- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BTMA

-

Weight:

-

5800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Jaw Crusher Machine

-

After-sales Service Provided:

-

24H On-Line Support

-

Usage:

-

Crushing Work

Quick Details

-

Application:

-

Mining Quarry Building Construction

-

Capacity(t/h):

-

Max.52 t/h

-

Place of Origin:

-

Henan

-

Brand Name:

-

BTMA

-

Weight:

-

5800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

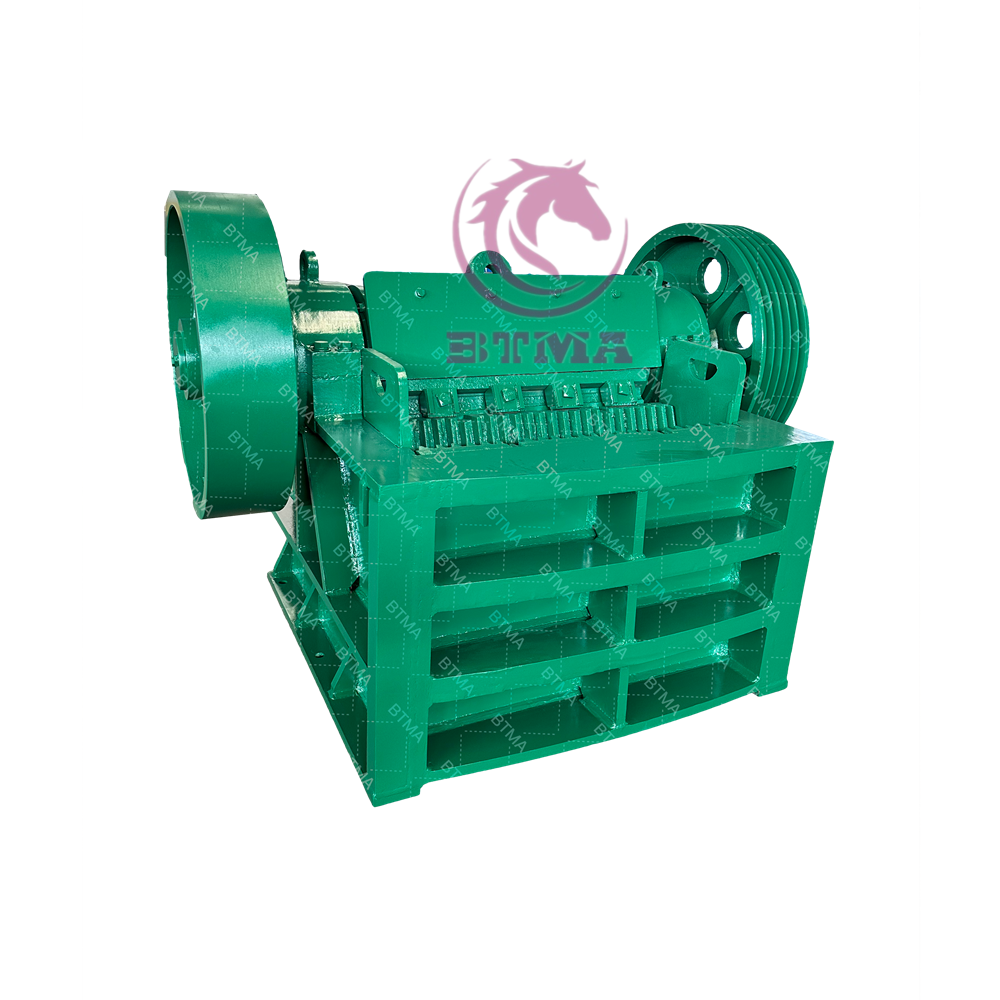

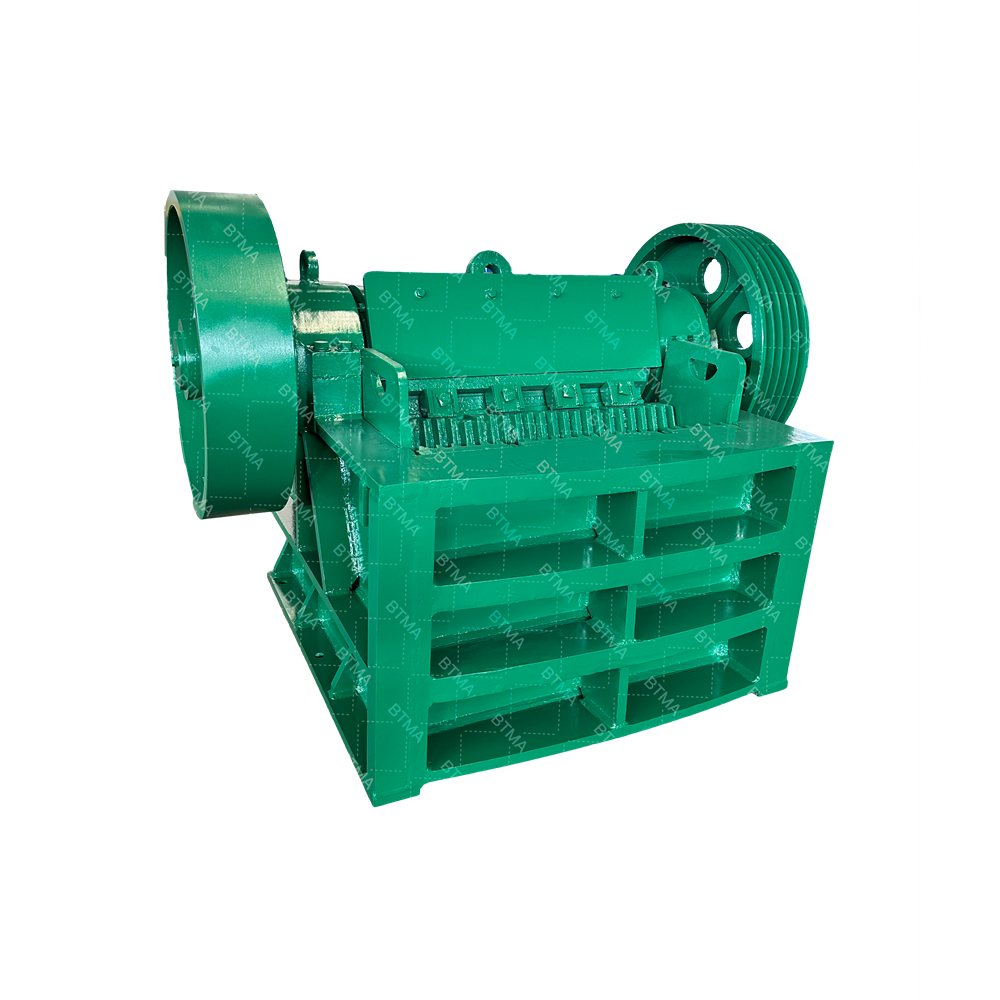

Jaw Crusher Machine

-

After-sales Service Provided:

-

24H On-Line Support

-

Usage:

-

Crushing Work

PEX series fine jaw crusher with reversible jaw plate and heat treated forged eccentric shafts on sale

Products Description

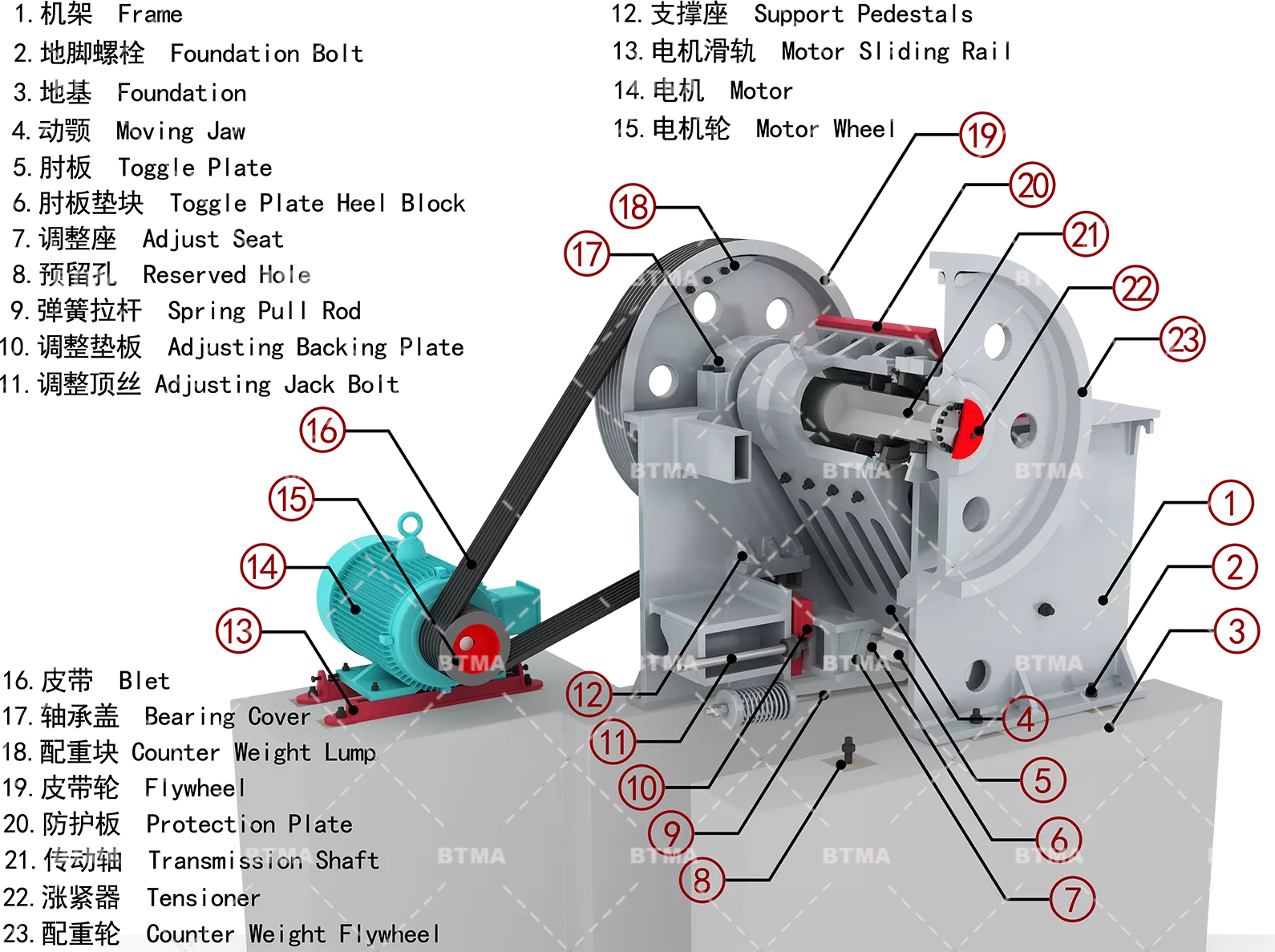

Fine Jaw crusher is typically used as Secondary crushers, or the second step in the process of reducing rock. They typically crush using compression. The rock salt lump is dropped between two rigid pieces of metal, one of which then move inwards towards the rock,and the rock salt lump is crushed because it has a lower breaking point than the opposing metal piece. Jaw crusher movement is obtained by using a pivot point located at one end of the "swing jaw", and an eccentric motion located at the opposite end.

BTMA stone crusher machine, a type of jaw crusher is widely used in mining, railway construction, water conservancy project, metallurgy, chemical, building material industries. It is mainly used to crush rock and ore, whose compression strength is less than 320 Mpa. Jaw crusher, your preferred primary crusher, is used for coarse crushing and fine crushing.

Structure of jaw crusher

Details Images

Working Principle

Our Advantages

* Model for the latest products, a wide range of applications, with a compact structure, long service life, and high work efficiency.

*

High capacity, less costly ,Easy to install and

Energy saving, one jaw crusher can save energy of 15%-30%.

*

The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of materials

* First-class technology, reliable pre-sale customer service quality. The products meet European CE certification standards.

Delivery

Hot Searches