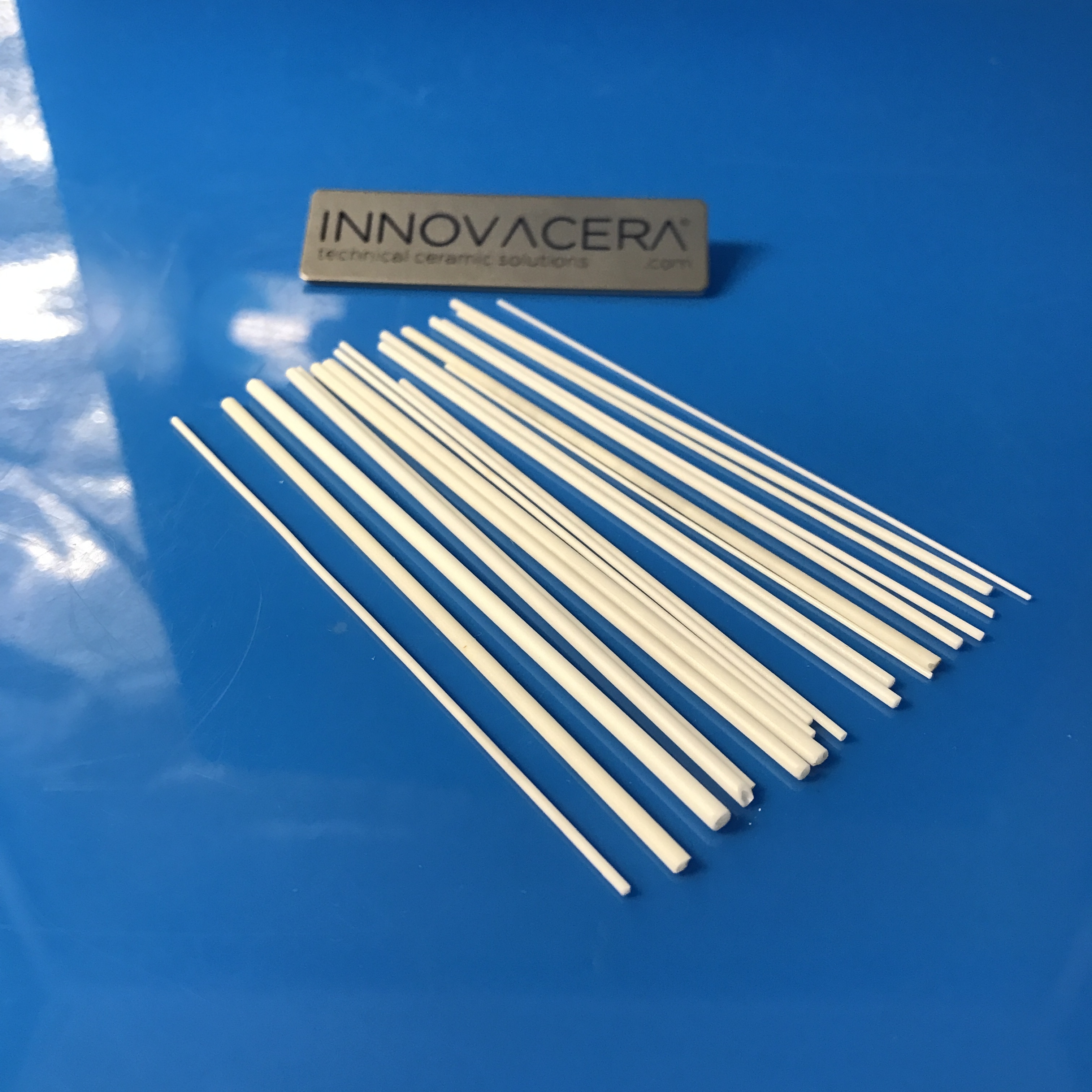

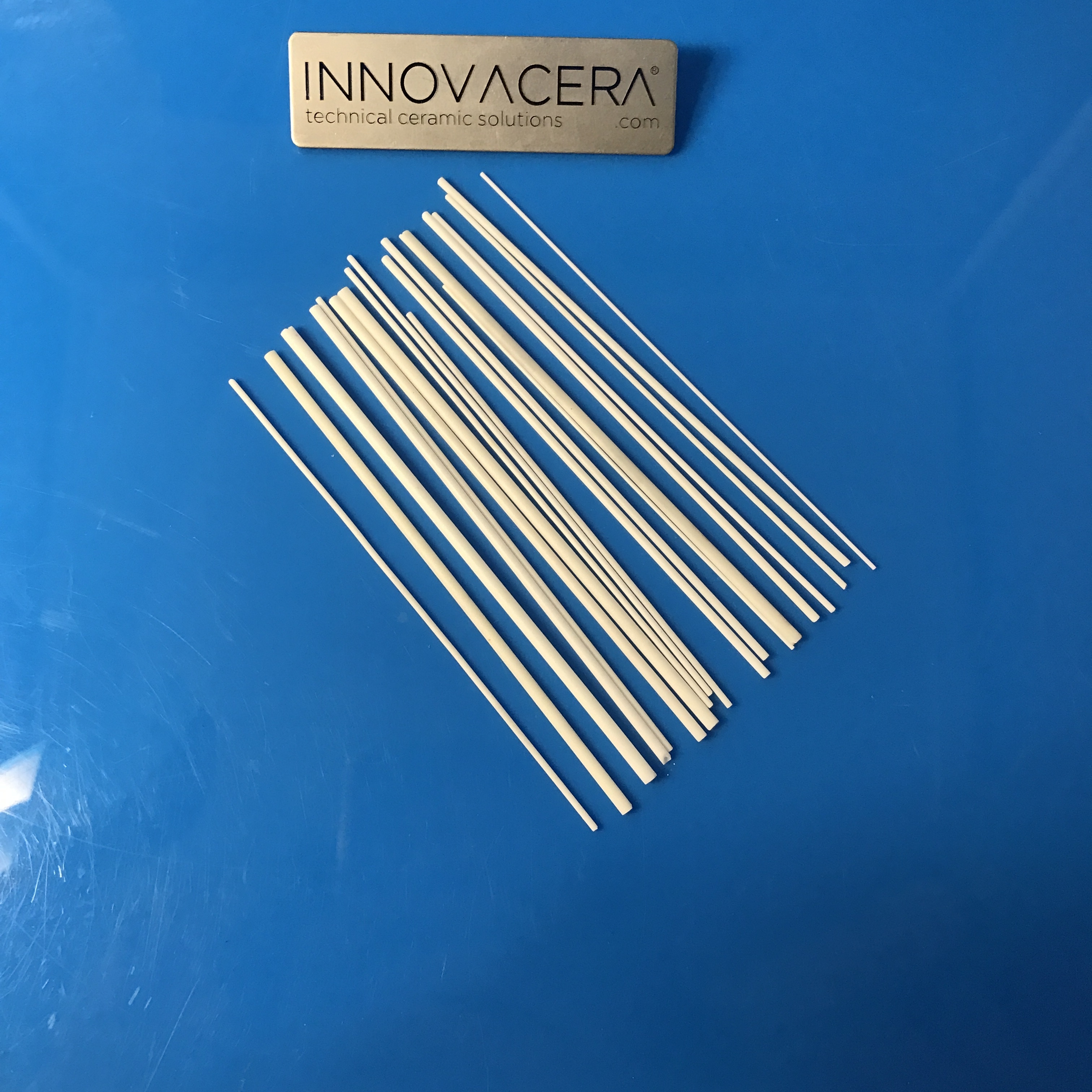

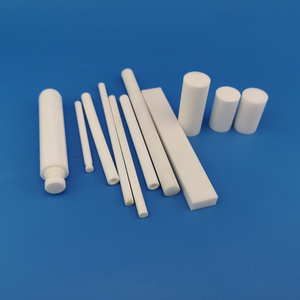

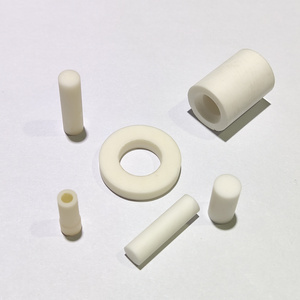

1.Purity:92%, 95%, 96%, 99%, 99.7%

2.Good mechanical strength

3.Excellent electrical insulation

4.High-frequency loss

5.Good thermal conductivity

6.Heat, wear and corrosion resistance.

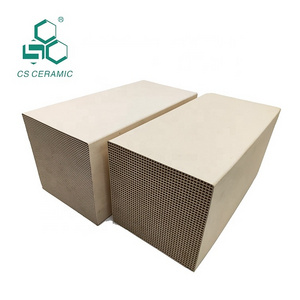

3.Excellent electrical insulation

4.High-frequency loss

5.Good thermal conductivity

6.Heat, wear and corrosion resistance.